China-hemp blended surface layer material for hygienic products and preparation method of material

A technology for surface materials and hygiene products, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of dryness, air permeability and skin-friendly properties, and achieve the effect of soft and comfortable fabrics and good natural antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

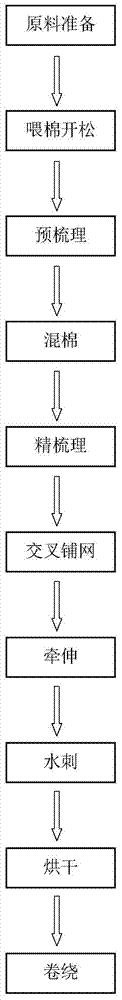

[0032] The method for preparing the hemp blended surface layer material for sanitary products described in the present embodiment comprises the following steps:

[0033] The hemp fiber and raw cotton fiber are sequentially fed, rough opened, blended, pre-carded, blended, combed, laid, drafted, spunlace, and dried to obtain the hemp blended surface for sanitary products. layer material.

[0034] (1) Raw material preparation: select hemp fiber and raw cotton fiber, the average length of hemp fiber is 32mm, the average fineness is 2.4D, the average length of raw cotton fiber is 38mm, and the average fineness is 1.4D. The initial quantitative is scheduled to be 32g / m 2 , the mass percentage of hemp fiber is 30%, and the mass percentage of raw cotton fiber is 70%.

[0035] (2) Cotton feeding and rough opening: the hemp fiber and raw cotton fiber are sent to the rough opener by the automatic cotton feeding machine for opening, so that the fiber blocks and large cotton clusters are...

Embodiment 2

[0066] The method for preparing the hemp blended surface layer material for sanitary products described in the present embodiment comprises the following steps:

[0067] The hemp fiber and Lyocell fiber are sequentially fed, coarsely opened, blended, pre-carded, blended, combed, laid, drafted, spunlace, and dried to obtain the hemp blended surface for sanitary products. layer material.

[0068] (1) Raw material preparation: use hemp fiber and Lyocell fiber, the average length of hemp fiber is 32mm, the average fineness is 2.4D, the average length of Lyocell fiber is 38mm, and the average fineness is 1.5D. The initial quantitative is scheduled to be 25g / m 2 , the mass percentage of hemp fiber is 50%, and the mass percentage of raw cotton fiber is 50%.

[0069] (2) Cotton feeding and rough opening: the automatic cotton feeding machine sends the hemp fiber and Lyocell fiber to the rough opener for opening, so that the fiber blocks are separated, mixed and fully opened. The coa...

Embodiment 3

[0100] The method for preparing the hemp blended surface layer material for sanitary products described in the present embodiment comprises the following steps:

[0101] The hemp fiber and viscose fiber are sequentially fed, coarsely opened, blended, pre-carded, blended, combed, laid, drafted, spunlace, and dried to obtain the hemp blended fabric for sanitary products. Surface material.

[0102] (1) Raw material preparation: use hemp fiber and viscose fiber, the average length of hemp fiber is 32mm, the average fineness is 2.4D, the average length of viscose fiber is 38mm, and the average fineness is 1.4D. The initial quantitative is scheduled to be 40g / m 2 , the mass percentage of hemp fiber is 40%, and the mass percentage of viscose fiber is 60%.

[0103] (2) Cotton feeding and rough opening: the hemp fiber and viscose fiber are sent to the rough opener by the automatic cotton feeding machine for opening, so that the fiber blocks and large cotton balls are separated, mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com