Efficient modular saturated steam washing equipment

A cleaning equipment and a modular technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of insufficient electric heating power, increased energy consumption, low electric heating efficiency, etc., and achieve improved Improve equipment space utilization, improve installation and maintainability, and improve the effect of electric heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

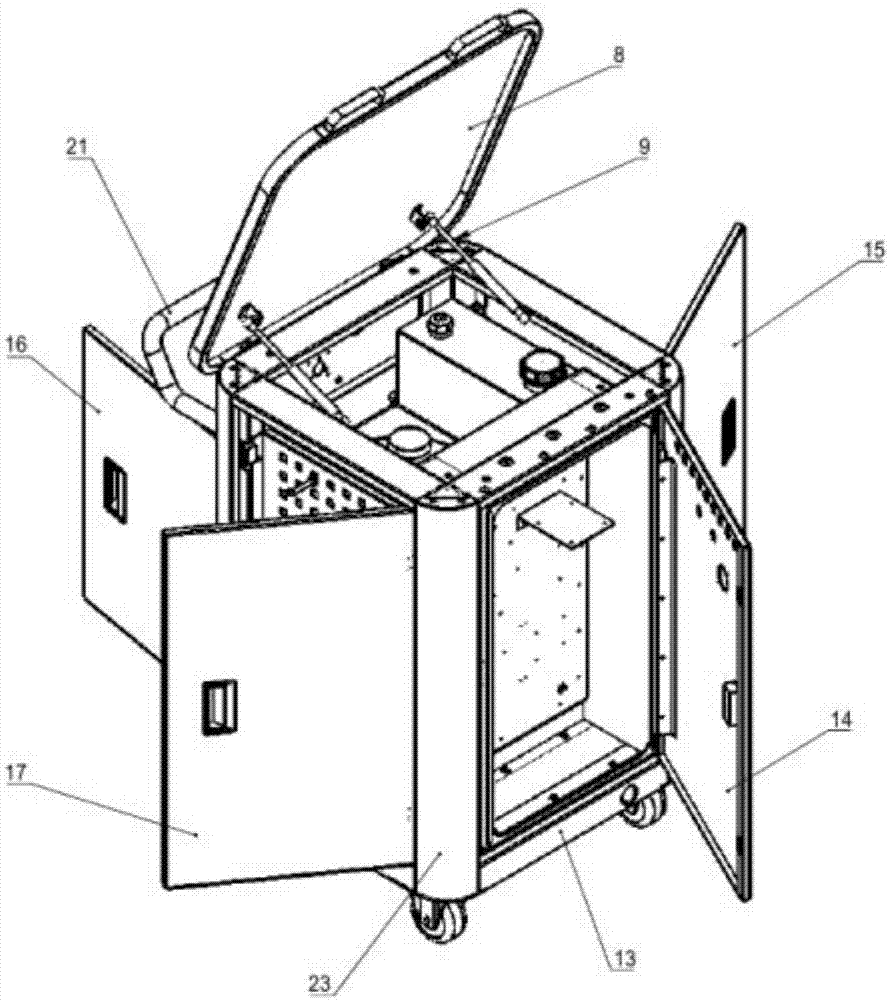

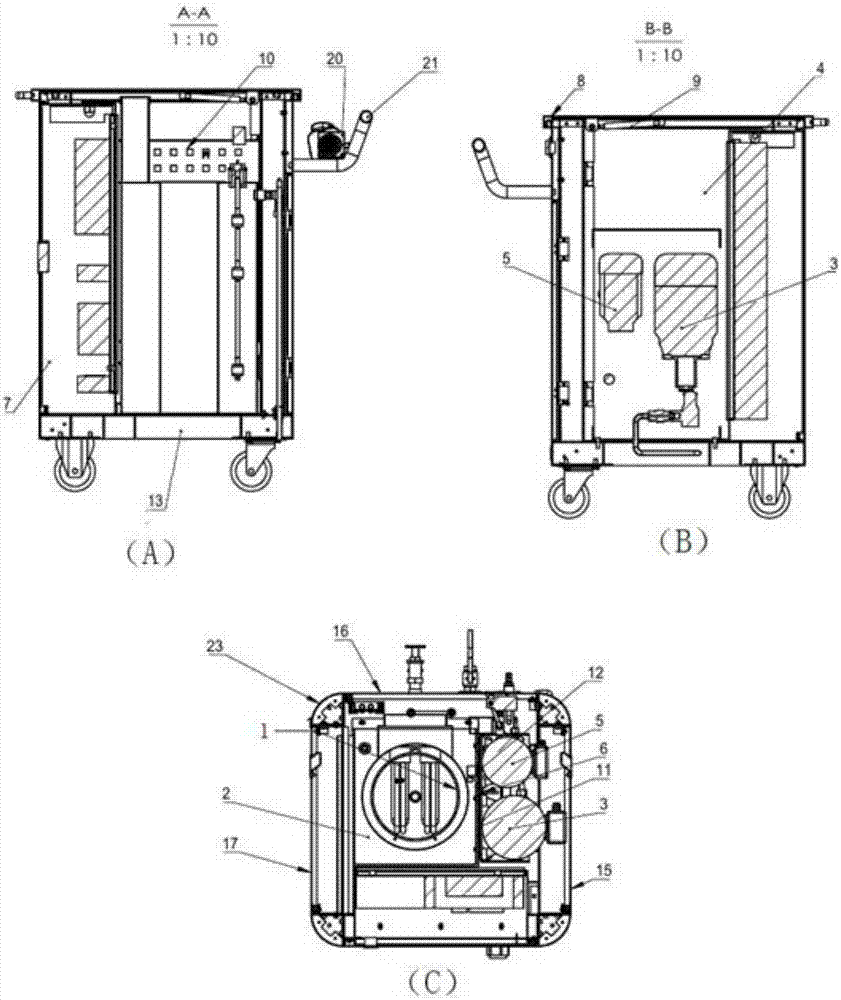

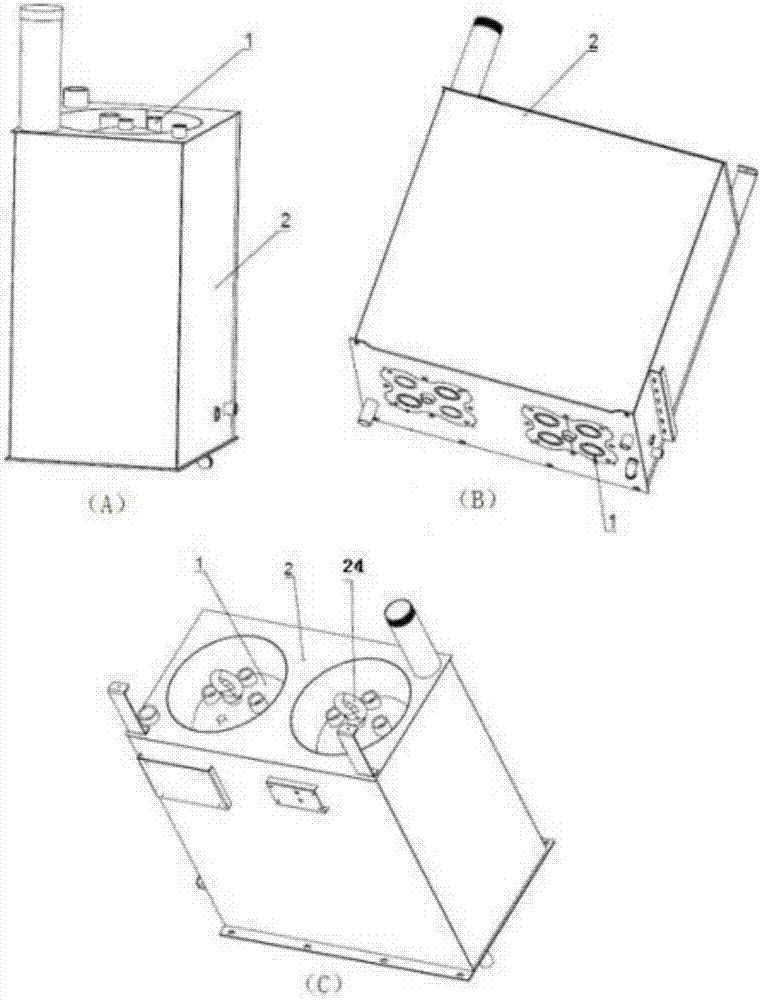

[0039] Such as Figure 1 to Figure 8 As shown, a novel high-efficiency saturated steam cleaning equipment includes an equipment chassis 13, a steam generator 1, a water tank 2, a water pump 3, a liquid medicine tank 4, a liquid medicine pump 5 and a cleaning gun head 18, and the water pump 3 is connected with the cleaning gun head 18 respectively. The steam generator 1 is connected to the water tank 2, the water pump 3 transports the water in the water tank 2 to the steam generator 1, the liquid medicine pump 5 is connected to the liquid medicine tank 4, and the cleaning gun head 18 is connected to the steam through a towing line 19. The outlet of device 1 is communicated with the outlet of liquid medicine pump 5.

[0040] Such as figure 1 and figure 2 As shown, the equipment chassis 13 is a three-dimensional internal hollow structure and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com