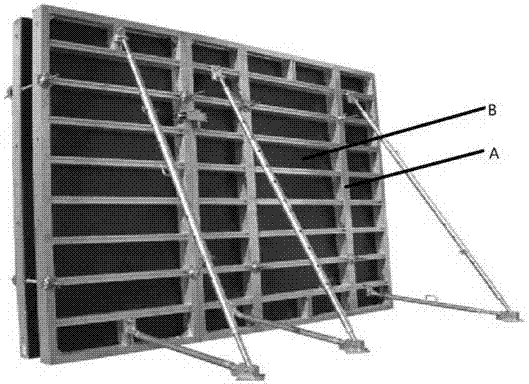

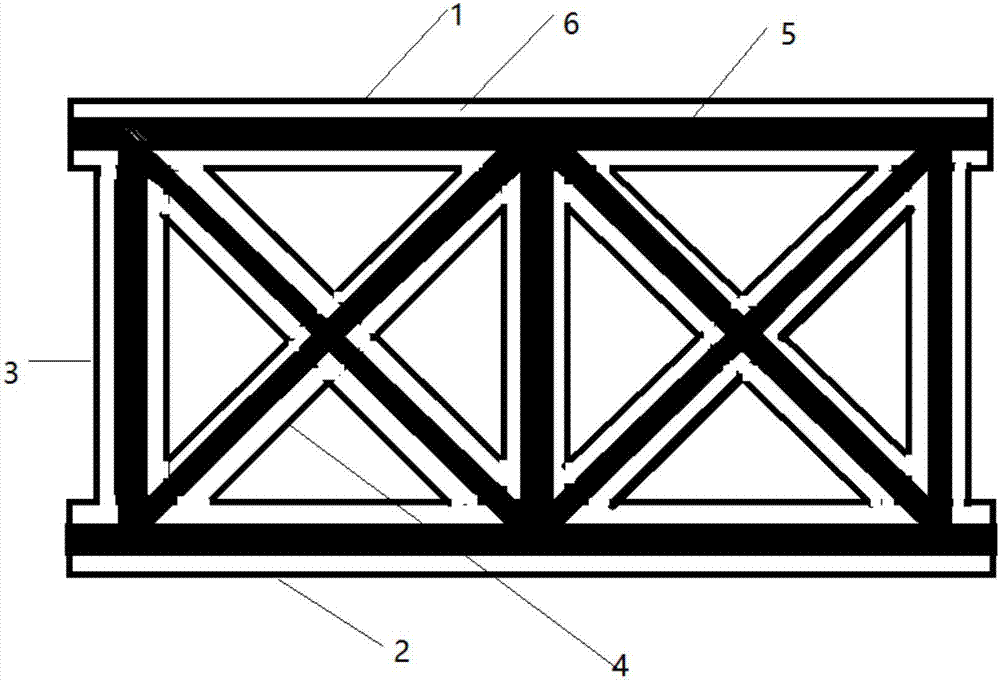

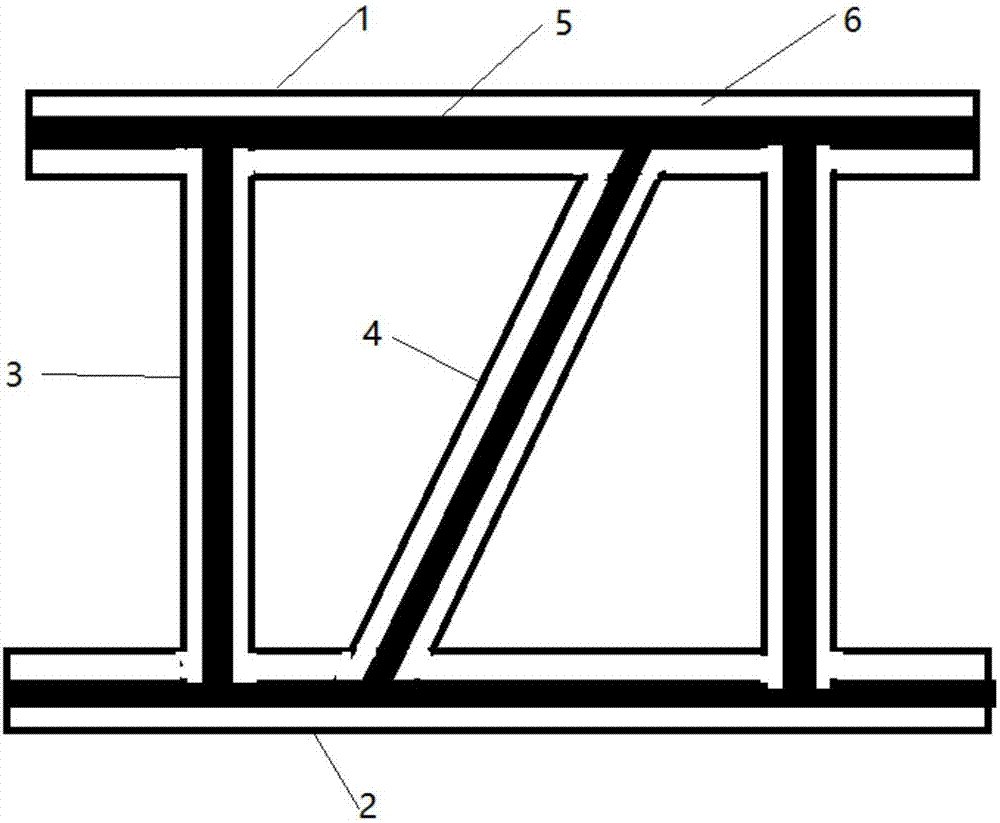

Combined formwork with radio frequency identification electronic chip

A technology of combining templates and electronic chips, which is applied to the preparation of formwork/formwork components and building components on site, construction, etc., to achieve the effects of cost reduction, small heat absorption, and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Proportion according to the following mass percentage, black recycled polypropylene material: colored recycled polypropylene material = 1:1, black recycled polypropylene material: first auxiliary agent: second auxiliary agent = 100:1:10; colored recycled polypropylene material Material: nano aluminum hydroxide: third additive: fourth additive = 100:50:1:10, wherein the mass composition of the first additive is 4,4'-bismaleimide diphenylmethane : EPDM rubber-maleic anhydride graft: polypropylene-maleic anhydride graft: calcium stearate: silane coupling agent = 2:3:3:15:20; the quality of the second additive The composition is, 2,4-cresyl diisocyanate: graphite long fibers with a length of 200 microns = 1:10; the mass composition of the third additive is, 4,4'-bismaleimide diphenylmethane : calcium stearate: silane coupling agent=2:15:20; the mass composition of the fourth auxiliary agent is, 2,4-cresyl diisocyanate: graphite short fiber with a length of 10 microns=1:16. ...

Embodiment 2

[0052] Proportion according to the following mass percentages, black recycled polypropylene material: colored recycled polypropylene material = 1:1, black recycled polypropylene material: first auxiliary agent: second auxiliary agent = 100:5:30; colored recycled polypropylene