Self-adaptive control system and method for swing speed of cutting arm of cantilever type heading machine

A cantilever-type roadheader and self-adaptive control technology, which is applied to earthwork drilling and cutting machinery, etc., can solve the problems of single criterion, lack of human-computer interaction function, and low cutting efficiency without consideration, so as to reduce work Strength and working pressure, realize automation and intelligence, and ensure the effect of high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

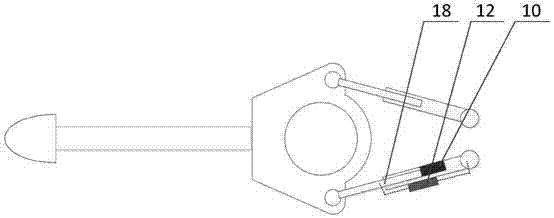

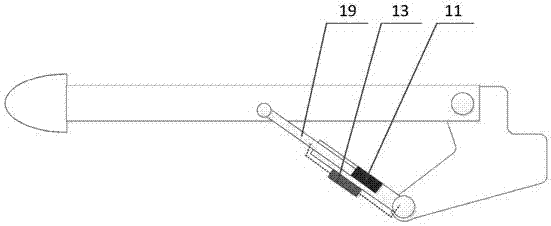

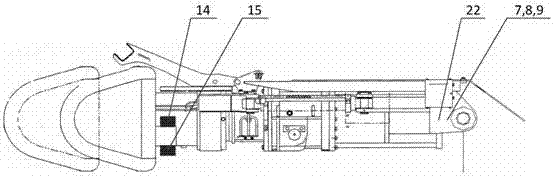

[0048] In order to further illustrate the technical means and effects that the present invention takes to achieve the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the self-adaptive control system for the swing speed of the cutting arm of the cantilever roadheader proposed according to the present invention and its The specific implementation, structure, characteristics and efficacy of the method are described in detail below.

[0049] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the drawings. Through the description of specific implementation methods, the technical means and effects of the present invention to achieve the intended purpose can be understood more deeply and specifically, but the attached drawings are only for reference and description, and are not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com