All-metal hollow dot matrix-honeycomb mixed sandwich structure and interlocking preparation method thereof

A sandwich structure, all-metal technology, applied in underwater anti-explosion, aerospace, marine, transportation and construction fields, can solve the problem of poor energy absorption effect, achieve improved surface-core connection strength, excellent energy absorption characteristics, The effect of increasing the shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

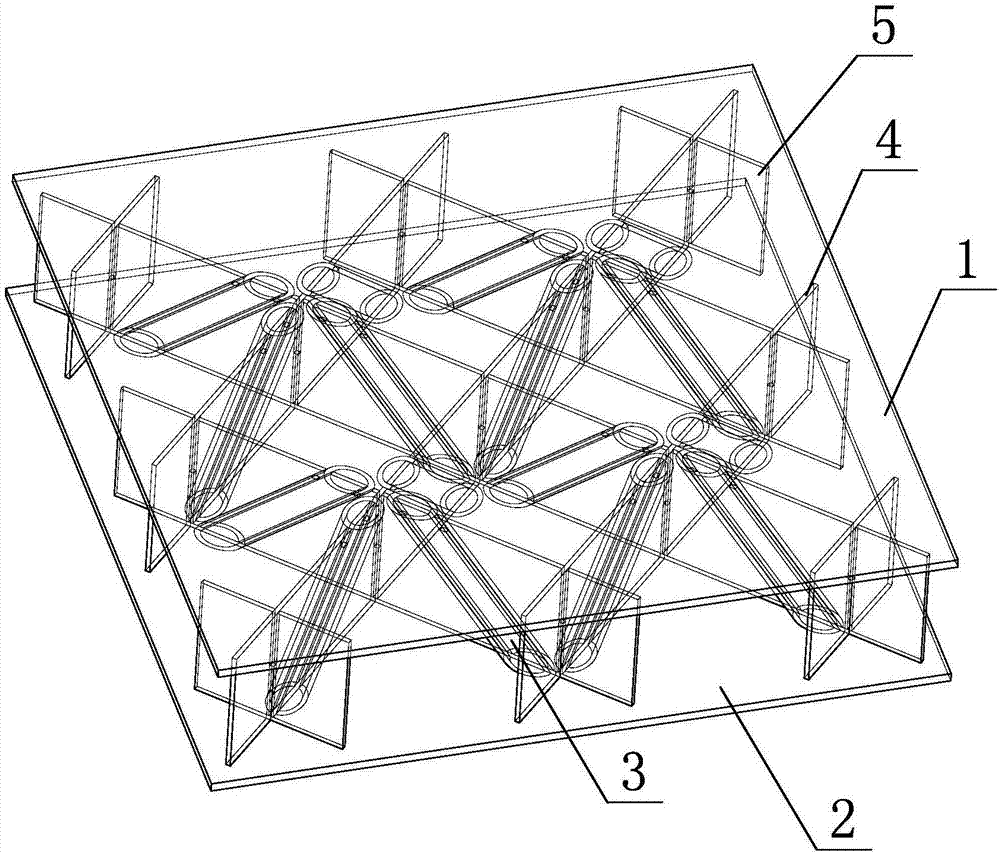

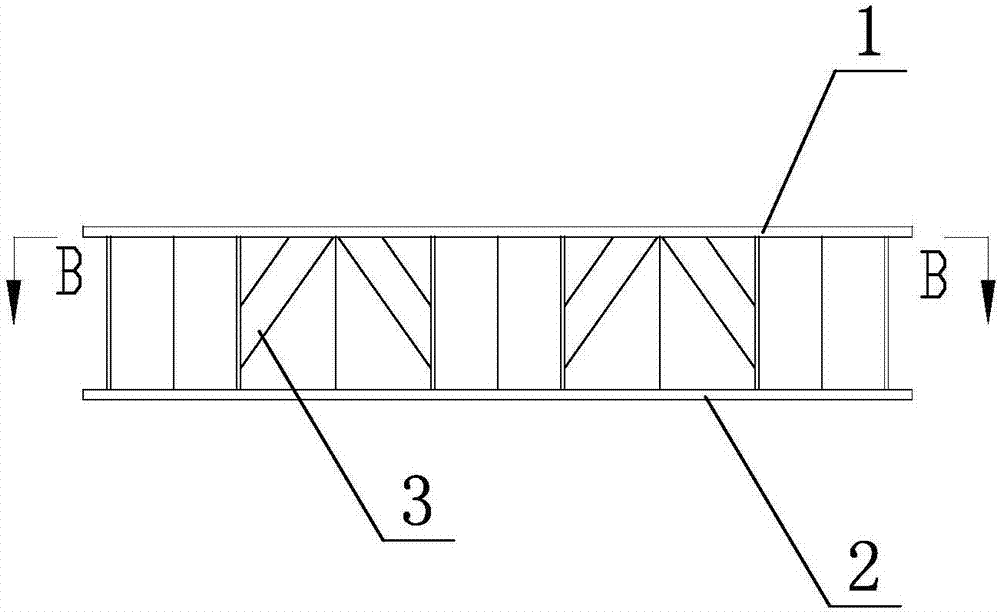

[0037] Specific implementation mode one: combine Figure 1 to Figure 15 Describe this embodiment, an all-metal hollow pyramid lattice-square honeycomb hybrid sandwich panel device in this embodiment includes an upper panel 1 and a lower panel 2, the upper panel 1 and the lower panel 2 are arranged in parallel up and down, and it also includes a square The honeycomb interlocking assembly and a plurality of inclined circular tubes 3 with long and narrow slots, the square honeycomb interlocking assembly is installed between the upper panel 1 and the lower panel 2, and multiple inclined round tubes 3 with narrow and long slots are obliquely inserted and locked in The oblique circular tube of the square honeycomb interlocking component is embedded in the interlocking groove.

