High-efficiency energy-saving full-automatic back-flush non-negative-pressure water supply device

A high-efficiency energy-saving technology for water supply equipment, applied in water supply devices, water supply main pipelines, water supply pipeline systems, etc., can solve the problems of water pumps that cannot be stopped, tap water pollution, and affecting the health of residents, and achieve the effect of saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

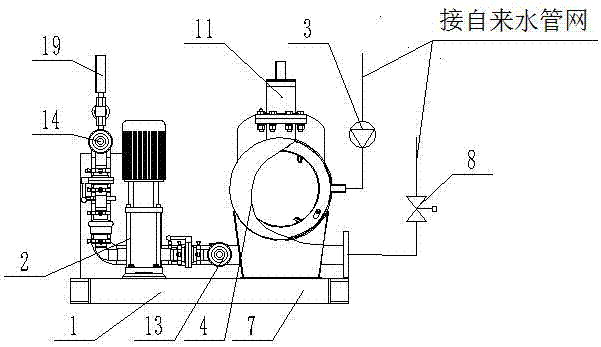

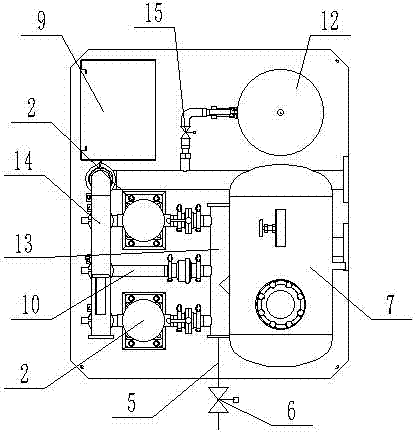

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

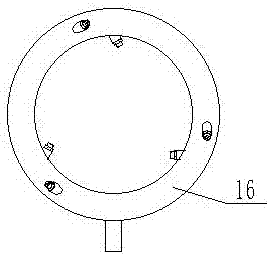

[0030] A high-efficiency and energy-saving fully automatic backwashing non-negative pressure water supply equipment, comprising a support 1, a flow stabilization tank 7, a booster water pump 2, an accumulator 12, and a control cabinet 9 are arranged above the support 1. The top of the tank 7 is provided with a negative pressure eliminator 11 and a pressure gauge 19, the inlet end is connected to the tap water pipe network controlled by the water inlet electric control valve 8, and the outlet end is connected to the water inlet main pipe 13; one end of the water inlet main pipe 13 is connected through The drain pipe 5 controlled by the drain electric control valve 6; the inlet end of the booster water pump 2 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com