Internally-installed pneumatic rinsing tank for fasteners

A technology for washing tanks and fasteners, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of poor washing effect and liquid overflow, and achieve good washing effect and fast washing speed Fast and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and specific embodiments.

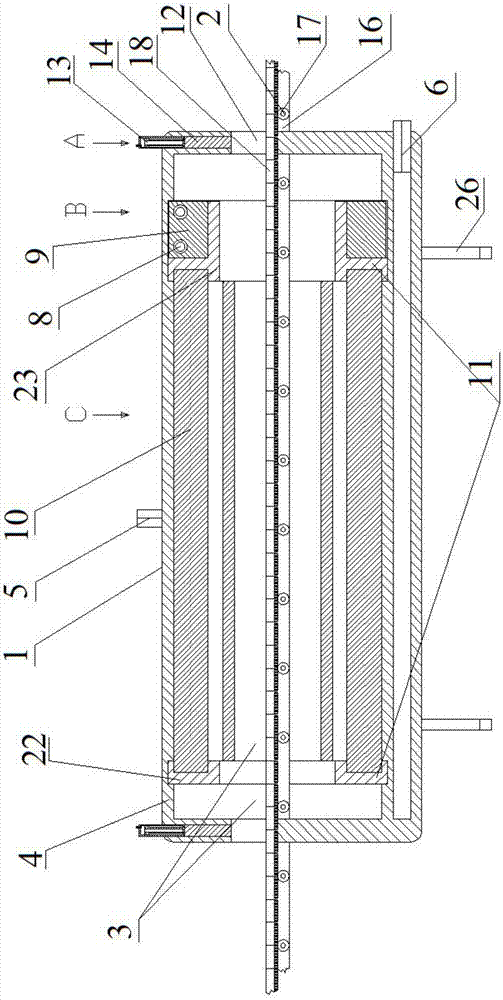

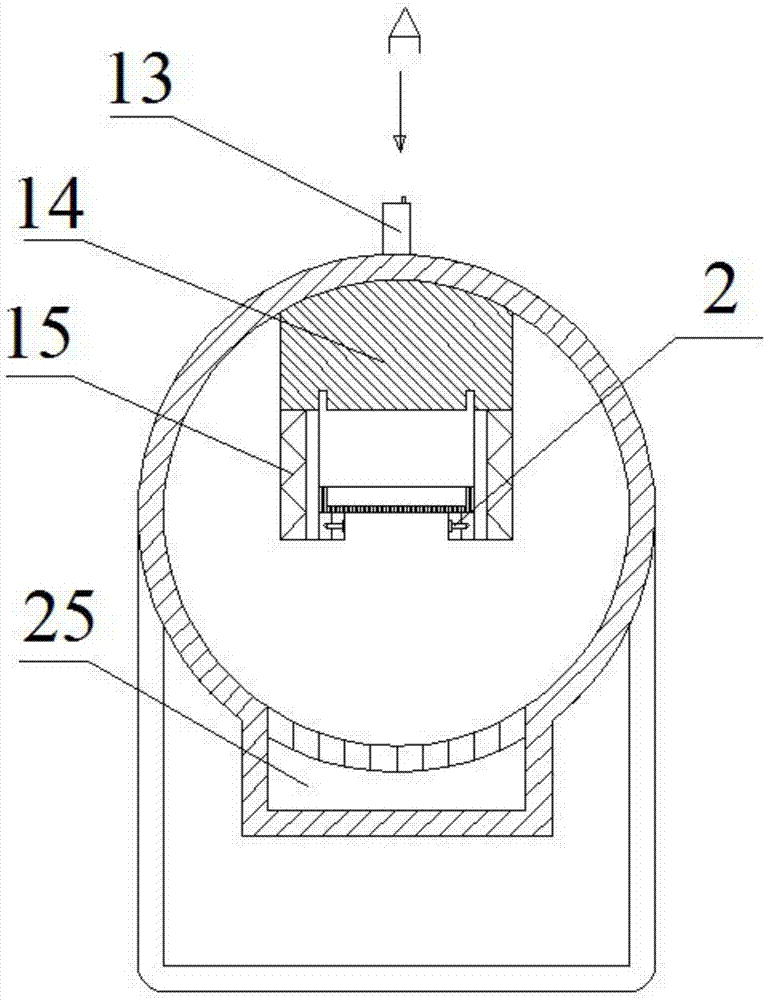

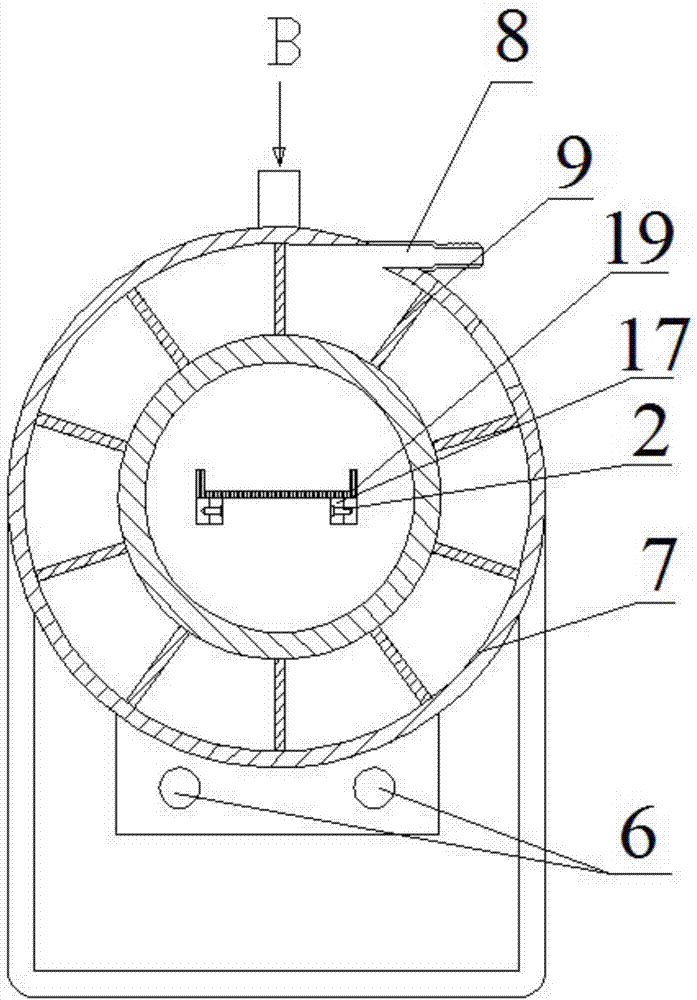

[0018] The present invention provides a washing tank with built-in pneumatic fasteners, comprising a washing tank 1 with a liquid storage cavity 3 inside and a conveying device for transporting fasteners 2 to be washed, characterized in that the washing tank 1 includes a housing 4 , A pneumatic drive device located inside the housing 4, a sealing device located at both ends of the housing 4 and intermittently sealing the housing 4, and a rolling device located in the housing 4, the upper end, the lower end and the interior of the housing 4 are respectively A water inlet 5, a water outlet 6 and a liquid storage cavity 3 are provided. The housing 7 of the pneumatic drive device is a part of the housing 4. The pneumatic drive device includes an air inlet 8 and a plurality of groups of pneumatic blades 9. The device includes a plurality of sets of water turning bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com