[0038] On the basis of retaining the complete square honeycomb structure, the cutting-interlocking preparation process of the present invention skillfully kneads the hollow pyramid lattice structure and the s...

specific Embodiment approach 2

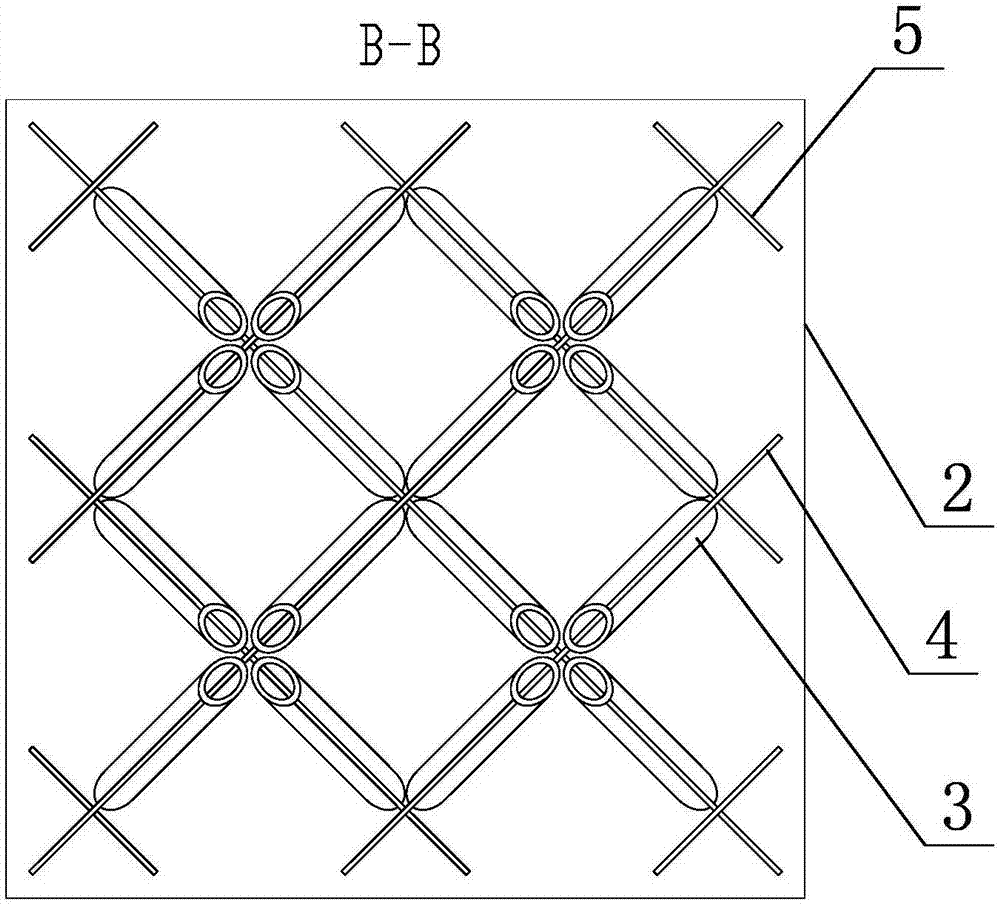

[0039] Specific implementation mode two: combination Figure 1 to Figure 11 Describe this embodiment, the square honeycomb interlocking assembly of this embodiment includes a plurality of first locking pieces 4 and a plurality of second locking pieces 5, a plurality of first locking pieces 4 are arranged in parallel at equal intervals, and a plurality of second locking pieces 5 Equidistantly arranged in parallel and interlocked one by one on multiple first locking pieces 4 . With such arrangement, it is convenient to form a square honeycomb interlocking component, and the assembly process is simple. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Specific implementation mode three: combination Figure 1 to Figure 11 To describe this embodiment, the upper parts of the plurality of first locking pieces 4 and the lower parts of the plurality of second locking pieces 5 of this embodiment are provided with inserting and interlocking grooves 6 at equal intervals. Such an arrangement facilitates interlocking and plugging of multiple first locking pieces 4 and multiple second locking pieces 5 , and accurate installation and positioning. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com