Continuous rotation electrolysis method and device for lead solution

A lead solution and solution technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of long process route and high processing cost, and achieve the effects of high operating efficiency, stable processing capacity, and economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

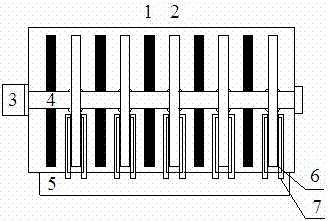

Image

Examples

Embodiment 1

[0026] Adopt device and method of the present invention to electrolyze lead acetate solution, lead ion concentration 1mol / L, solution feeding speed 0.2L / min, current density 180A / m 2 , electrolyzed for 60 minutes to obtain 2.36kg of lead.

Embodiment 2

[0028] Adopt device and method of the present invention to electrolyze lead chloride solution, lead ion concentration 1.2 mol / L, solution feeding speed 0.1L / min, current density 160A / m 2 , electrolyzed for 60 minutes to obtain 1.45kg of lead.

Embodiment 3

[0030] Using the device and method of the present invention to electrolyze the lead fluorosilicate solution, the lead ion concentration is 2.0 mol / L, the solution feed rate is 0.1L / min, and the current density is 200A / m 2 , electrolyzed for 60 minutes to obtain 2.41kg of lead.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com