Lifting machine

A lift and lift component technology, applied in the field of lifts, can solve the problems that lifts cannot be moved at will, increase maintenance costs, increase costs, etc., and achieve the effects of facilitating installation, ensuring battery life, and improving support effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

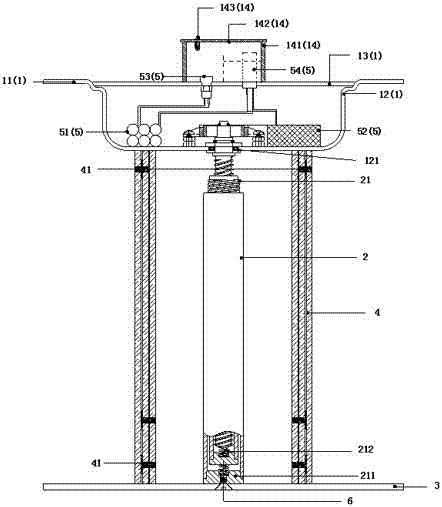

[0027] a lift such as figure 1 As shown, the bearing platform 1 is a sinking structure, with a recessed hidden section 12 in the middle, and a suspended support section 11 around it. A cover 13 is provided above the hidden section 12, and the upper middle part of the cover 13 is There is a control area 14, the middle position of the hidden section 12 is connected to the lifting assembly 2 downwards, and the aluminum alloy column 4 including the lifting assembly 2 is connected downwards around it, and the lifting assembly 2 and the aluminum alloy column 4 are fixed on the base on the seat plate 3.

[0028] The elevator also includes a control assembly 5. Specifically, the control assembly 5 includes a power storage device 51, a motor 52, a charging port 53 and a lifting switch 54, wherein the power storage device 51 and the motor 52 are arranged in the hidden section 12, and the charging port 53 The lift switch 54 is arranged in the control area 14 , the charging port 53 is el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com