Carbon fiber reinforced polyetheretherketone composite material and preparation method thereof

A technology of polyether ether ketone and composite materials, applied in chemical instruments and methods, synthetic resin layered products, textiles, etc., can solve problems such as difficulty in layering, achieve easy bending of layers, ensure continuity, and form methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

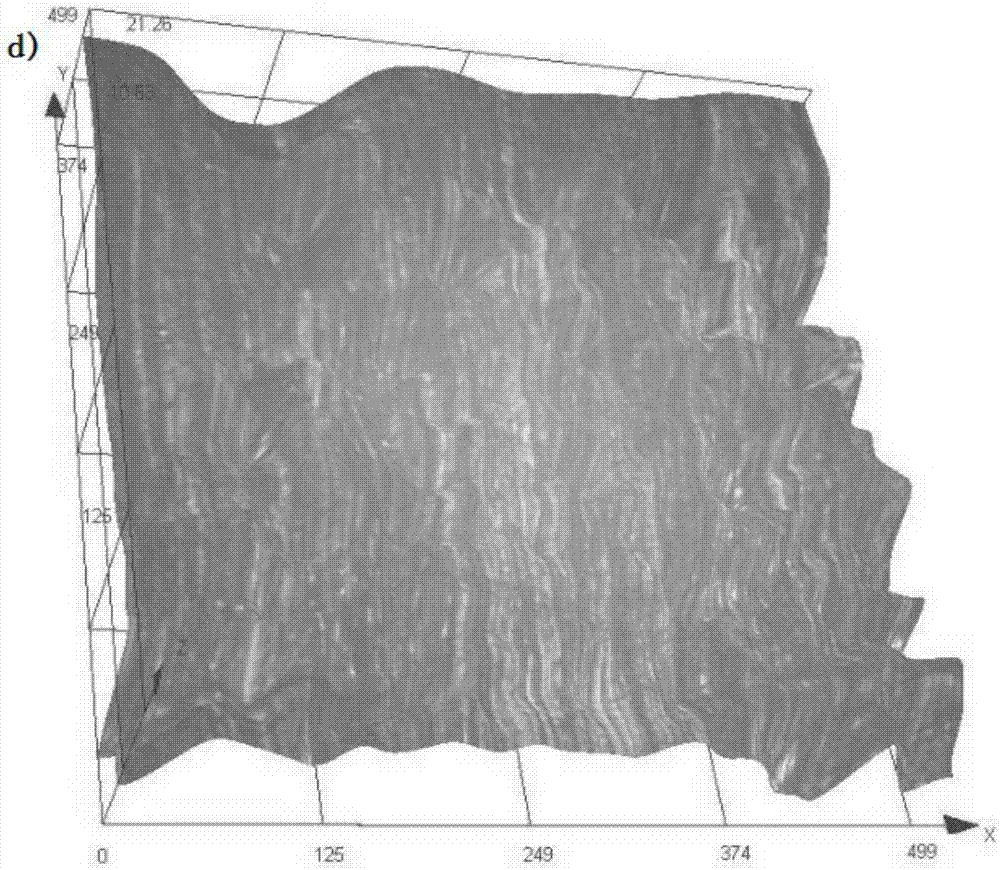

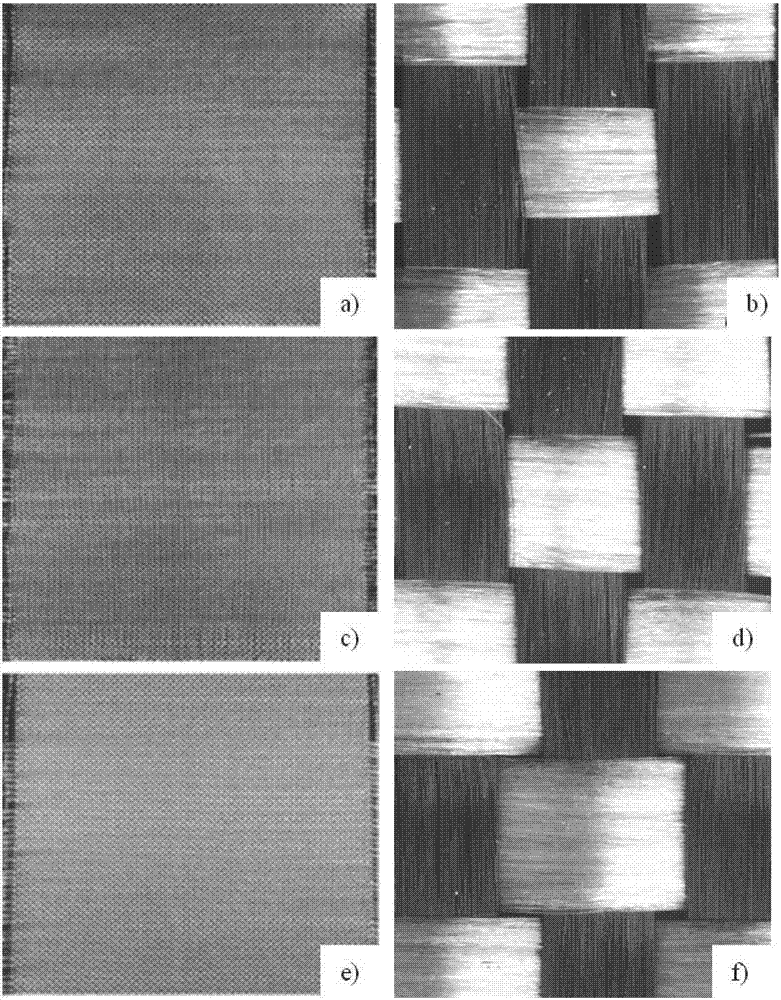

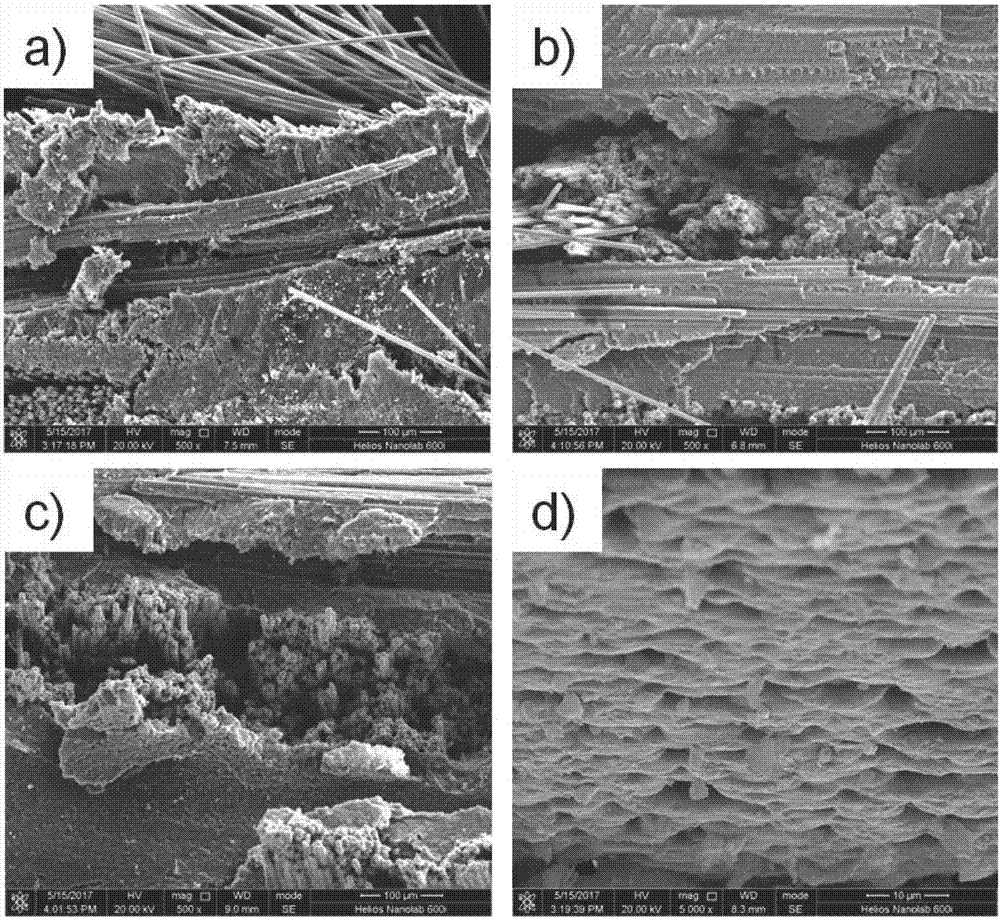

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment 1: The carbon fiber used in this embodiment is the T300 carbon fiber provided by Harbin FRP Research Institute; the polyether ether ketone filament is purchased from Changzhou Chuangying New Material Technology Co., Ltd., the model is 200D36F; a small hand-knitting machine is used to carry out Plain weave.

[0026] In this embodiment, the preparation method of carbon fiber reinforced polyetheretherketone composite material is specifically carried out according to the following steps:

[0027] Step 1. Use plain weave to weave carbon fiber and PEEK fiber and then cut them. The warp yarn is carbon fiber, the weft yarn is PEEK fiber, and the number of PEEK fiber strands is 6 strands, 12 strands or 18 strands respectively. Strand, obtains mixed weaving flexible premix;

[0028] Step 2. Lay the mixed-knitted flexible premix obtained in step 1. A total of 8 layers are laid, wherein the unidirectional carbon fibers of any adjacent two layers are set at an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com