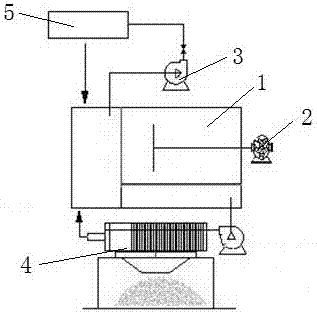

Baffling desulfurizing liquid circulating device in flue gas desulfurization system and application method

A desulfurization system and circulation device technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of large floor space and high investment costs, prevent secondary pollution, solve high investment costs, and reduce retention the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

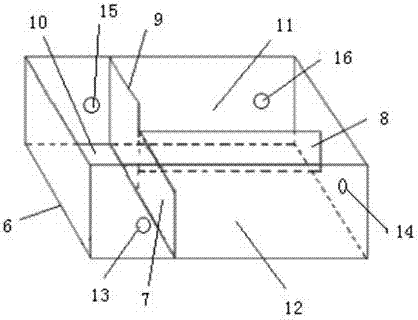

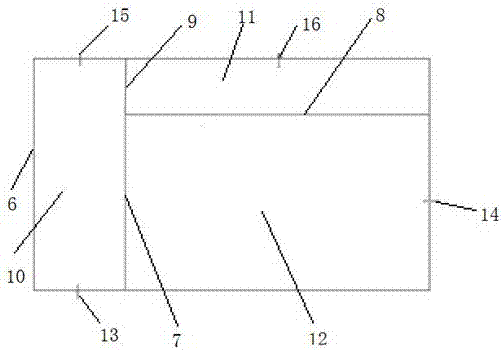

[0034] Using lime water as SO 2 The desulfurizing agent is the alkaline desulfurization mother liquor, the initial pH value of the alkaline desulfurization mother liquor is adjusted to 9.8, and the desulfurization process controls the internal temperature of the desulfurization device 5 to be 25°C, containing SO 2 The flue gas is sent into the desulfurization device 5 from the lower part of the desulfurization device 5 through the intake pump, the intake flow rate is 5L / min, and the SO in the flue gas 2 The concentration is 1200mg / m 3 , O 2 The content is 6%. The alkaline desulfurization mother liquor is prepared by the pulping tank, and then pumped into the baffle circulation pool 1 through the booster pump, and sent to the top of the desulfurization device 5 by the circulation pump 5 for spraying, and the SO in the flue gas 2 After the countercurrent contact reaction in the desulfurization device 5, it returns to the circulation tank 10, where it is mixed with the origina...

Embodiment 2

[0036] Using lime water as SO 2 The desulfurizer is the alkaline desulfurization mother liquor, the initial pH value of the alkaline desulfurization mother liquor is adjusted to 8.8, the desulfurization process controls the internal temperature of the desulfurization device 5 to be 25 ° C, and the SO 2 The flue gas is sent into the desulfurization device 5 from the lower part of the desulfurization device 5 through the intake pump, the intake flow rate is 5L / min, and the SO in the flue gas 2 The concentration is 1200mg / m 3 , O 2 The content is 6%. The alkaline desulfurization mother liquid enters the circulation tank 10 from the alkaline desulfurization liquid inlet 13, and is sent to the top of the desulfurization device 2 by the circulation pump 3 for spraying, and the SO in the flue gas 2 After the countercurrent contact reaction in the desulfurization device 2, it returns to the circulation tank 10, and is mixed with the original desulfurization liquid to form a desulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com