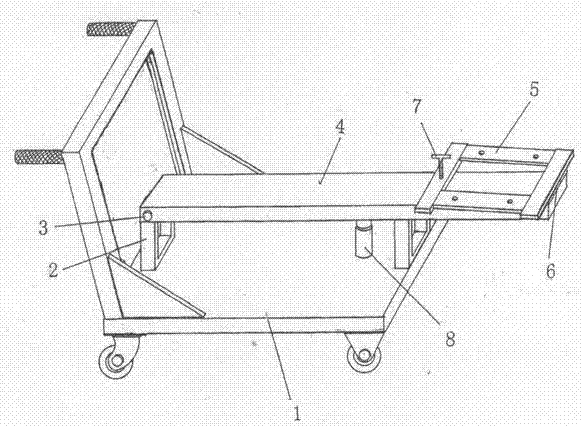

Cart used for assembly and disassembly of heat-setting motor in textile production

A trolley and hot air technology, which is applied in the direction of trolleys, multi-axis trolleys, motor vehicles, etc., can solve the problems of inconvenient lifting and transportation, and achieve the effects of solving inconvenience of lifting and transportation, improving safety maintenance equipment, and facilitating disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] figure 1 As shown: the trolley used for the disassembly and assembly of the hot air motor in the textile industry is installed with a lifting support plate 4 on the top of the flat car body 1 through the support 2 and the pin shaft 3. The front end of the lifting support plate 4 is connected with the motor fixing plate 5 through the hinge 6. An angle adjustment screw rod 7 is arranged on the rear side of the motor fixing plate 5, and a hydraulic cylinder 8 is installed below the lifting support plate 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com