Construction method of replacing sealing-tape machine concrete gallery in gravel system with corrugated pipe

A corrugated pipe and concrete technology, which is used in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of long construction time, difficult concrete construction, and narrow construction site, etc., and achieves turnover. The effect of less use of natural materials, short installation period and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

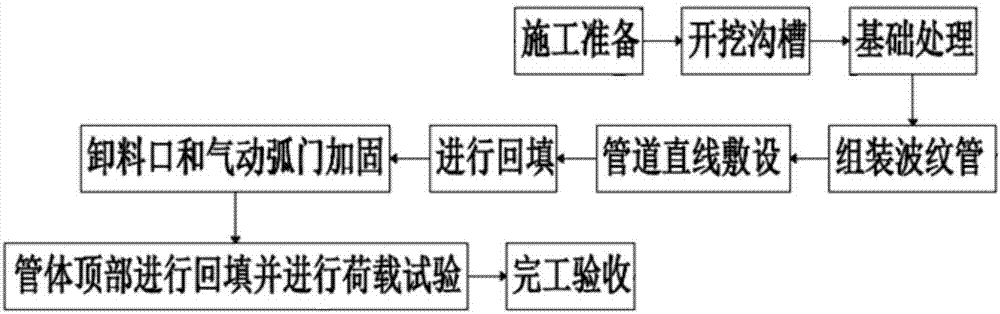

[0043] Such as figure 1 As shown, the construction method of the corrugated pipe replacing the concrete corridor of the belt conveyor in the gravel system includes the following steps:

[0044] ① Bellows selection: Determine the burial depth of the bellows and the material and size of the bellows according to the stacking height of the silo, and determine the size and material of the bellows;

[0045] ②Construction preparation: Prepare auxiliary equipment such as excavators, loaders, cranes, vibrating mills and welding machines, test materials, construction points and equipment and make records; arrange superfine crushing adjustment silos and corrugated pipes for finished silos according to the design drawings location, the silo is divided into an ultrafine crushing adjustment silo and a finished product silo, wherein the ultrafin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com