Solving method for transverse cracking of J55 grade microalloy steel angle

A technology of micro-alloy steel and solution, which is applied in the field of continuous casting slab quality control, to achieve the effects of suppressing the generation of micro-cracks, reducing the generation of bending and straightening cracks, and avoiding the generation of micro-cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: The present invention provides a solution to the transverse cracks at the billet corners of J55 grade steel. The following is a complete description of the implementation cases. The specific methods are as follows:

[0032]During the production of J55 grade steel with a section of 1243×230mm in a steel factory, a large number of transverse cracks appeared at the corners of the billet. The composition range of the molten steel is shown in Attached Table 1:

[0033] Table 1

[0034]

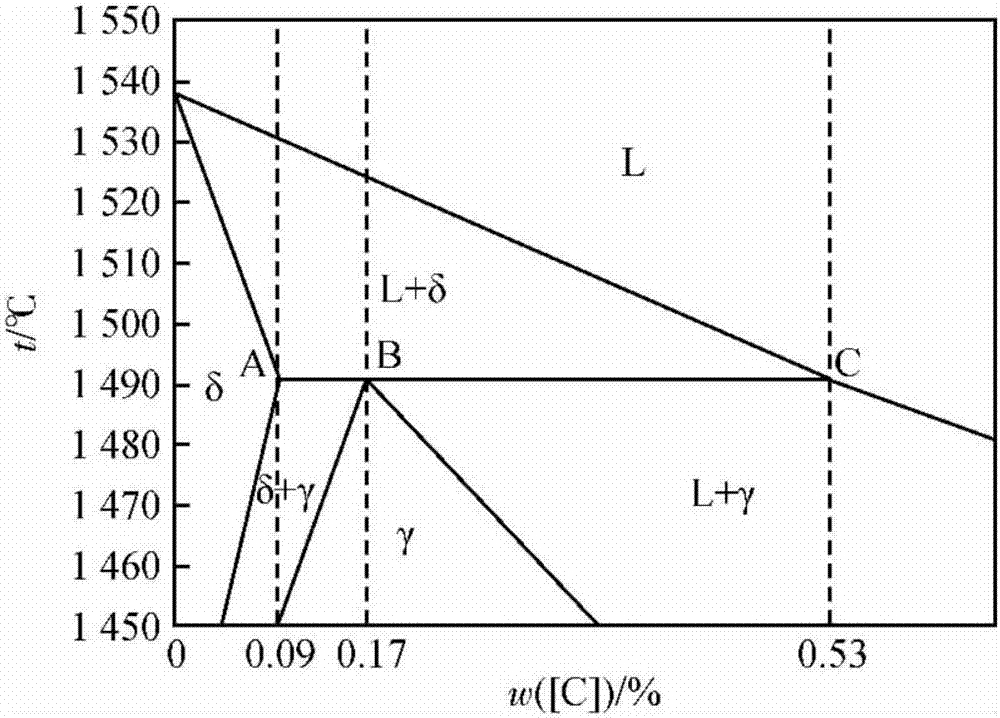

[0035] After adopting the present invention, using the peritectic feature point prediction formula (2) to compare with the actual composition, it can be concluded that the J55 steel with this composition belongs to the peritectic steel. Combining formulas (1)(3)(5), it can be seen that the comprehensive product of the basic content of alloying elements such as C, Mn, Si, Al, Cr and their contribution coefficients to the movement of the peritectic point is relatively large, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com