Deep eddy current testing device based on flux gate magnetometer and use method

A technology of eddy current detection and magnetometer, which is applied in the direction of measuring devices, material magnetic variables, and material analysis through electromagnetic means, which can solve the problems of unfavorable ultrasonic detection and the inability to use ultrasonic couplant, so as to improve the penetration depth and detection The effect of depth, low cost, high and low frequency sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

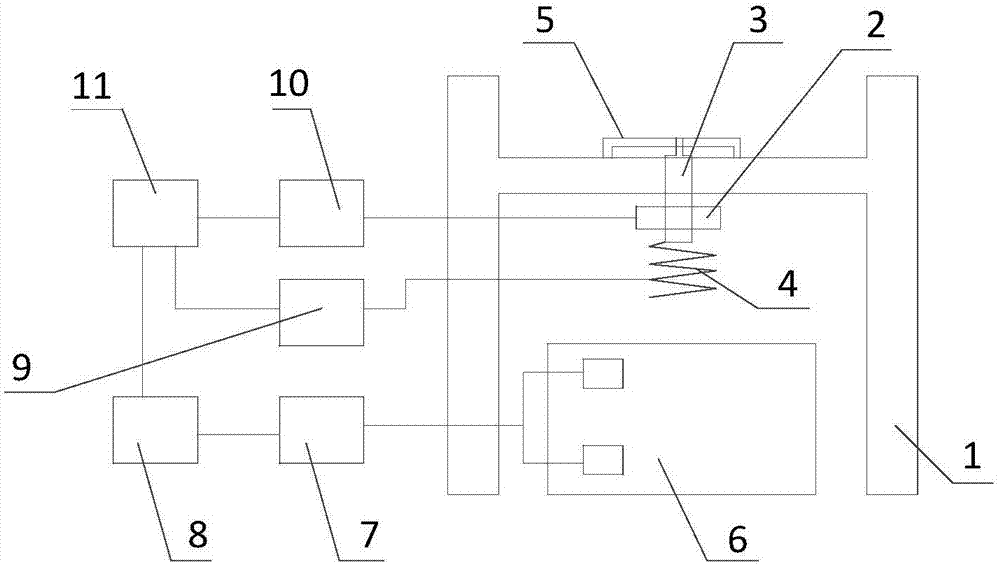

[0038] like figure 1 As shown, a deep eddy current detection device based on a fluxgate magnetometer includes a gantry-type measuring frame 1 constructed of 4040 aluminum profiles, and a fluxgate magnetometer probe 2 arranged in the middle of the crossbeam of the gantry-type measuring frame 1 , the measuring range of the fluxgate magnetometer probe 2 is greater than the geomagnetic field, the coil frame 3 arranged on the crossbeam of the gantry type measuring frame 1 is installed at the bottom of the coil frame 3 and facing the 400 below the fluxgate magnetometer probe 2 An excitation coil 4 with a turn diameter of 25 mm, which generates an ultra-low frequency magnetic field below 300 Hz, is set above the beam of the gantry-type measuring frame 1 to adjust the position of the coil frame 3. The fine-tuning screw 5 is set under the excitation coil 4 for placing The two-dimensional mobile platform 6 of the sample, there are two motors in the two-dimensional mobile platform 6, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com