Five-axis machining center and stone machining method thereof

A five-axis machining center, Y-axis technology, applied in the direction of stone processing tools, stone processing equipment, processing models, etc., can solve the problems of inability to process complex graphics and negative surface patterns, reduce work efficiency, increase labor intensity, etc. High-volume mass production, reduced fixture and tool costs, and the effect of saving fixtures and special tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

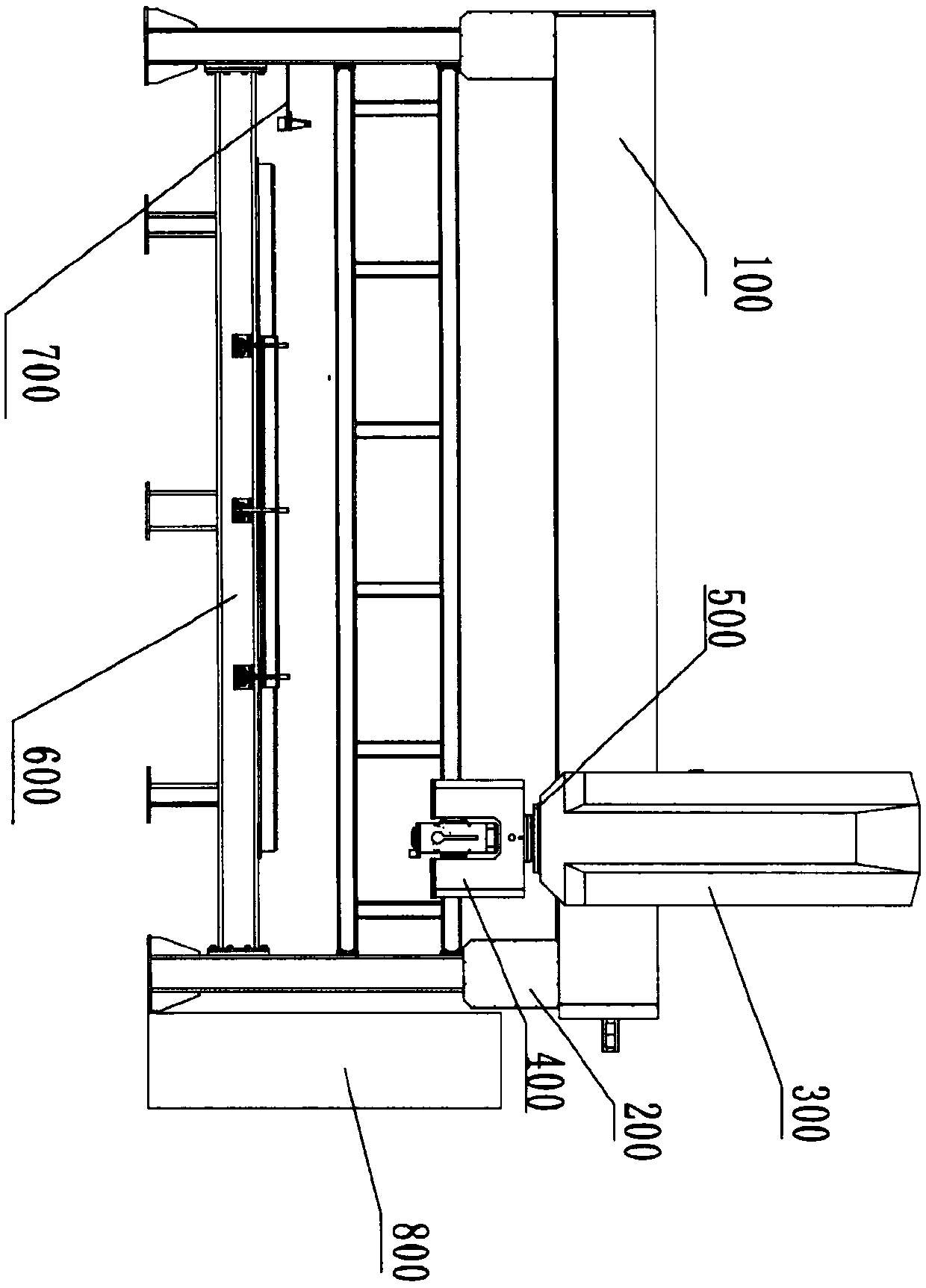

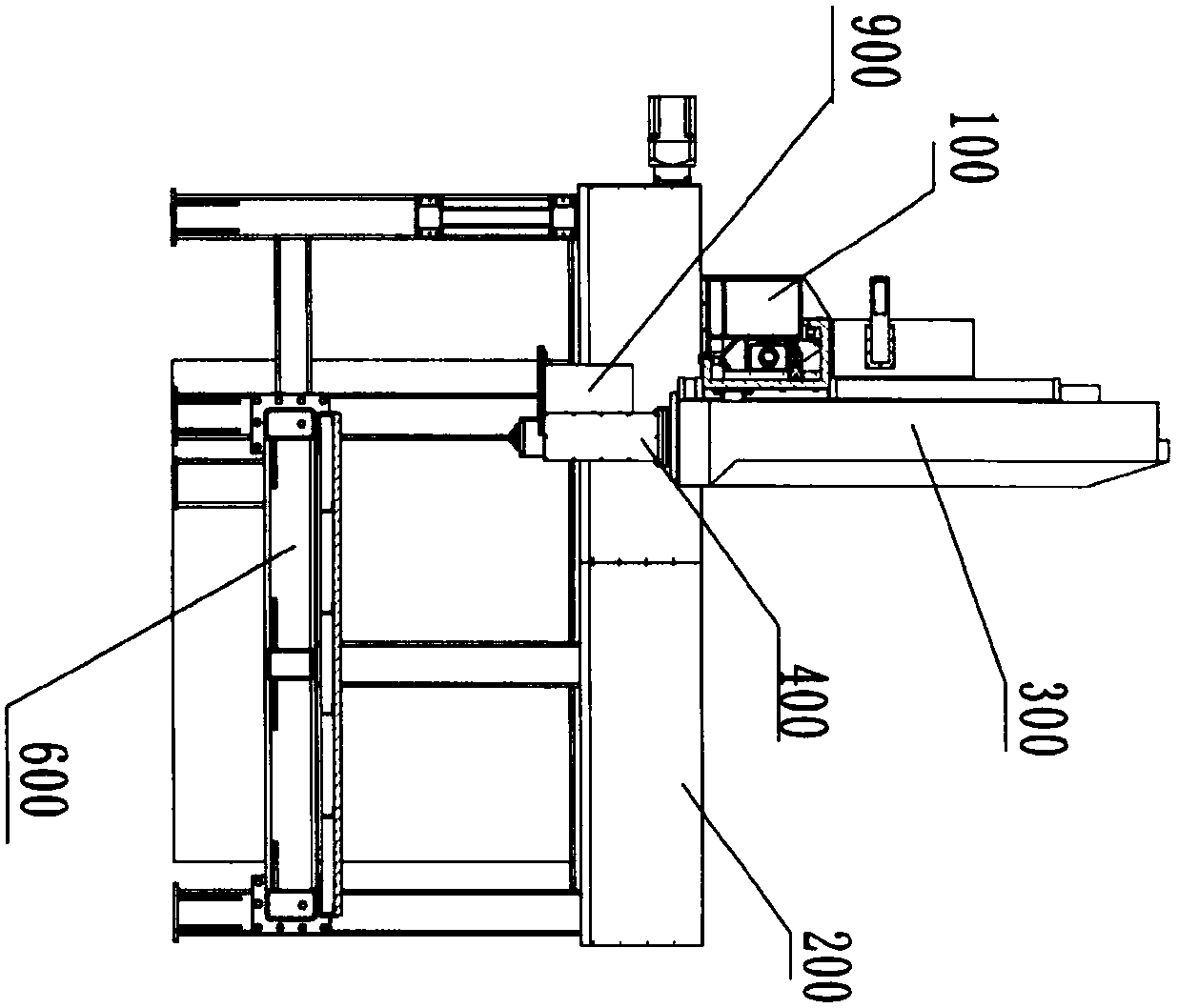

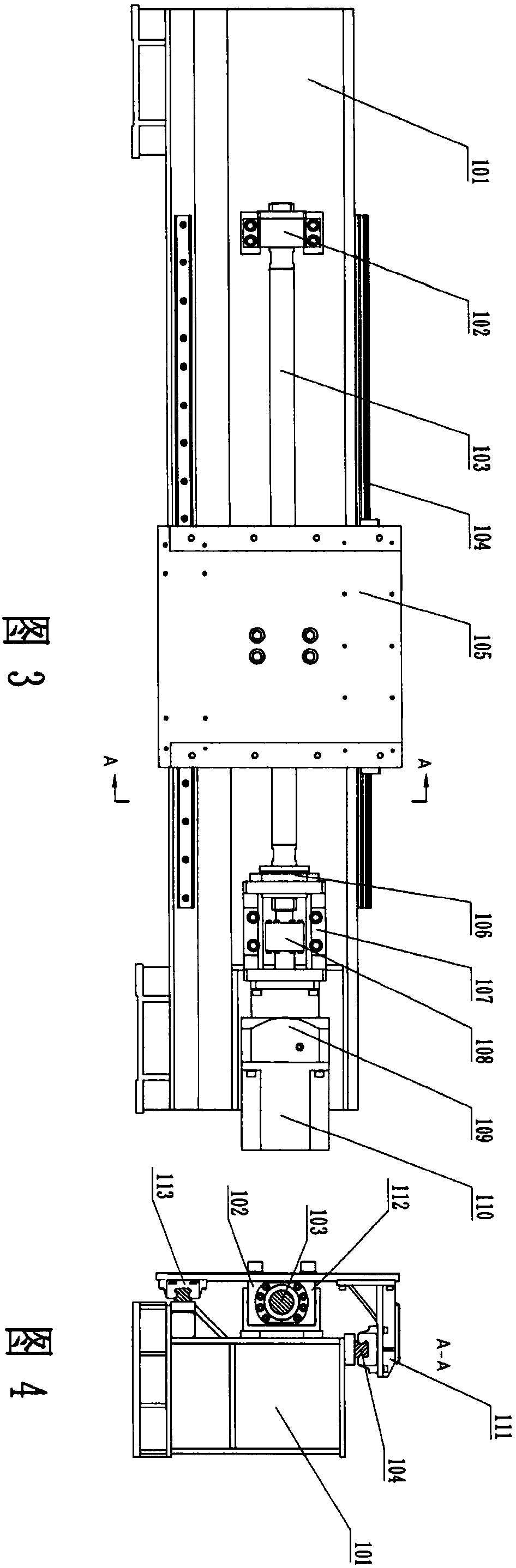

[0079] Depend on Figure 1-Figure 19 It can be seen that the present invention is a five-axis linkage structure composed of X-axis, Y-axis, Z-axis, C-axis, and B-axis. The main body of the frame is a gantry structure; The Y-axis base 212 on the top is provided with a Y-axis 200 vertically; the X-axis 100 is arranged horizontally on the beam, and the beam 101 is connected across a pair of Y-axis slides 206; a Z-axis slide is fixed on the X-axis slide 311, the lower end surface of the vertically arranged Z-axis body is fixedly connected to the upper end surface of the base in the C-axis, the C-axis output disk 506 is connected to the U-shaped head 401 in the B-axis, and the U-shaped head 401 is connected to the U-shaped head 401 through the connecting flange 406 The spindle motor 402 on which the tool is mounted is connected. A vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com