Automatic connected pad printing machine

A pad printing machine, automatic technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of wasting manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

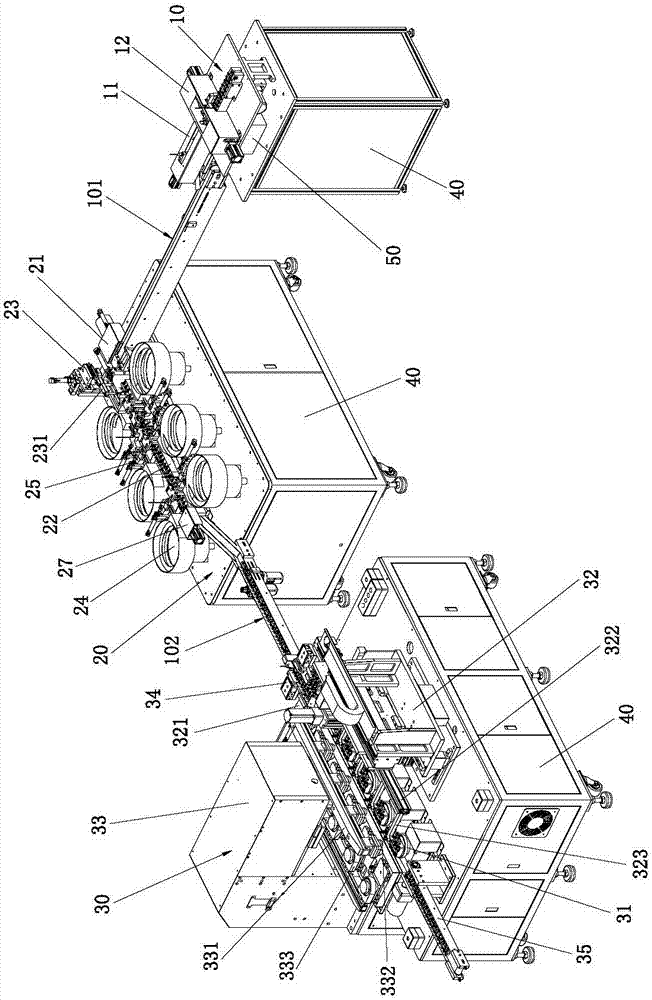

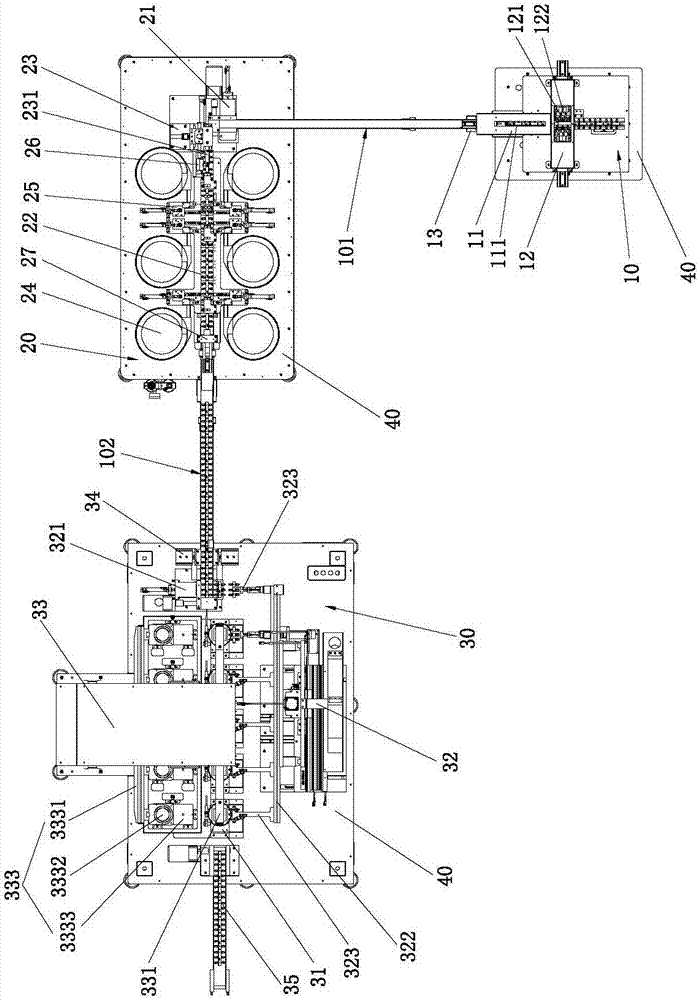

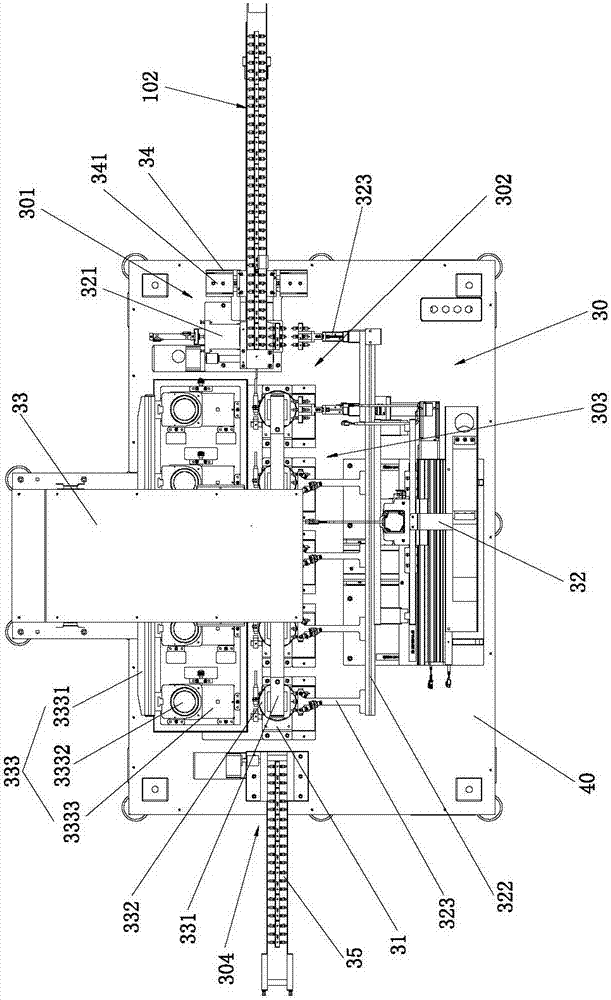

[0061] Please refer to Figure 1-Figure 8 Shown, it has shown the concrete structure of two kinds of embodiments of the present invention, wherein, Figure 1-7 Shown mainly shows the concrete structure of embodiment one, Figure 8 The shown mainly shows the partial structure of Embodiment 2; it includes an automatic conveying jig unit 10, an automatic workpiece loading unit 20, and an automatic pad printing unit 30 connected sequentially in sequence; the automatic pad printing unit 30 includes sequentially connected input Material area 301 , pad printing area 303 and finished product output area 304 .

[0062] Specifically, the pad printing area 303 has a plurality of jig placement rotary platforms 31 arranged side by side at intervals, and a jig transfer device 32, The pad printing device 33 ; the jig transfer device 32 is connected between the feeding area 301 , the rotating platform 31 for placing each jig and the finished product output area 304 .

[0063] Between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com