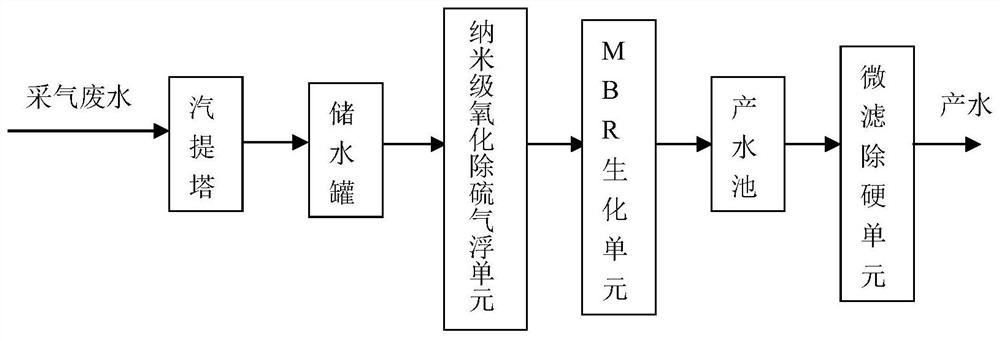

A pretreatment process for desulfurization and purification of gas extraction wastewater

A gas extraction wastewater and pretreatment technology, applied in multi-stage water treatment, water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of inability to achieve resource reuse, heavy workload, high cost, etc., and achieve water discharge The effect of good water quality, reduced dosage and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Gas production wastewater from a gas field, the water quality is: pH 7.2, H 2 S is 5000mg / L, COD is 1530mg / L, total nitrogen is 80mg / L, and total hardness is 2560mg / L.

[0046] The waste water from gas extraction enters the stripping tower, the temperature of the bottom of the stripping tower is 160°C, the temperature of the top of the stripping tower is 105°C, and the pressure of the stripping tower is 0.6MPa. After desulfurization by the stripper, the H in the wastewater 2 The S content was reduced from 5000mg / L to 105mg / L. The steamed water enters the water storage tank, and is pumped into the nano-scale oxidation desulfurization air flotation unit through the pipeline. 27% hydrogen peroxide 590 mg / L is added to the pipeline, and hydrochloric acid is added to adjust the pH value to 5. The reaction time is about 5 minutes. H in water 2 The S content dropped to 25mg / L. Dosing NaHCO before the oxidized effluent enters the anoxic biochemical pool 3 Adjust the pH of ...

Embodiment 2

[0050] Gas production wastewater from a gas field, the water quality is: pH 8.3, H 2 S is 3370mg / L, COD is 2235mg / L, total nitrogen is 150mg / L, and total hardness is 3580mg / L.

[0051] The waste water from gas extraction enters the stripping tower, the temperature of the bottom of the stripping tower is 140°C, the temperature of the top of the stripping tower is 95°C, and the pressure of the stripping tower is 0.4MPa. After desulfurization by the stripper, the H in the wastewater 2 The S content dropped from 3370mg / L to 95mg / L. The steamed water enters the water storage tank, and is pumped into the nano-scale oxidation desulfurization air flotation unit through the pipeline. 27% hydrogen peroxide 388mg / L is added to the pipeline, and hydrochloric acid is added to adjust the pH value to 6. The reaction time is about 20min. H in water 2 The S content dropped to 25mg / L. Dosing NaHCO before the oxidized effluent enters the anoxic biochemical pool 3 Adjust the pH of the oxidiz...

Embodiment 3

[0055] Gas production wastewater from a gas field, the water quality is: pH 8.0, H 2 S is 3520mg / L, COD is 1920mg / L, total nitrogen is 106mg / L, and total hardness is 1780mg / L.

[0056] The waste water from gas extraction enters the stripping tower, the temperature of the bottom of the stripping tower is 110°C, the temperature of the top of the stripping tower is 85°C, and the pressure of the stripping tower is 0.15MPa. After desulfurization by the stripper, the H in the wastewater 2 The S content dropped from 3520mg / L to 82mg / L. The steamed water enters the water storage tank, and is pumped into the nano-scale oxidation desulfurization air flotation unit through the pipeline. 30% sodium hypochlorite 237mg / L is added to the pipeline, and sulfuric acid is added to adjust the pH value to 4.5. The reaction time is about 15min. H in water 2 The S content dropped to 20mg / L. Before the oxidized effluent enters the anoxic biochemical pool, add NaOH to adjust the pH of the oxidized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com