A modular high-speed cutting experimental platform based on the Hopkinson pressure bar device

A Hopkinson pressure bar and experimental platform technology, applied in the field of metal cutting, can solve the problem of inconvenient tool replacement, and achieve the effect of convenient installation, convenient and quick use and installation, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

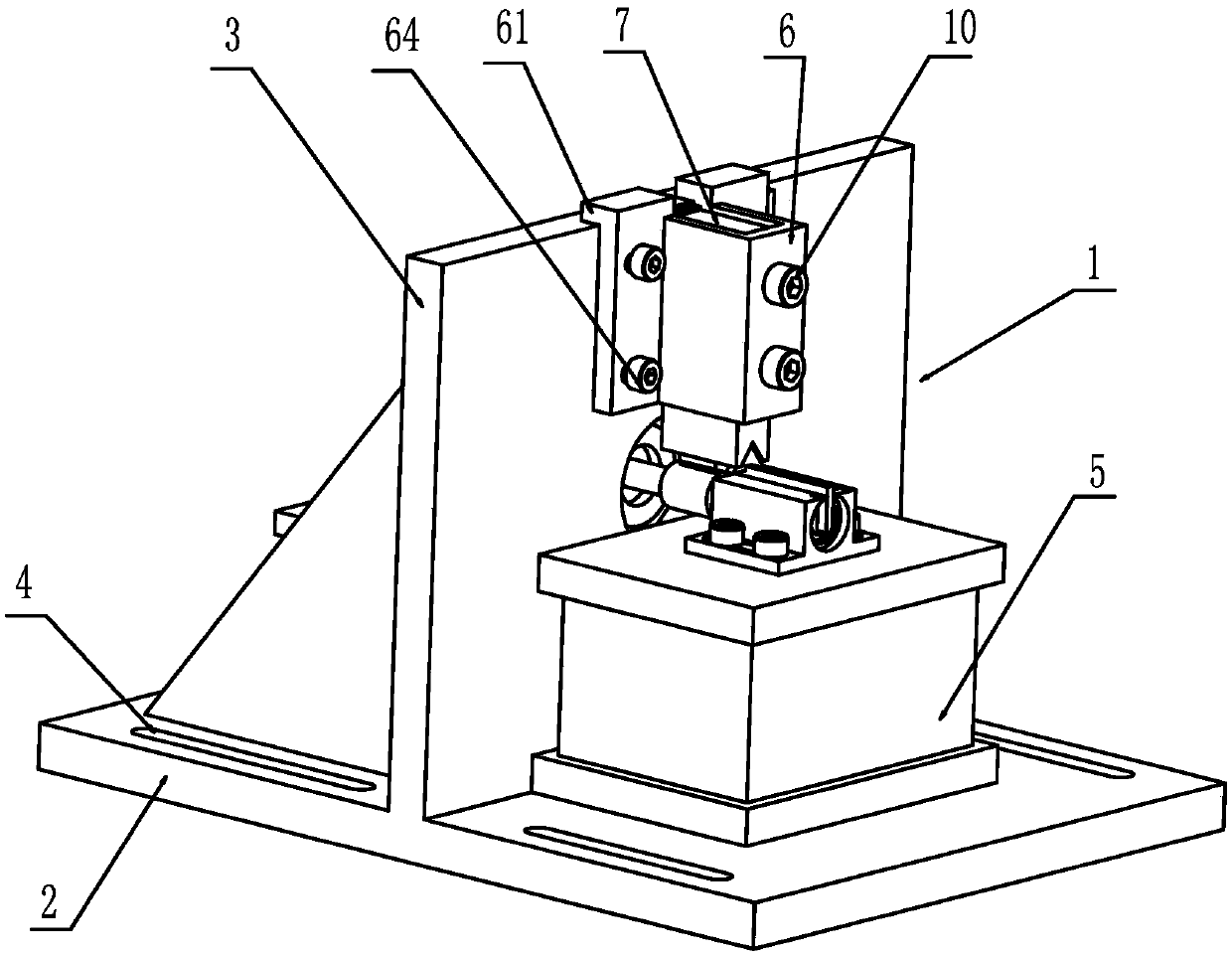

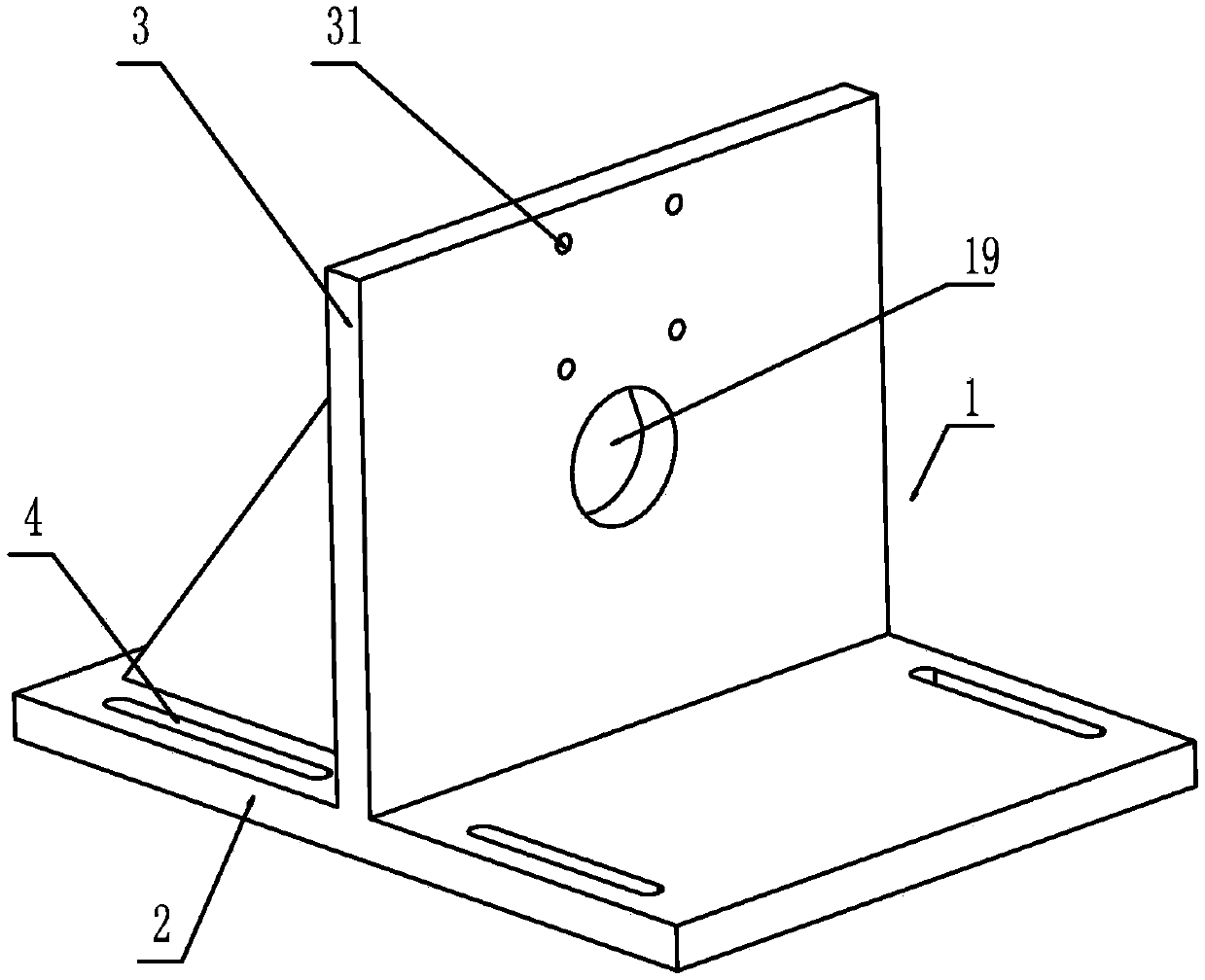

[0036] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

[0037] The present invention proposes a modular high-speed cutting experiment platform based on the Hopkinson pressure bar device, which includes a base support mechanism, a high-speed camera, a tool holder mechanism, a workpiece movement direction control mechanism, a base support mechanism or an energy-absorbing buffer mechanism, wherein, the base support mechanism is used to install and fix various components and related functional mechanisms, the high-speed camera is used to measure the instantaneous cutting speed, and the tool holder mechanism can realize , blade inclination angle and tool cutting function to adjust or change the tool, the workpiece movement direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com