Sounding device, acoustic module and electronic equipment equipped with the sounding device

A sounding device and electronic equipment technology, applied in the direction of frequency/direction characteristic devices, electrical components, sensor parts, etc., can solve the problems of damaging the acoustic performance of the sounding unit, affecting the service life of the sounding unit, and not being able to improve the low frequency band, so as to achieve the improvement Effects of low-frequency sensitivity, polarization suppression, and increase in equivalent volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

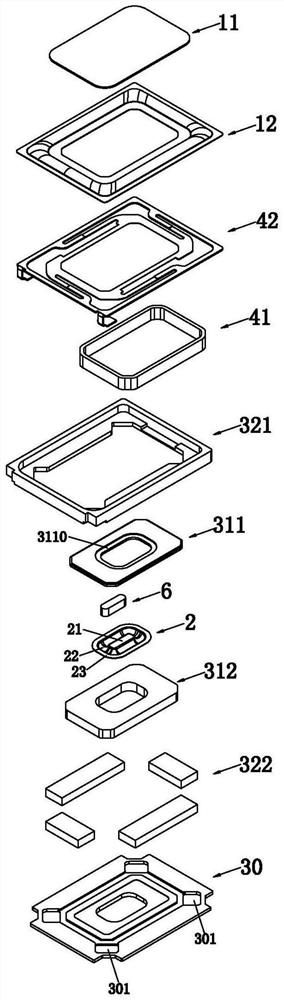

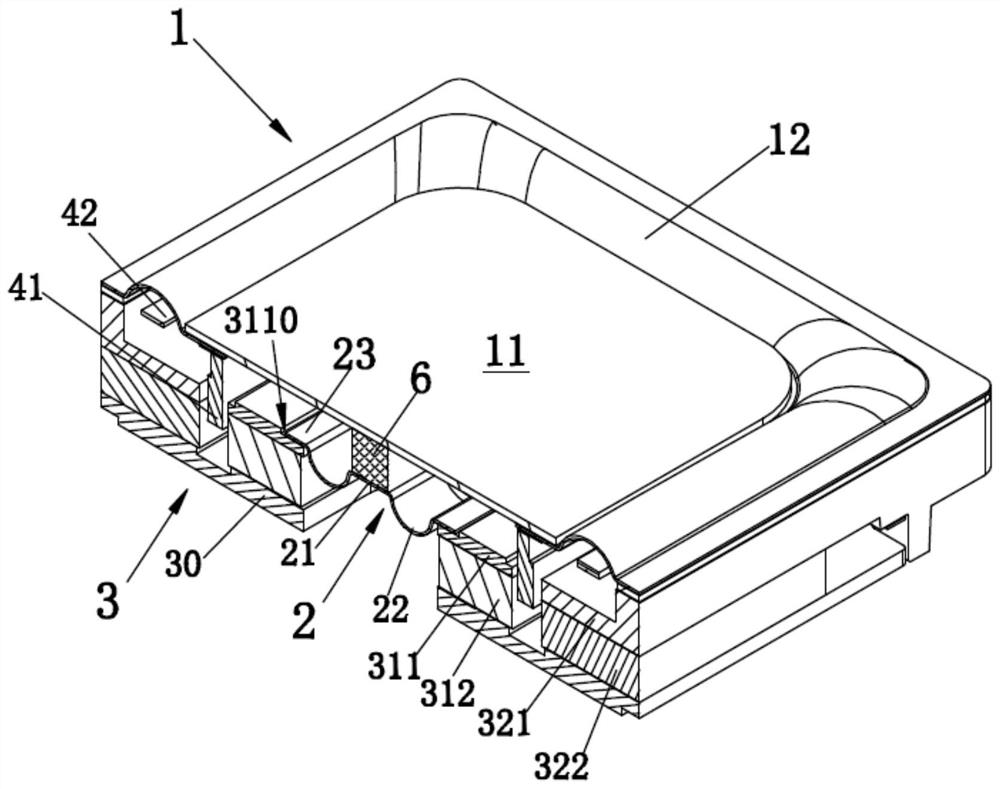

[0033] Such as Figure 1 to Figure 3 As shown, the sound generating device provided by the present invention includes a vibrating assembly and a magnetic circuit assembly 3, wherein the vibrating assembly includes a diaphragm 1 and a voice coil 41 combined with the lower side of the diaphragm 1, wherein "up" and "down" are represented by figure 2 The structure shown prevails. The diaphragm 1 includes a middle part 11 at the middle position and a ring part 12 at the edge, wherein the middle part 11 is a hard material, and the strength of the middle part 11 is greater than that of the ring part 12. During the vibration process, the middle The portion 11 is not deformed. The magnetic circuit assembly 3 is located under the diaphragm 1. The magnetic circuit assembly 3 is a dual magnetic circuit structure including a central magnetic circuit at the center and a side magnetic circuit at the edge. A voice coil is formed between the central magnetic circuit and the side magnetic cir...

Embodiment 2

[0057] Such as Figure 4 As shown, there are three main differences between the present embodiment and the implementation of Lee 1. The connection part 7 is a hollow columnar structure, the flexible deformation part 2 is combined with the lower surface of the upper magnetically conductive plate 311, and the flexible deformation part 2 is connected with the upper magnetic plate 311. A support member 5 is provided between the magnetic conductive plates 311 .

[0058] The connection part 7 of this embodiment is a hollow columnar structure, the upper end surface of the connection part 7 is located on the same plane, and the lower end surface of the connection part 7 is located on the same plane. This structure is beneficial to the connection part 7 and the planar middle part 11 and The planar intermediate portion 21 is fixedly joined. Wherein, the upper end surface of the connecting part 7 is fixedly combined with the middle part 11 of the diaphragm 1, and the lower end surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com