Electric control digital end fracturing sliding sleeve

A technology for fracturing sliding sleeves and sliding sleeves, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problem of affecting the normal production of shale gas, high risk of sliding sleeve opening operations, and inability to determine shale gas wells To achieve the effect of being suitable for large-scale promotion and application, avoiding uncertainty and improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

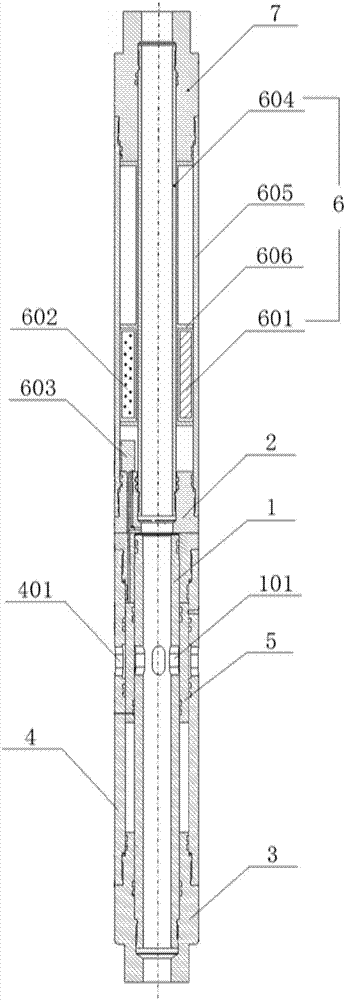

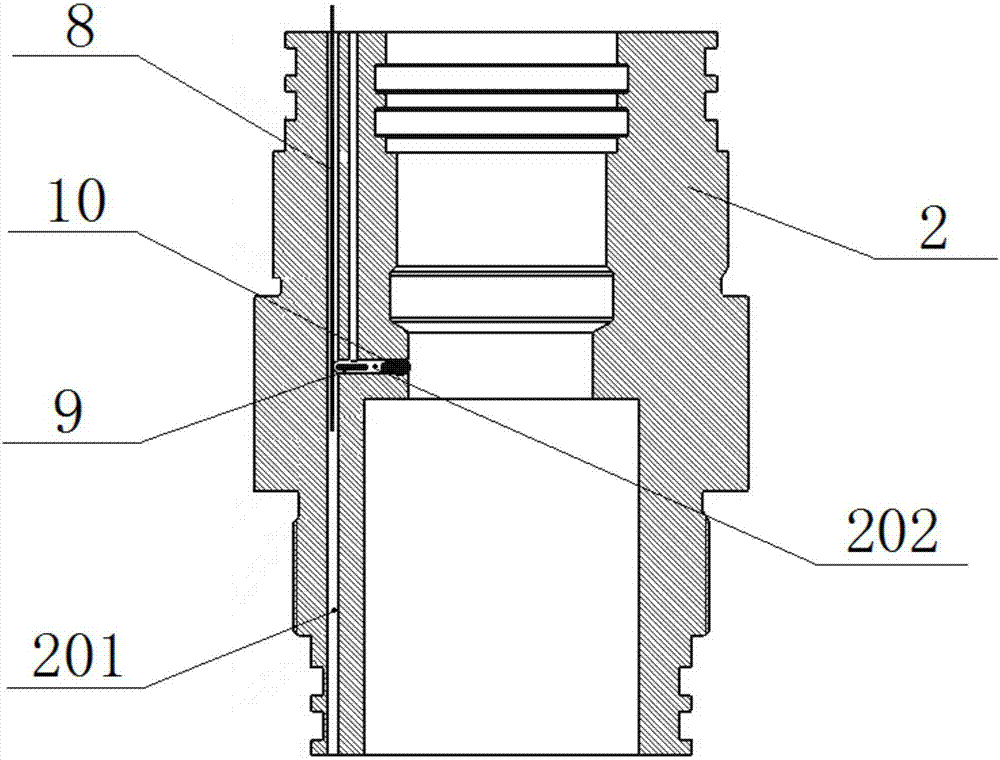

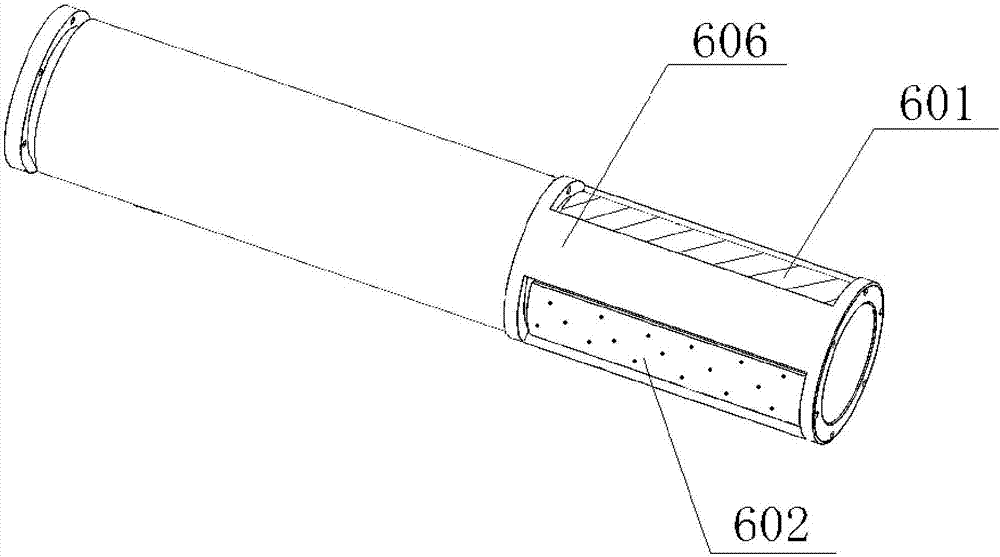

[0060] The embodiment of the present invention provides an electronically controlled toe end fracturing sleeve, as attached figure 1 And attached figure 2 As shown, the fracturing sliding sleeve includes: the sliding sleeve inner cylinder 1, the two ends of which are respectively connected with the conversion joint 2 and the lower joint 3, and the first sandblasting hole 101 is arranged on the cylinder wall; the sliding sleeve outer cylinder 4 is set on the sliding sleeve On the outer side of the sleeve inner cylinder 1, the two ends are respectively connected with the conversion joint 2 and the lower joint 3, and the second sandblasting hole 401 corresponding to the position of the first sandblasting hole 101 is arranged on the cylinder wall; the sliding sleeve 5, through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com