Ultrasonic rail flaw-detection trolley system based on deep learning and control method thereof

A deep learning and ultrasonic technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, railway inspection vehicles, etc. There are many factors and other problems to achieve the effect of improving detection accuracy, high-accuracy detection, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

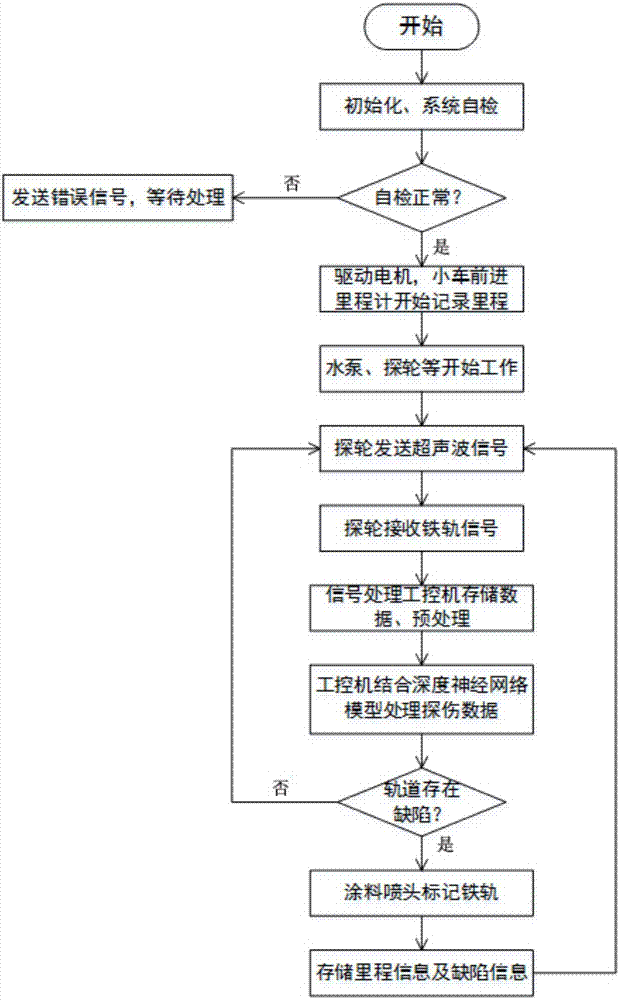

[0032] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

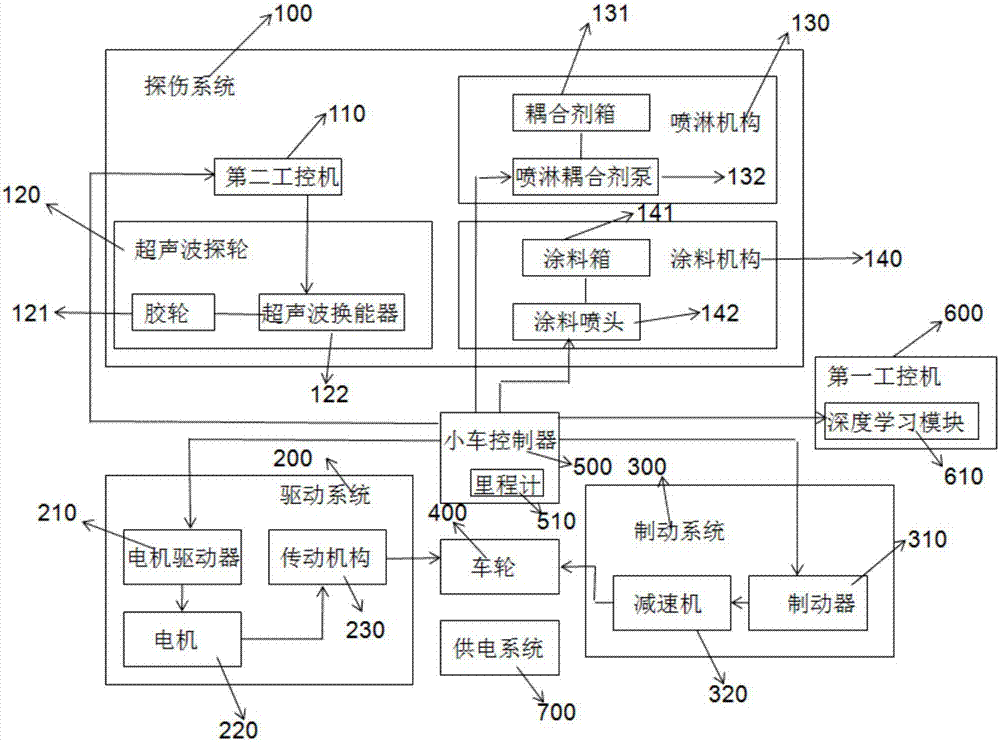

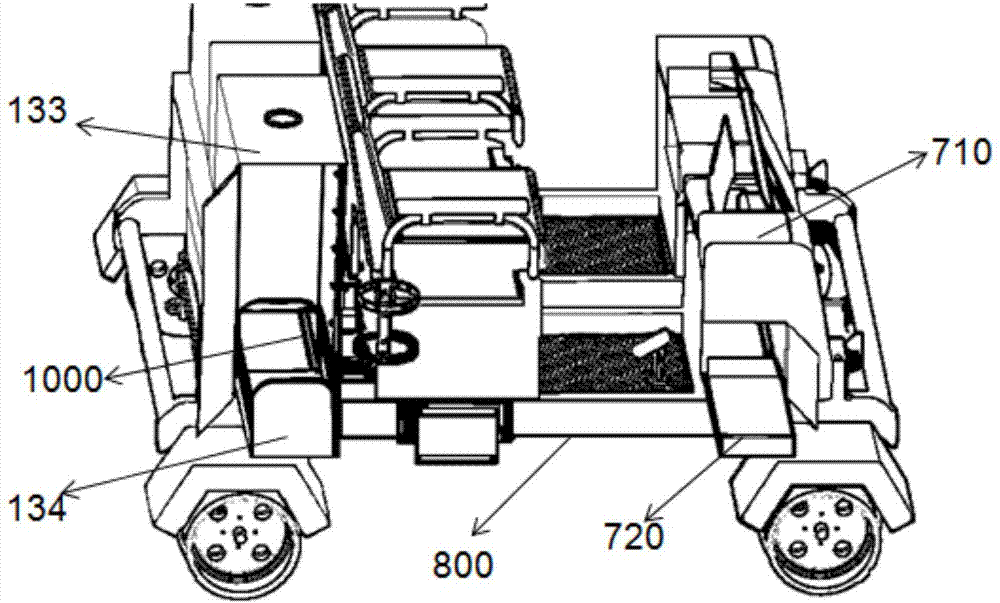

[0033] Such as figure 1 As shown, the present invention provides a deep learning-based ultrasonic rail flaw detection car system, including a flaw detection system 100, a drive system 200, a brake system 300, a wheel 400 connected to the drive system 200 and the brake system 300, and a car controller 500. The first industrial computer 600 and the power supply system 700 for supplying power to each part of the trolley system;

[0034] The flaw detection system 100 includes a second industrial computer 110, an ultrasonic probe wheel 120 connected to the second industrial computer 110, a spray mechanism 130, and a paint mechanism 140; the ultrasonic probe wheel 120 includes a rubber wheel 121 filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com