A kind of graphite/aluminum base self-lubricating sliding bearing containing graphene and preparation method thereof

A sliding bearing and graphene technology, which is applied to shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems of self-lubricating sliding bearings, such as self-heavy weight, poor self-lubricating effect of bearings, and easy environmental pollution, and achieves low processing costs. , the effect of abundant reserves and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

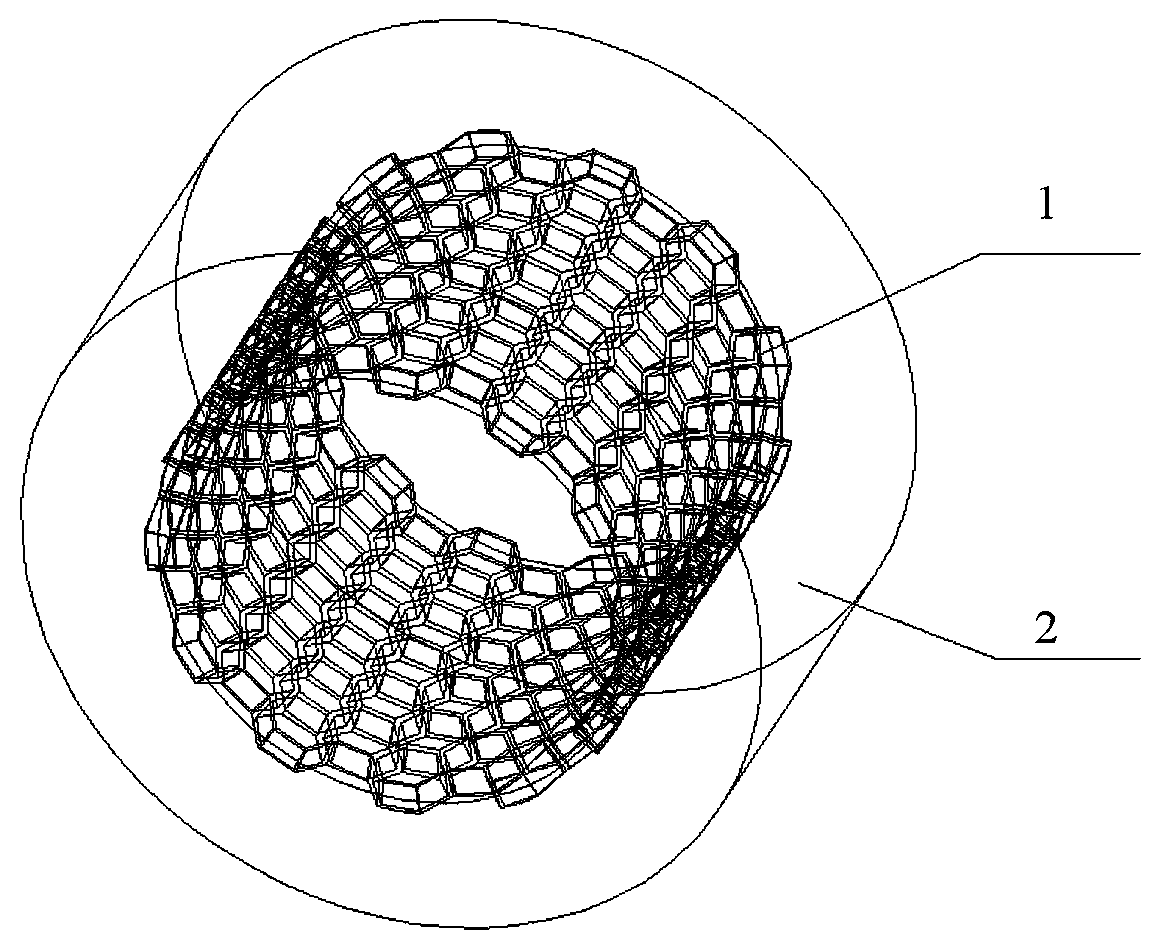

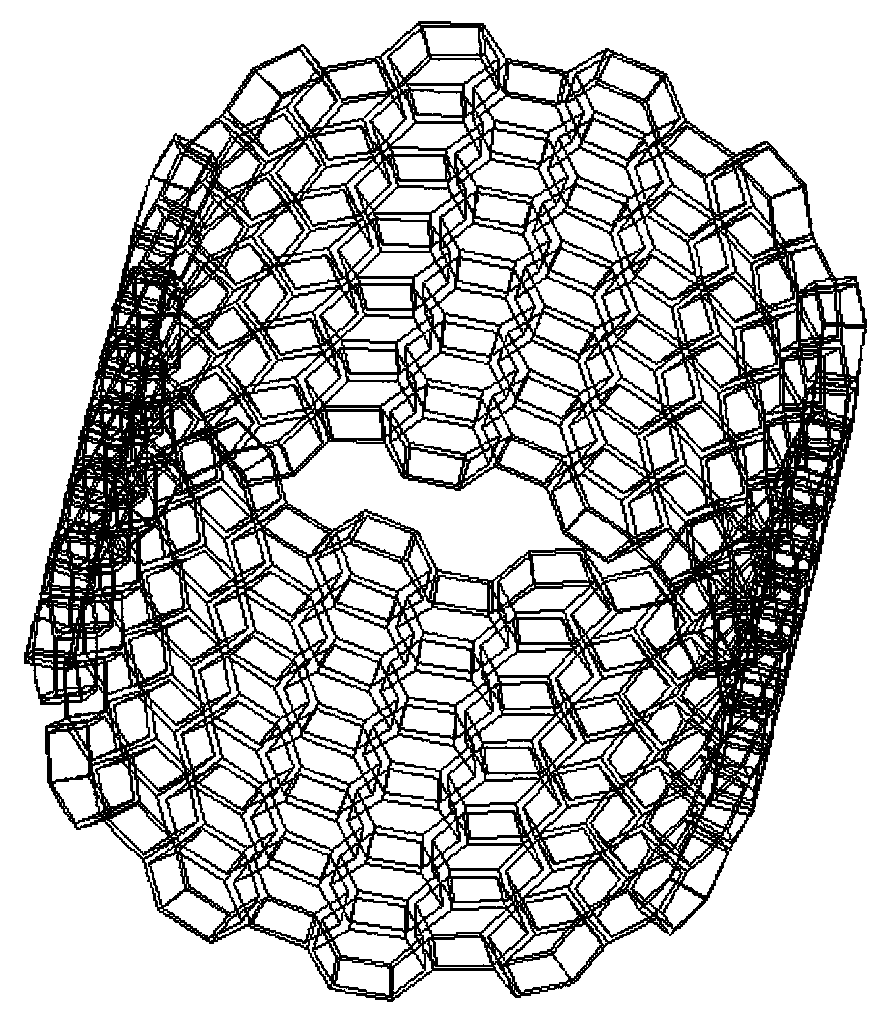

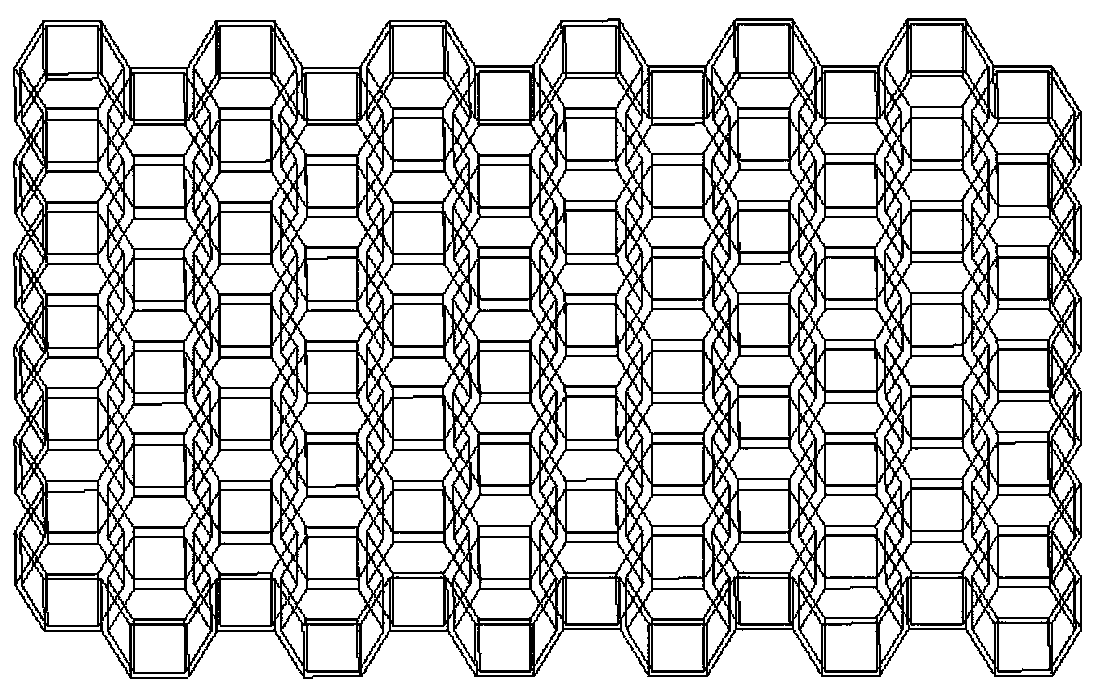

[0032] Such as Figure 8 Shown, a kind of preparation method of graphite / aluminum base self-lubricating sliding bearing containing graphene, it comprises the steps:

[0033] 1) Design a graphite skeleton model with a ring-shaped honeycomb structure through CAD software (such as figure 2 , image 3 , Figure 4 shown), in which the ring-shaped honeycomb structure graphite skeleton, by calculation, its mass fraction is 8% of the inner graphite / aluminum-based self-lubricating composite material layer, the length of a single honeycomb side is 4mm, and the width of a honeycomb side is 0.30mm. The thickness of the graphite skeleton of the annular honeycomb structure is 2 mm.

[0034] 2) Composition of natural flake graphite powder, phenolic resin powder, and graphene in a proportioned mixture, and through selective laser sintering (SLS), according to the skeleton model designed above, a ring-shaped honeycomb structure graphite skeleton green body is prepared . Wherein the pheno...

Embodiment 2

[0043] 1) Design a graphite skeleton model with a ring-shaped honeycomb structure through CAD software (such as figure 2 , image 3 , Figure 4 shown), in which the ring-shaped honeycomb structure graphite skeleton, by calculation, its mass fraction is 10% of the inner graphite / aluminum-based self-lubricating composite material layer, the single honeycomb side length is 4mm, and the honeycomb side width is 0.37mm. The thickness of the graphite skeleton of the annular honeycomb structure is 2 mm.

[0044] 2) Composition of natural flake graphite powder, phenolic resin powder, and graphene in a proportioned mixture, and through selective laser sintering (SLS), according to the skeleton model designed above, a ring-shaped honeycomb structure graphite skeleton green body is prepared . Wherein the phenolic resin is 30% of the mass fraction of the graphite powder, and the content of graphene is 3% of the mass fraction of the overall mixture.

[0045] 3) Bake the graphite skelet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com