Circular stockyard

A circular material yard and material storage technology, which is applied in the field of bulk material storage and transportation facilities, can solve the problems of rising civil construction costs, thick longitudinal walls, and large investment in equipment costs, so as to achieve low civil construction costs and reduce construction costs. Length, the effect of reducing equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below.

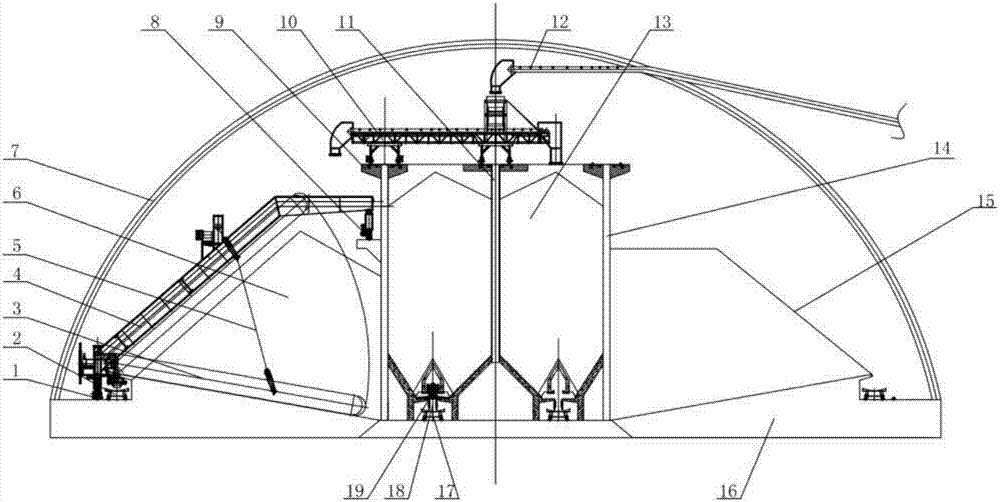

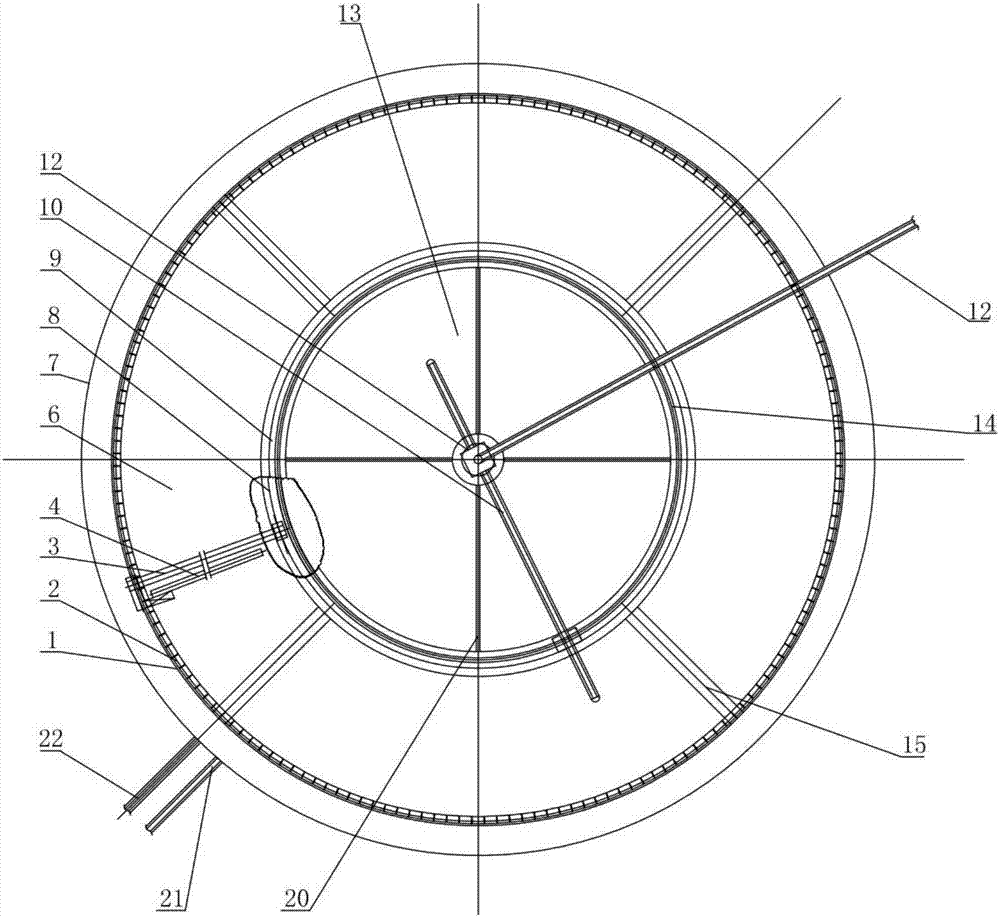

[0026] The reference signs in the accompanying drawings of the specification include:

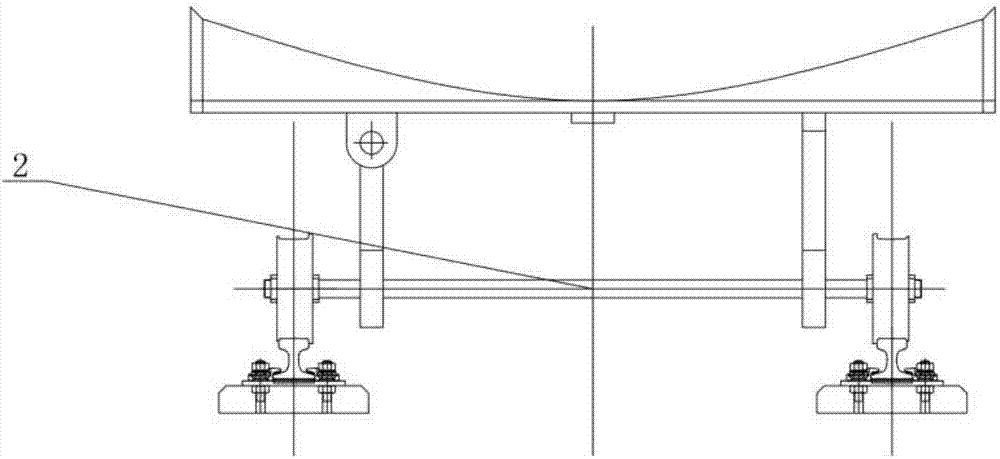

[0027] The second circular track 1, the storage grid conveyor 2, the storage grid reclaimer 3, the gantry frame 4, the cable hoist or hydraulic telescopic mechanism 5, the storage grid 6, the closed storage shed 7, the second A circular track 8, an input conveying system conforming platform 9, a feed stacker 10, a lighting and ventilation channel 11, a feed conveyor 12, a storage bin 13, an annular retaining wall 14, a radial retaining wall 15, and a storage load Bottom plate 16, storage bin conveyor 17, storage bin material output baffle 18, storage bin reclaimer 19, storage bin partition wall 20, storage bin discharge conveyor 21, storage bin discharge conveyor twenty two.

[0028] like figure 1 , figure 2 The circular stock yard shown includes a material storage base plate 16 on which a closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com