A control method and device for a laser welding machine with a head and a tail centering camera

A technology of laser welding machine and control method, which is applied to laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of strip deviation and inability to distinguish secondary shearing edge wires, so as to eliminate interference and eliminate detection data. Inaccurate, labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

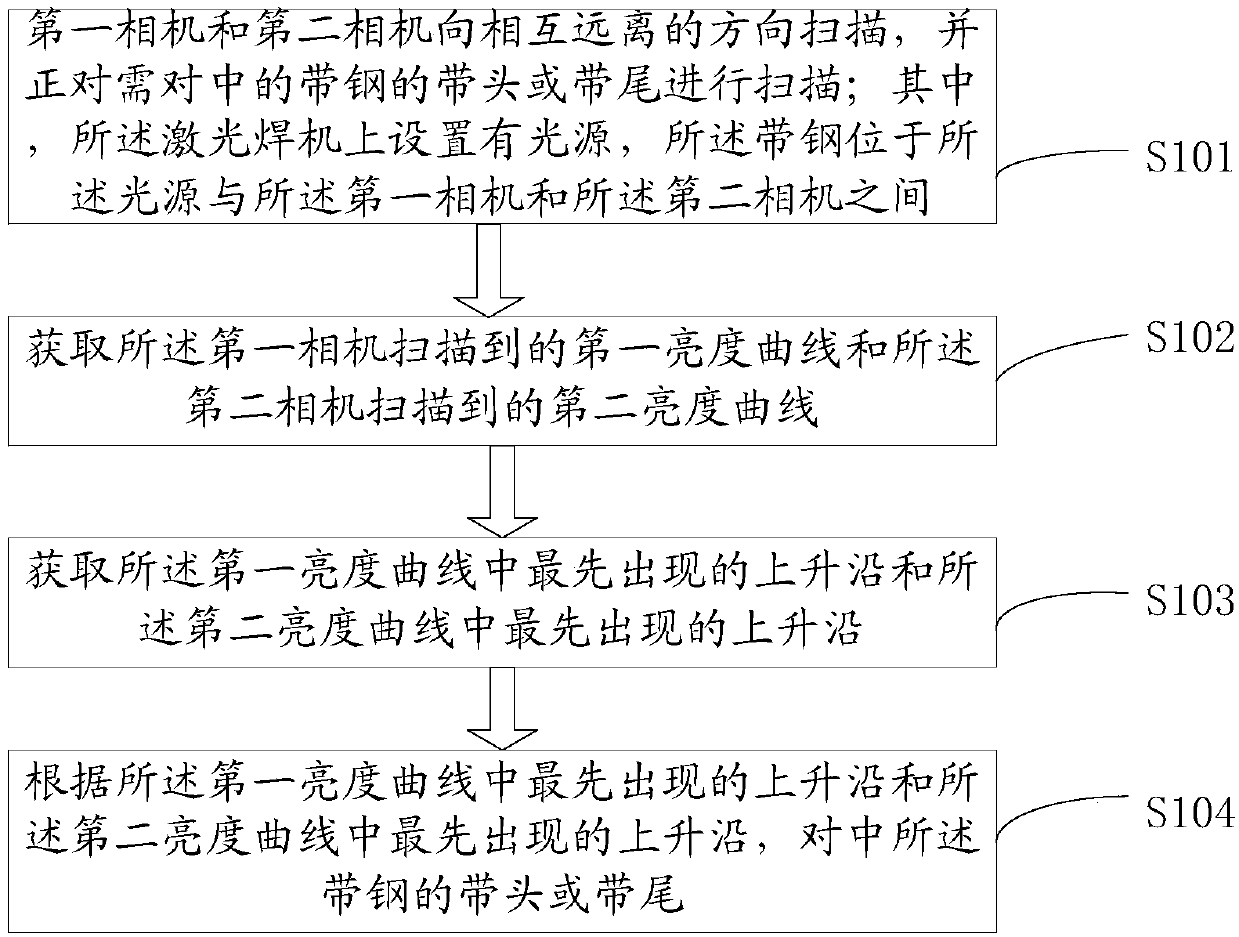

[0043] In this embodiment, a control method of a laser welding machine with a head and a tail centering camera is provided, such as figure 1 Shown include:

