Eucommia ulmoides gum self-repairing gel preparation method

A technology of eucommia glue and self-healing, which is applied in the field of preparation of eucommia glue self-healing gel to achieve the effects of easy availability of raw materials, mature polymerization process and high repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

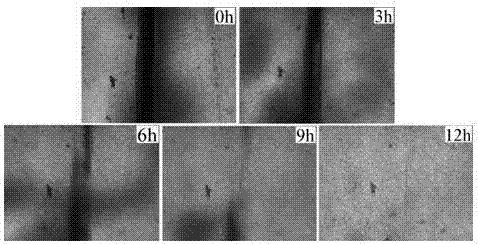

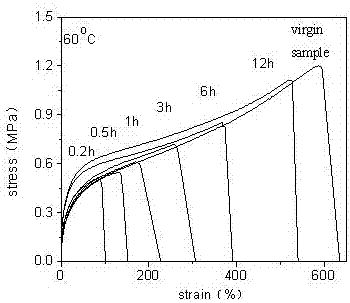

Image

Examples

Embodiment 1

[0020] Dissolve 5 g of Eucommia gum in 100 ml of toluene, raise the temperature to 70°C until completely dissolved, add 0.75 g of initiator dibenzoyl peroxide, and simultaneously add 13.4 ml of butyl methacrylate monomer dropwise. After 1 hour, add 0.25 g of initiator dibenzoyl peroxide. When phase separation occurs in the system, the reaction is continued for 1 hour. The product is washed with ethanol and air-dried, then vacuum-dried at 40°C for 24 hours.

Embodiment 2

[0022] Dissolve 10g of Eucommia gum in 150ml of petroleum ether 90-120, raise the temperature to 75°C until completely dissolved, add 0.75g of initiator dicumyl peroxide, and dropwise add 32.4ml of ethyl methacrylate monomer. When phase separation occurred in the system, the reaction was continued for 3 h, and the product was washed with ethanol and air-dried, then vacuum-dried at 40 °C for 24 h. Example 3

Embodiment 3

[0023] Dissolve 10g of Eucommia gum in 140ml of petroleum ether 60-90, raise the temperature to 65°C until completely dissolved, add 1g of initiator tert-butyl peroxyvaleric acid, and dropwise add 26.6ml of butyl methacrylate monomer. After 1 hour, add 0.5 g of initiator, and continue to react for 5 hours when phase separation occurs in the system. The product is washed with ethanol and air-dried, then vacuum-dried at 40°C for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com