Rotary type double-acting mixer

A mixer and rotary type technology, applied in mixers, mixers with rotating containers, mixing methods, etc., can solve the problems of low efficiency and insufficient dispersion of materials, and achieve product quality assurance and good mixing and dispersing effect. , to prevent the effect of unmixed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

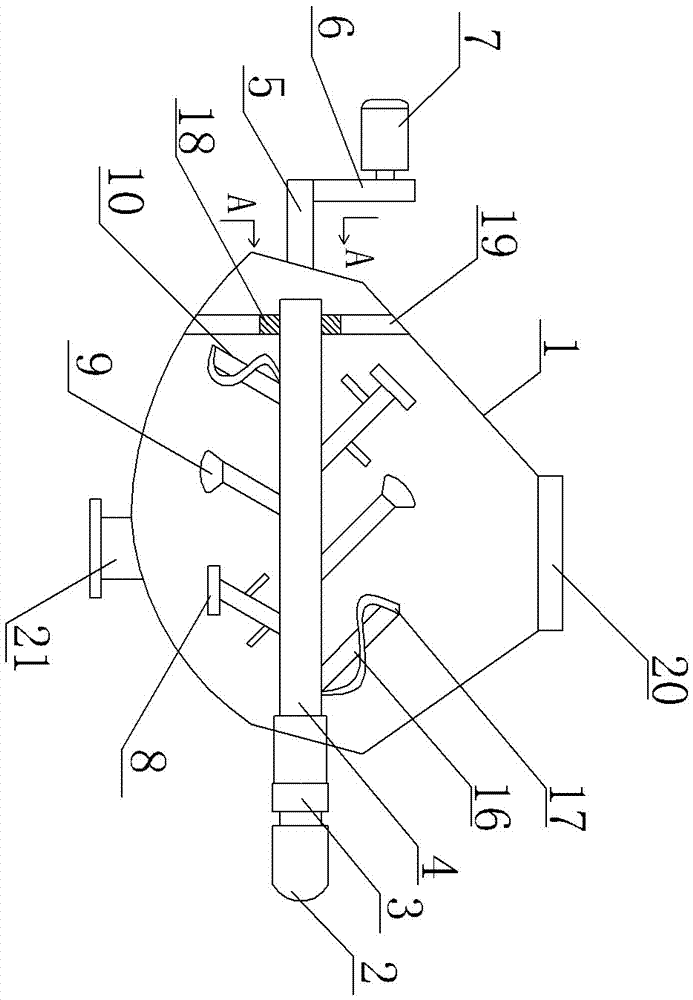

[0016] Such as Figure 1~Figure 4 As shown, a rotary mixer includes a cylinder body 1 and a main shaft motor 2 arranged on one side of the cylinder body 1, and the main shaft motor 2 is connected to one end of the main shaft 4 extending into the cylinder body 1 in the horizontal direction through a coupling 3 , a stirring device is installed on the main shaft 4, and a pulley shaft 5 is installed on the other side of the cylinder body 1. The pulley shaft 5 is connected to the cylinder motor 7 through a belt transmission device 6. The upper part of the cylinder body 1 has a left-right asymmetrical double-cone structure, and the lower Spherical shape.

