Lens assembly system and lens assembly equipment

A technology for assembling devices and lenses, applied in the field of automation, can solve the problems of high cost of manual assembly, easy generation of defective products, etc., and achieve the effect of reducing assembly manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

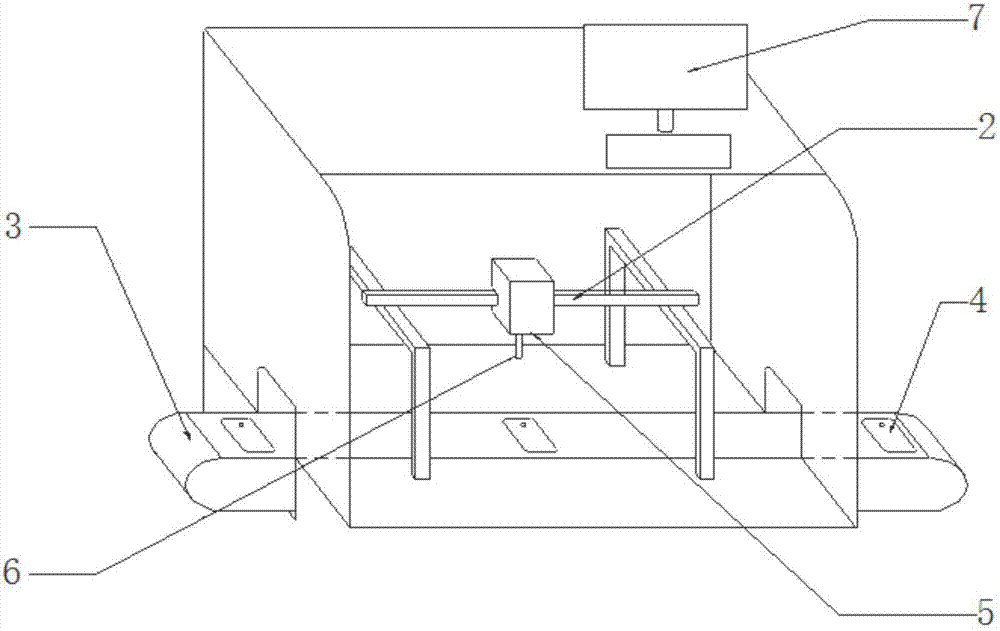

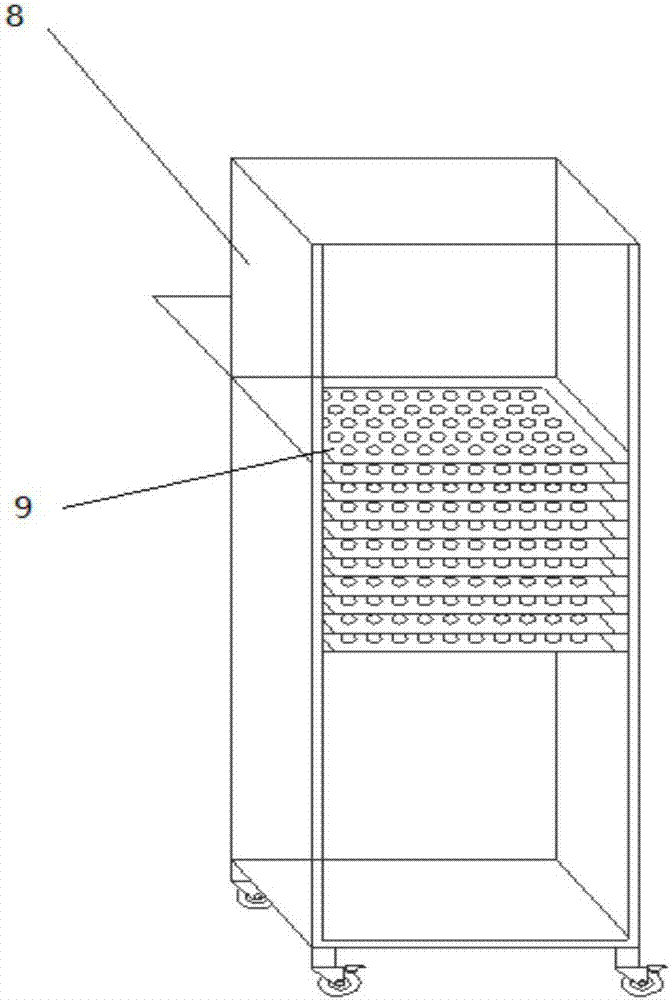

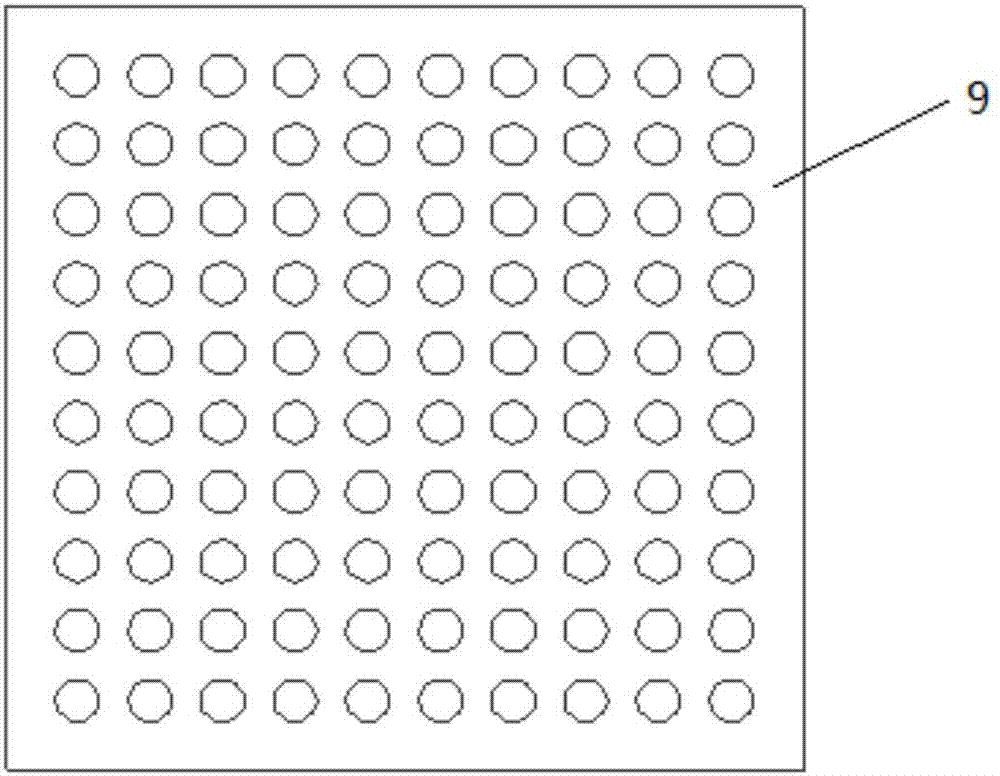

[0042] figure 1 Schematic diagram of the system for assembling lenses provided in Embodiment 1 of the present invention; figure 2 Schematic diagram of the structure of the second feeding device 8 in the system for assembling lenses provided in Embodiment 1 of the present invention; image 3 Schematic diagram of the structure of the tray 9 in the system for assembling lenses provided in Embodiment 1 of the present invention; figure 1 As shown, a system for assembling lenses is provided in this embodiment, and the system for assembling lenses includes: a first feeding device, a visual camera 5 and an assembling device;

[0043] The visual camera 5 is arranged on the assembly device, and the visual camera 5 is used to collect the position information of the lens;

[0044] The first feeding device is used to transfer the imaging equipment body to the assembly position of the lens;

[0045] The assembling device is used for grabbing the lens according to the position informatio...

Embodiment 2

[0070] Figure 4 Schematic diagram of the structure of the equipment for assembling lenses provided by Embodiment 2 of the present invention; Figure 5 The equipment for assembling lenses provided in Embodiment 3 of the present invention plus the schematic structural diagram of the second feeding device 8; as Figure 4 and Figure 5 As shown, the system for assembling lenses provided in this embodiment is a further improvement of the system for assembling lenses provided in Example 1, and the technical solution described in Example 1 also belongs to this embodiment.

[0071] Specifically, as Figure 4 and Figure 5 As shown, a system for assembling lenses is provided in this embodiment, including a frame 1, and the system for assembling lenses;

[0072] The system for assembling lenses is set on the frame 1 .

[0073] The system for assembling lenses includes: a first feeding device, a visual camera 5 and an assembling device;

[0074] The visual camera 5 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com