Power assisting device of steering system

A technology of a power assist device and a steering system, which is applied to steering mechanisms, mechanical steering gears, electric steering mechanisms, etc., can solve the problems of poor consistency of no-load rotational torque of worm gears, vibration noise, and machining deviations of worm gears and worms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

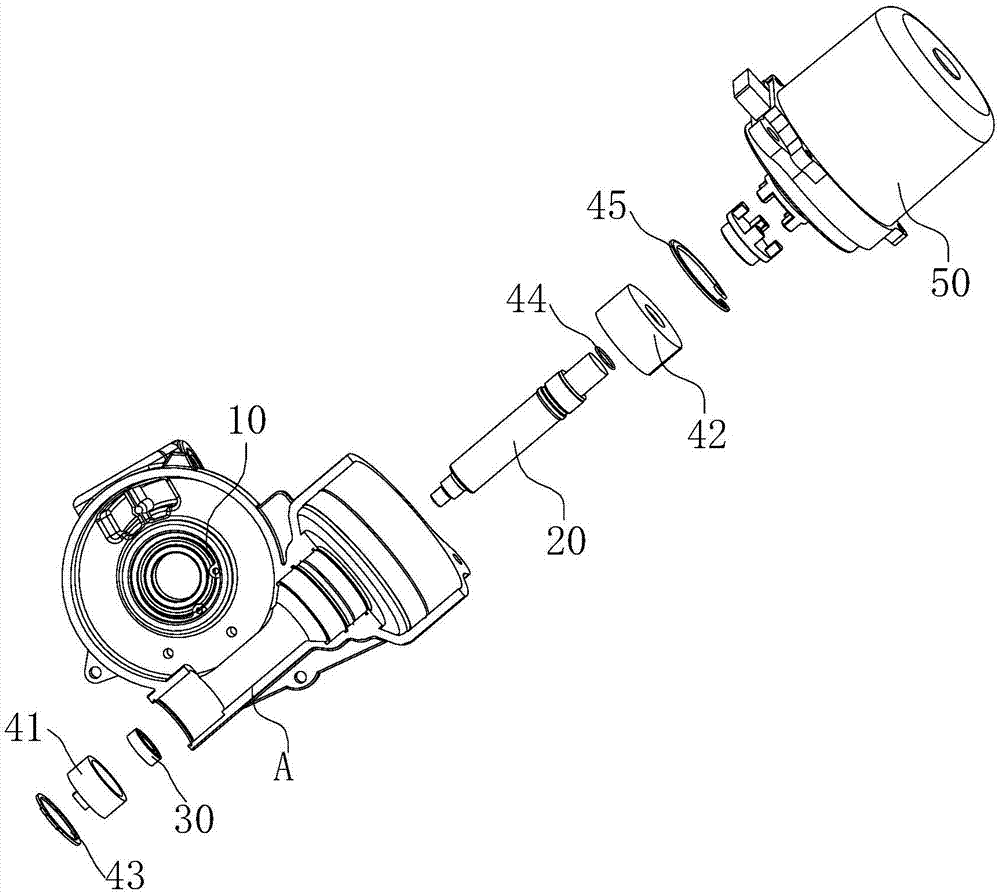

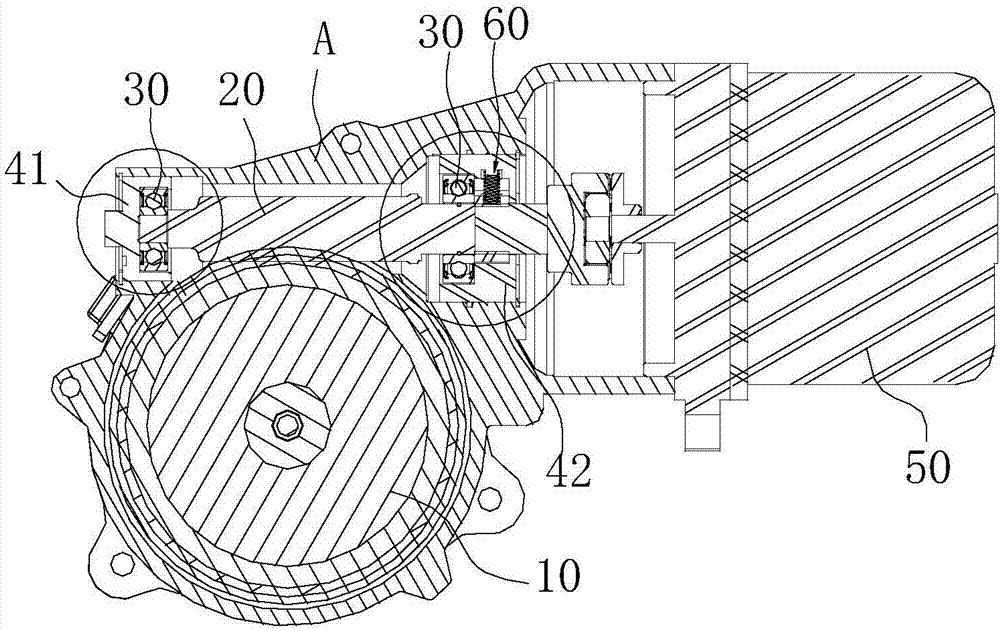

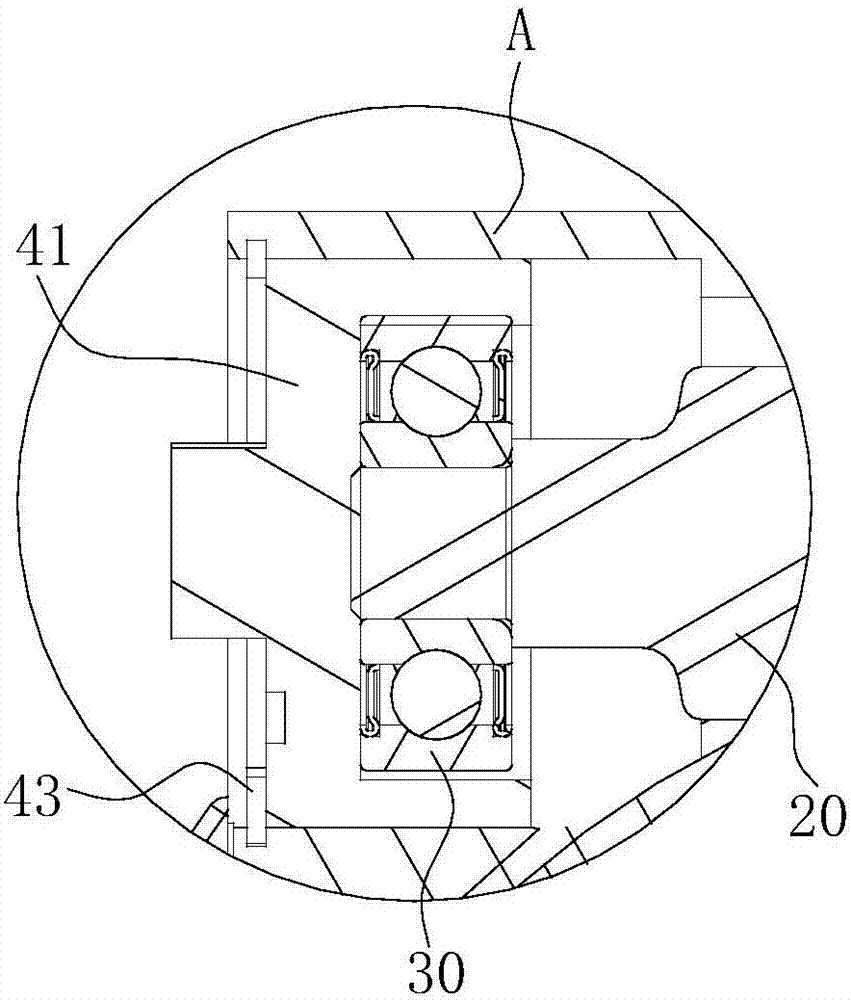

[0012] Combine below Figure 1-Figure 7 The present invention is discussed in further detail.

[0013] A power assist device for a steering system, comprising a worm gear 10 and a worm 20 meshing with each other, one end of the worm 20 is coaxially connected with the output shaft of the power assist motor 50, and the bearing 30 at the other end of the worm 20 is connected to the reducer housing A A first bearing seat 41 is disposed between them, and the bearing installation hole core of the first bearing seat 41 is eccentrically set with the outer circle center of the first bearing seat 41 . Rotating the first bearing seat 41 drives the worm 20 to press the worm wheel 10 . Since the inner cavity of the first bearing seat 41 is eccentrically arranged, when there is a machining tolerance, installation tolerance or wear gap between the worm wheel and the worm 10, 20, the first bearing seat 41 is rotated to drive the worm 20 closer to or away from the worm wheel 10, Adjust the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com