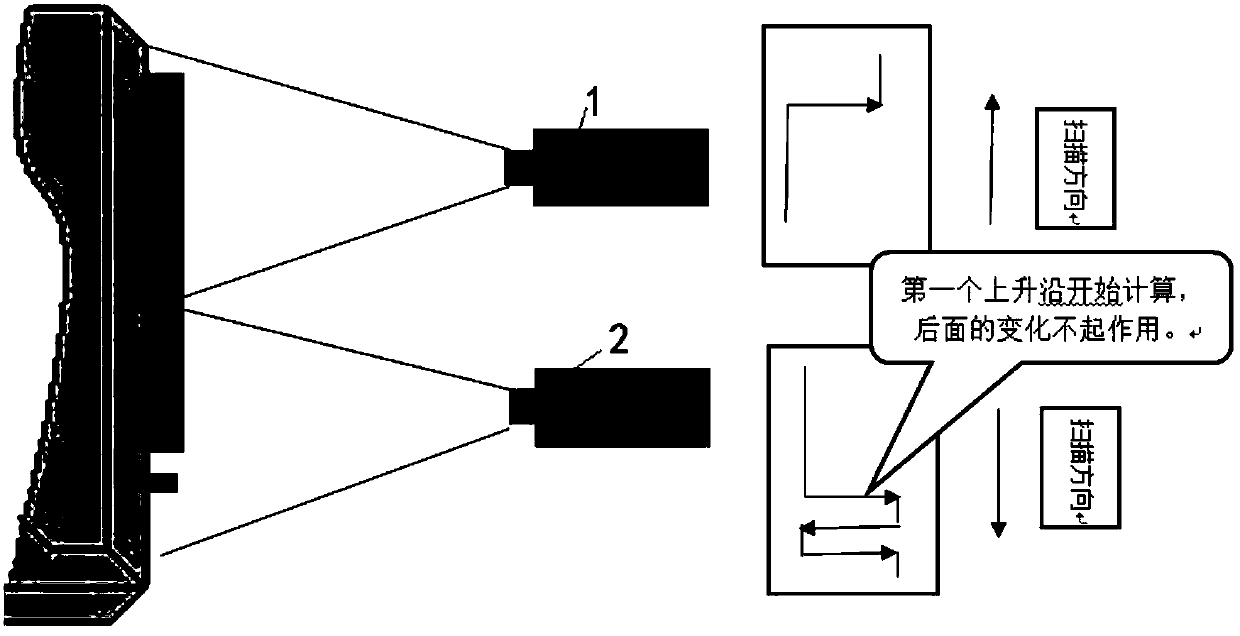

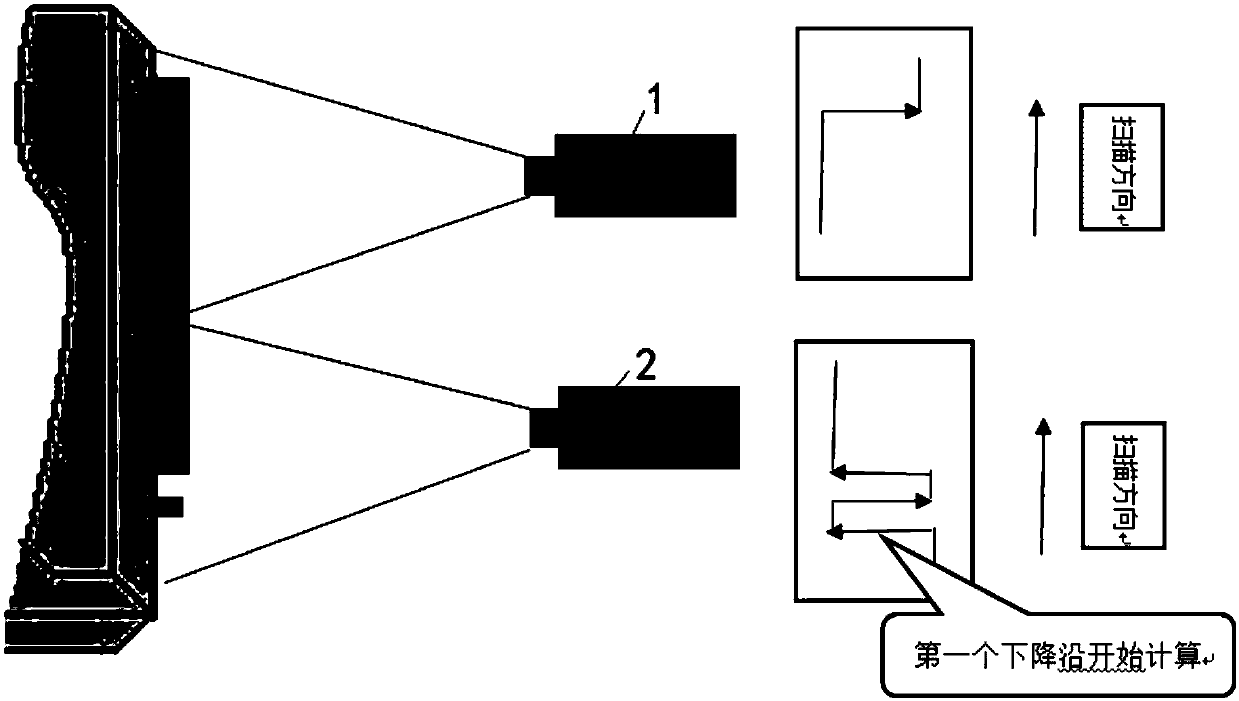

[0044] Step S101, the first camera and the second camera scan in a direction away from each other, and scan the head or tail of the steel strip to be aligned; wherein, the laser welding machine is provided with a light source, and the steel strip between the light source and the first and second cameras;

[0045] Step S102, acquiring a first brightness curve scanned by the first camera and a second brightness curve scanned by the second camera;

[0046] Step S103, acquiring the first rising edge in the first brightness curve and the first rising edge in the second brightness curve;

[0047] Step S104, centering the strip head or strip tail according to the first rising edge in the first brightness curve and the first rising edge in the second brightness curve.

[0048] It should be noted that a light source is provided o...

Embodiment 2

[0081] This embodiment provides a control device for a laser welding machine with a head and a tail centering camera, such as Figure 4 shown, including:

[0082] The scanning module 401 is used to control the first camera and the second camera to scan in a direction away from each other, and is scanning the head or tail of the steel strip to be centered; wherein, the laser welder is provided with a light source, the strip is located between the light source and the first and second cameras;

[0083] A curve acquiring module 402, configured to acquire a first brightness curve scanned by the first camera and a second brightness curve scanned by the second camera;

[0084] A rising edge acquisition module 403, configured to acquire the first rising edge in the first brightness curve and the first rising edge in the second brightness curve;

[0085] The centering module 404 is configured to center the strip head or strip tail according to the first rising edge in the first brig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com