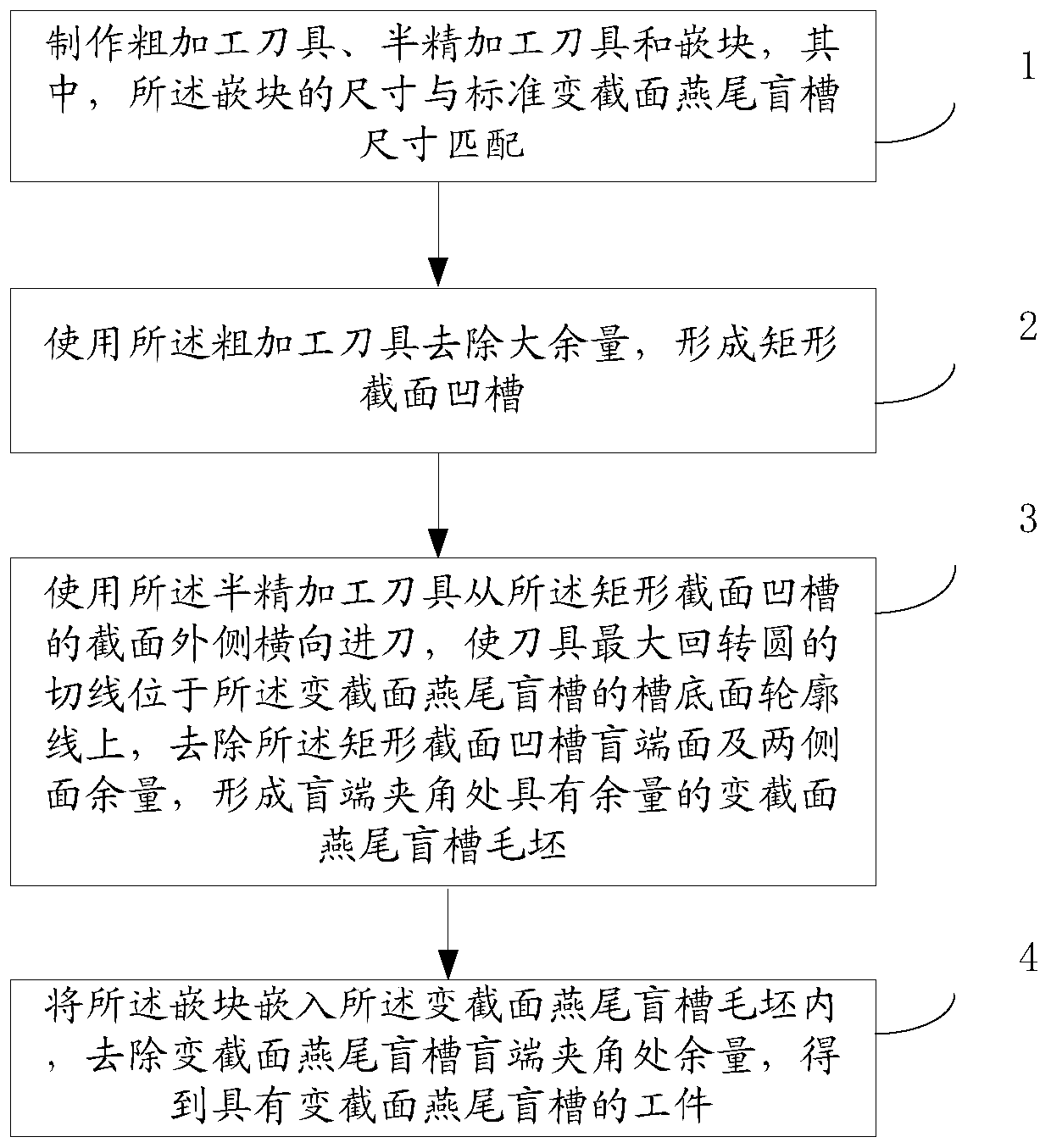

A kind of composite material variable-section dovetail blind groove machining method

A composite material and processing method technology, which is applied in the field of composite material variable cross-section dovetail blind groove processing, can solve the problems that cannot meet the processing requirements of composite materials, reduce the quality of the processed surface, and reduce the durability of the tool, so as to prevent chipping and ensure processing quality, effect of reduced feed rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0053] The workpiece to be processed is a resin-based glass fiber composite material formed by a molding process. The variable cross-section dovetail blind groove to be processed is located on the inner arc surface of the blank. The specific processing steps are as follows:

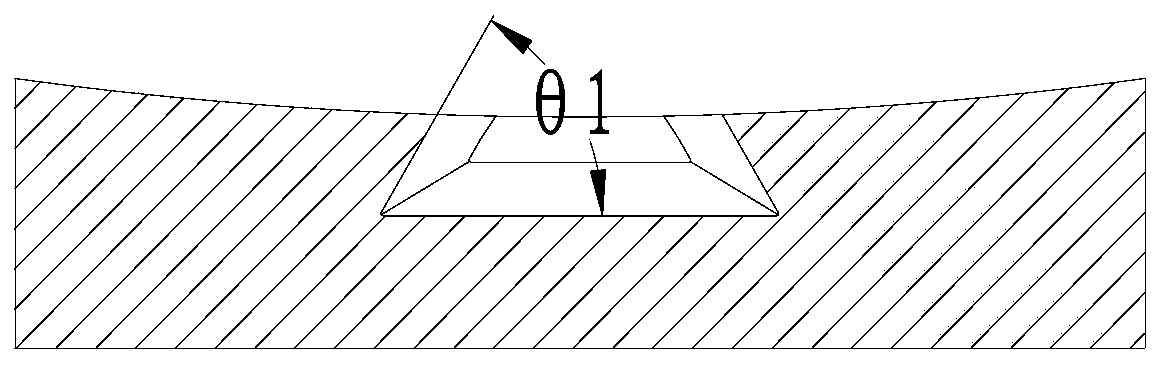

[0054] S1: Measure the size of the variable-section dovetail blind groove, the minimum distance between the dovetail edge of the dovetail blind groove L1=15mm, the minimum distance between the root of the dovetail blind groove L2=19.5mm, the angle between the inner surface and the bottom surface of the dovetail blind groove θ1=60°, the bottom surface and the bottom surface of the workpiece The included angle θ2=5°, the included angle θ3=8.25° between the dovetail side and the center line;

[0055] S2: Customize the tool according to the size recorded in step S1: 1) Customize the electroplated diamond end mill according to the size L1, and its diameter D1=10mm; 2) Customize the electroplated diamond dovetai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com