Assembled building wall

A building wall and assembly technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of not being able to temporarily fix, not setting horizontal cover grooves and vertical cover grooves, and not being able to improve the work efficiency of staff, and achieve The overall performance of the building is strong, the structure is scientific and reasonable, and the effect is safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

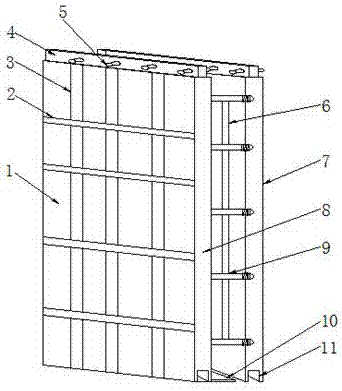

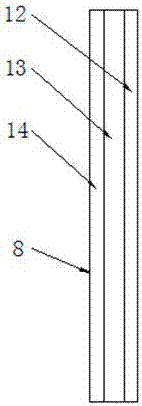

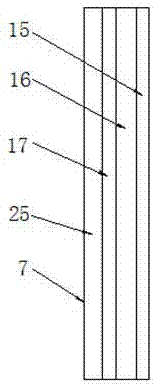

[0024] Example: such as Figure 1-6 As shown, the present invention provides a technical solution, a prefabricated building wall, including a transfer wall body 1, a horizontal cover groove 2, a vertical cover groove 3, splicing protrusions 4, limit columns 5, reinforcing ribs 6, Outer wall 7, inner wall 8, spacing adjustment bolt 9, bottom plate 10, limit slot 11, flame retardant layer 12, heat preservation layer 13, moisture-proof layer 14, decorative layer 15, soundproof cotton layer 16, building substrate 17, thread Head 18, binding wire 19, clamping plate 20, card slot 21, pressing head 22, telescopic column 23, spring 24 and connecting plate 25, one side of transfer wall body 1 is provided with outer wall body 7, and the other side is provided with The inner wall 8 is provided with a base plate 10 at the bottom of the inner wall 8, and the upper end of the inner wall 8 is provided with a splicing protrusion 4, and the connection between the inner wall 8 and the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com