CO2 flooding crude oil separation foamability testing device and method

A technology of foaming performance and testing device, which is applied in the research field of gas flooding technology, can solve the problems of gas-liquid separation without considering the fluid flow concentration, and achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

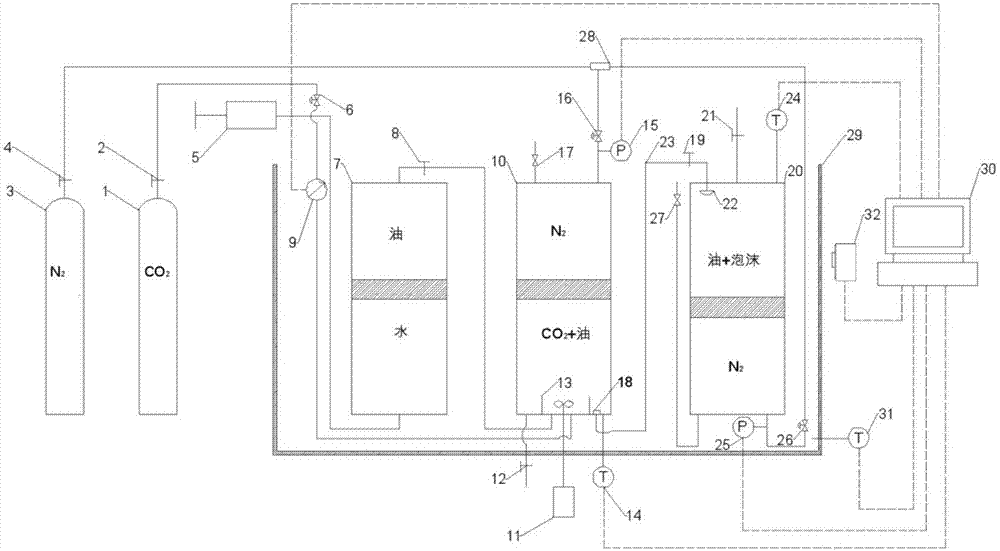

[0049] CO in this example 2 Foaming performance testing device for flooding crude oil separation such as figure 1 shown, the device includes: CO 2 Cylinder 1, CO 2 Cylinder valve 2, N 2 Cylinder 3, N 2 Gas cylinder valve 4, hand pump 5, pressure regulating valve 6, oil storage container 7, valve 8, gas flow meter 9, first piston pressure vessel 10, stirring device 11, vent valve 12, piston stopper 13, temperature Sensor 14, pressure sensor 15, pressure regulating valve 16, vent valve 17, vortex breaker 18, valve 19, second piston pressure vessel 20, vent valve 21, inlet baffle plate 22, analog pipeline 23, temperature sensor 24, pressure sensor 25. Pressure regulating valve 26, vent valve 27, tee 28, water bath device 29, controller 30, temperature sensor 31, video camera 32. The CO 2 After cylinder 1 is fitted with CO 2 Cylinder valve 2, CO 2 The gas enters the lower space of the first piston pressure vessel 10 through the gas flow meter 9 . N 2 N in cylinder 3 2 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Pressure endurance | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com