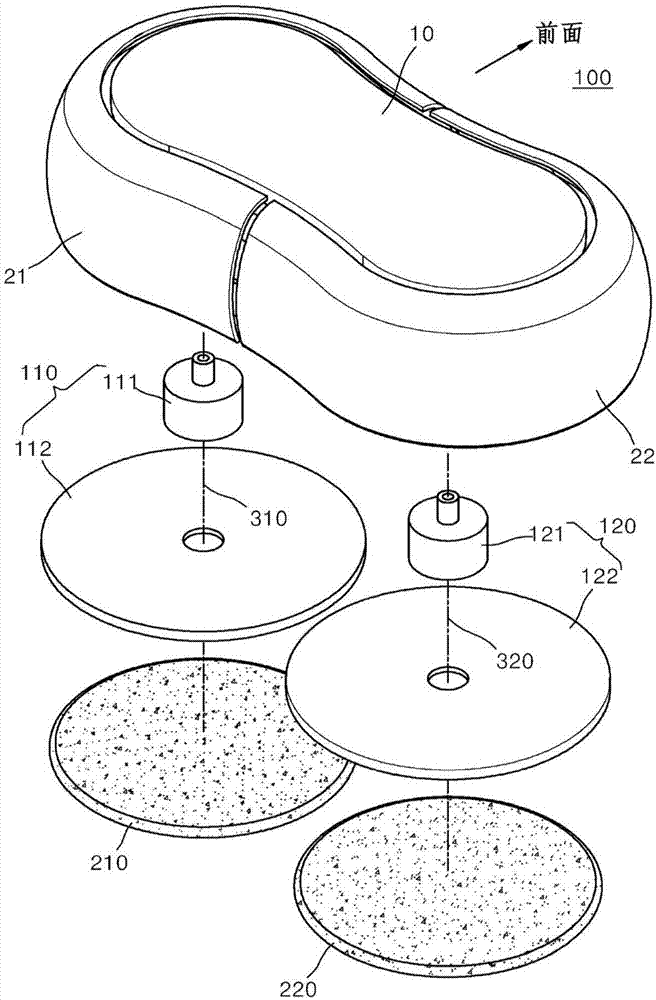

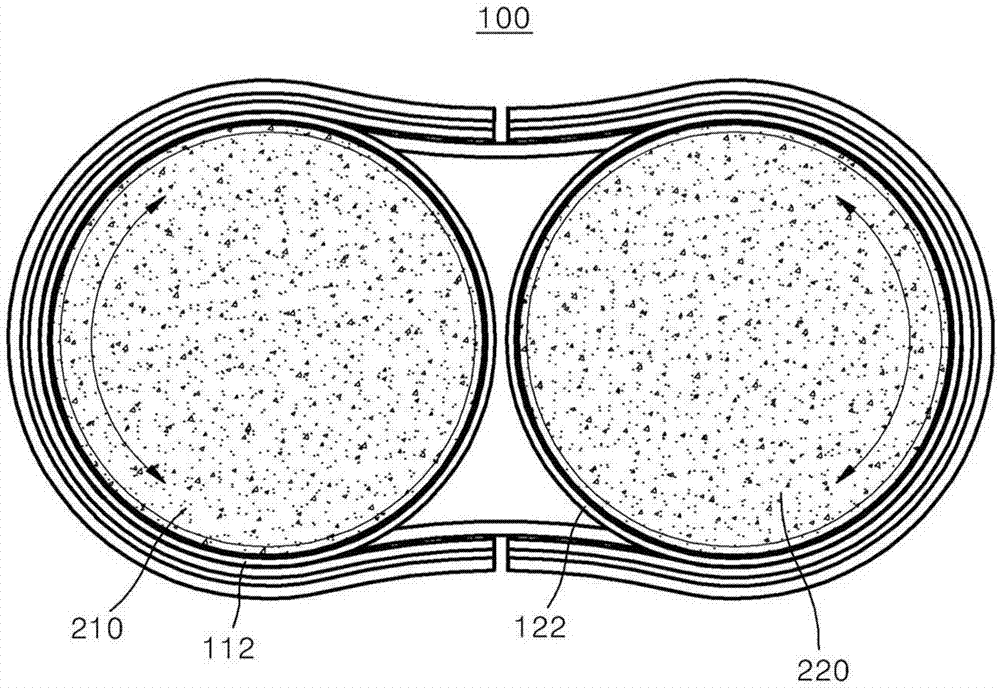

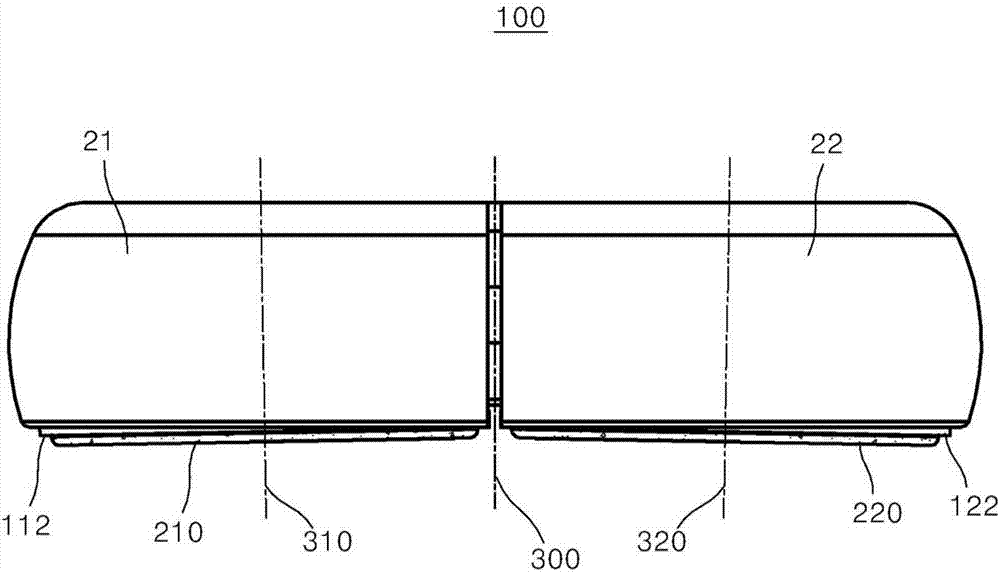

Robotic cleaner and control method therefor

A cleaning robot and control method technology, applied in the directions of robots, cleaning action control, cleaning machinery, etc., can solve the problems of increased battery consumption, low foreign object removal efficiency, inability to remove foreign objects or stubborn stains, etc., to save manufacturing costs, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following content is only to illustrate the principles of the present invention. Therefore, although not explicitly described or illustrated in this specification, those skilled in the art to which the present invention pertains can invent various devices embodying the principle of the present invention and included in the concept and scope of the present invention. In addition, all terms and examples mentioned in this specification are provided to clearly understand the concept of the present invention in principle, and therefore, it should be understood that the present invention is not limited to the specifically listed examples and states.

[0040] And, it should be understood that not only the principles, viewpoints, and embodiments of the present invention but also all detailed descriptions of specific embodiments include structural and functional equivalents of the matters described. And, it should be understood that the equivalents include all components inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com