Split type air jet loom temple roller shaft seat

An air-jet loom, split technology, applied in the directions of textile, textile, papermaking, weaving auxiliary equipment, etc., can solve the problems of reducing the economic benefits of enterprises, large equipment cost expenditure, affecting production progress, etc., achieving simple structure and reducing equipment. cost, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

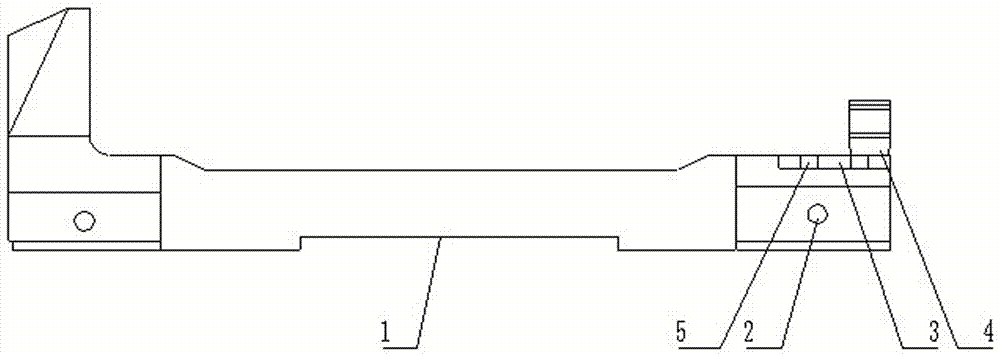

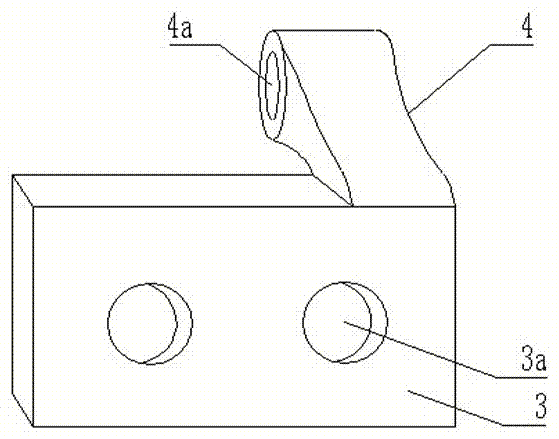

[0017] Such as figure 1 , figure 2 As shown, a split-type air-jet loom temple thorn shaft seat of the present invention includes a temple thorn shaft main seat 1, and one end of the temple thorn shaft main seat 1 is provided with a square base 3, and the outer end of the square base 3 is Hanging lugs 4 are provided, and the hanging lugs 4 are provided with temple thorn rings 4a; the two ends of the temple thorn shaft main base 1 are also provided with screw holes 2 .

[0018] The square base 3 is fixed on the temple thorn shaft main base 1 by bolts 5 .

[0019] The bolts 5 are provided in a pair.

[0020] The invention is a metal component, which is convenient to manufacture and has a long service life. During installation, after the bolt 5 is inserted through the positioning hole 3a, the square base 3 is fixed on the main seat 1 of the temple barbed shaft; after that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com