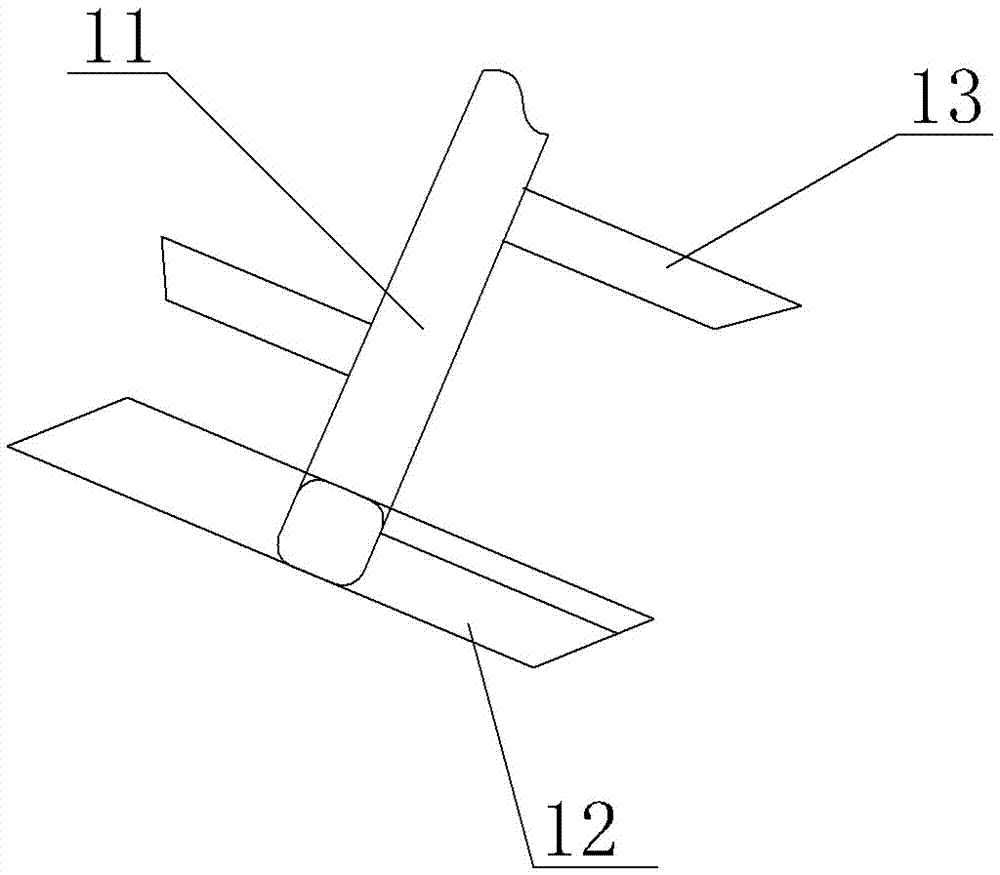

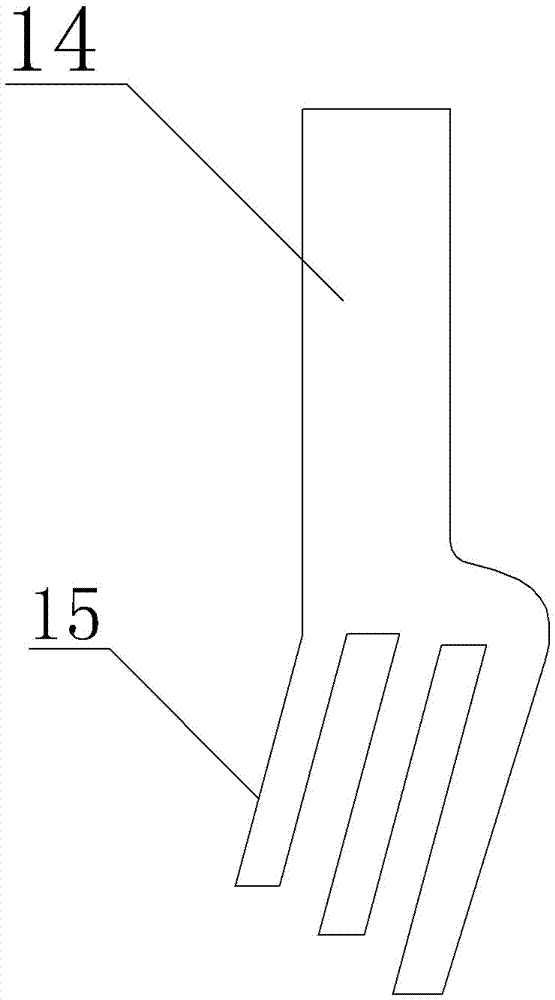

[0017] The stirring device comprises a first stirring paddle 8, a second stirring paddle 9, and a third stirring paddle 10 arranged obliquely, and the inclination angles of the first stirring paddle 8, the second stirring paddle 9, and the third stirring paddle 10 are all less than 90°, Can increase the mixing effect, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com