Limiting and collision preventing structure of cooling refrigerator compressor

A refrigerator compressor, anti-collision technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of compressor influence, compressor stator and rotor gap offset, movement jamming, etc., to avoid metal powder , Guaranteed service life, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

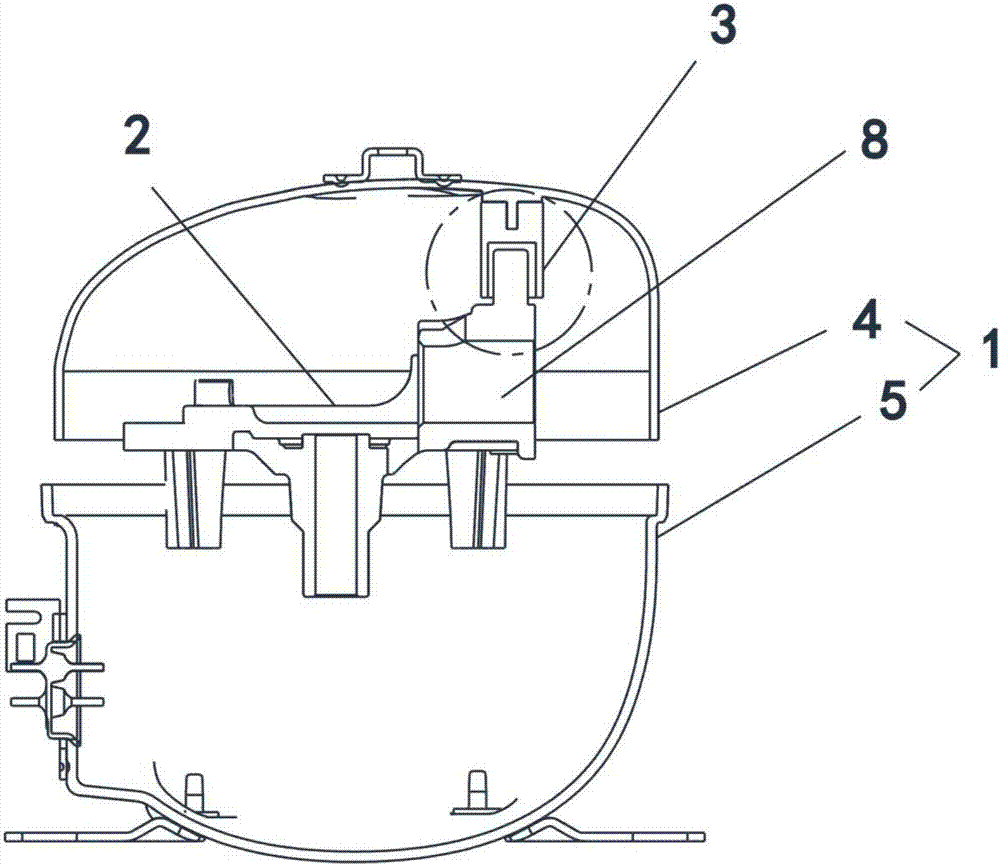

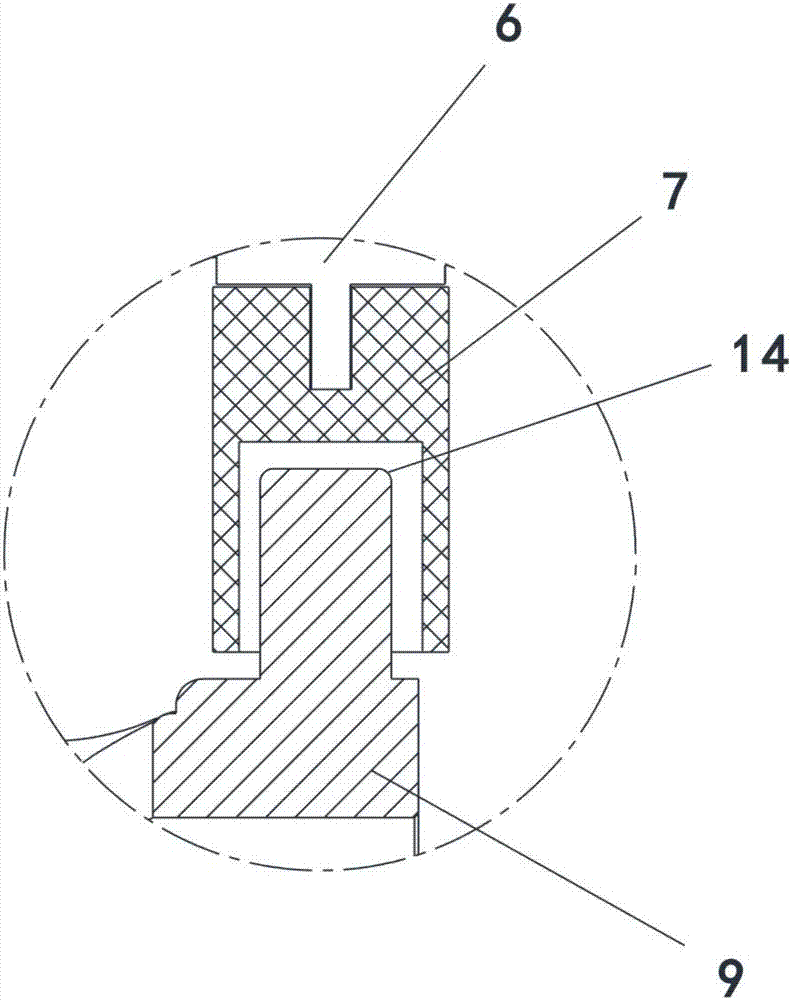

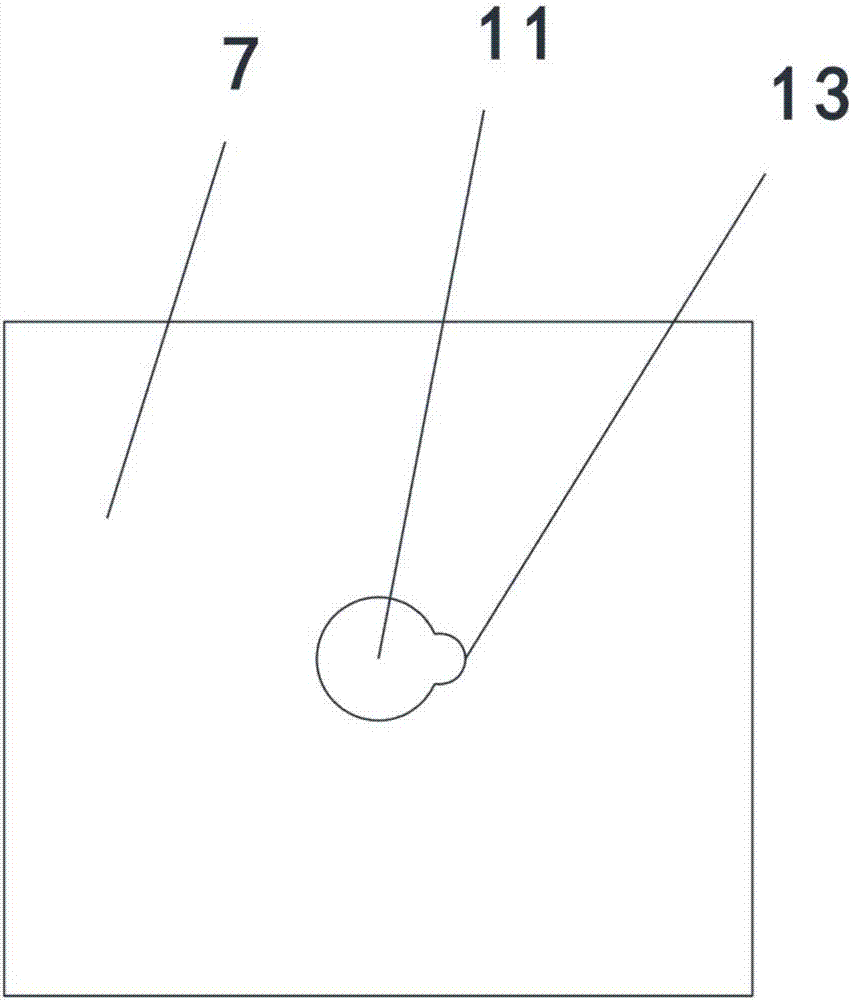

[0029] As an embodiment of the position-limiting and anti-collision structure of the refrigeration refrigerator compressor of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a housing 1, a crankcase 2 and an anti-collision assembly 3, the crankcase 2 and the anti-collision assembly 3 are arranged inside the housing 1, and the anti-collision assembly 3 is arranged on the crankcase 2 Between the housing 1, the housing 1 includes an upper housing 4 and a lower housing 5, the anti-collision assembly 3 includes anti-collision studs 6 and anti-collision bushings 7, the crankcase 2 The upper part is provided with a crankcase cylinder head 8, and the upper part of the crankcase cylinder head 8 is provided with an anti-collision protrusion 9, and the lower surface of the anti-collision bushing 7 is provided with an anti-collision protrusion installation hole 10, and the anti-collision protrusion The anti-collision protr...

Embodiment 2

[0036] As an embodiment of the position-limiting and anti-collision structure of the refrigeration refrigerator compressor of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 6 As shown, it includes a housing 1, a crankcase 2 and an anti-collision assembly 3, the