Material: nano-magnesium hydroxide: third additive: fourth additive = 100:50:5:30, wherein the mass composition of the first additive is 4,4'-bismaleimide diphenylmethane : EPDM rubber-maleic anhydride graft: polypropylene-maleic anhydride graft: calcium stearate: silane coupling agent = 1:2:2:4:6; the quality of the second additive The composition is, 2,4-cresyl diisocyanate: graphite long fibers with a length of 300 microns = 1:10; the mass composition of the third additive is, 4,4'-bismaleimide diphenylmethane : calcium stearate: silane coupling agent=5:20:30; the mass composition of the 4th auxiliary agent is, 2,4-cresyl diisocyanate: length is the short graphite fiber=1:10 of 50 microns, Other proce...

Embodiment 3

[0054] Proportion according to the following mass percentages, black recycled polypropylene material: colored recycled polypropylene material = 1:1, black recycled polypropylene material: first additive: second additive = 100:3:20; colored recycled polypropylene Material: Phosphate: Third additive: Fourth additive = 100:30:3:20, wherein the mass composition in the first additive is, 4,4'-bismaleimide diphenylmethane: three Yuan ethylene propylene rubber-maleic anhydride graft: polypropylene-maleic anhydride graft: calcium stearate: silane coupling agent=1:2:2:5:10; the mass composition of the second auxiliary agent is , 2,4-cresyl diisocyanate: graphite long fibers with a length of 200 microns = 1:8; the mass composition of the third additive is, 4,4'-bismaleimide diphenylmethane: hard Calcium fatty acid: silane coupling agent = 1:5:10; the mass composition of the fourth auxiliary agent is, 2,4-diisocyanate toluene: graphite short fiber with a length of 30 microns = 1:8, other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com