crankcase 2 and the anti-collision assembly 3 are arranged inside the housing 1, and the anti-collision assembly 3 is arranged on the crankcase 2 Between the housing 1, the housing 1 includes an upper housing 4 and a lower housing 5, the anti-collision assembly 3 includes anti-collision studs 6 and anti-collision bushings 7, the crankcase 2 The upper part is provided with a crankcase cylinder head 8, and the upper part of the crankcase cylinder head 8 is provided with an anti-collision protrusion 9, and the lower surface of the anti-collision bushing 7 is provided with an anti-collision protrusion installation hole 10, and the anti-collision protrusion The anti-collision protr...

Embodiment 3

[0040] As an embodiment of the position-limiting and anti-collision structure of the refrigeration refrigerator compressor of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 7 As shown, it includes a housing 1, a crankcase 2 and an anti-collision assembly 3, the crankcase 2 and the anti-collision assembly 3 are arranged inside the housing 1, and the anti-collision assembly 3 is arranged on the crankcase 2 Between the housing 1, the housing 1 includes an upper housing 4 and a lower housing 5, the anti-collision assembly 3 includes anti-collision studs 6 and anti-collision bushings 7, the crankcase 2 The upper part is provided with a crankcase cylinder head 8, and the upper part of the crankcase cylinder head 8 is provided with an anti-collision protrusion 9, and the lower surface of the anti-collision bushing 7 is provided with an anti-collision protrusion installation hole 10, and the anti-collision protrusion The anti-collision protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com