Silicon carbide TrenchMOS device and manufacturing method thereof

A technology of silicon carbide and devices, which is applied in the field of silicon carbide TrenchMOS devices and its production, can solve the problems of high power loss, low work efficiency, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

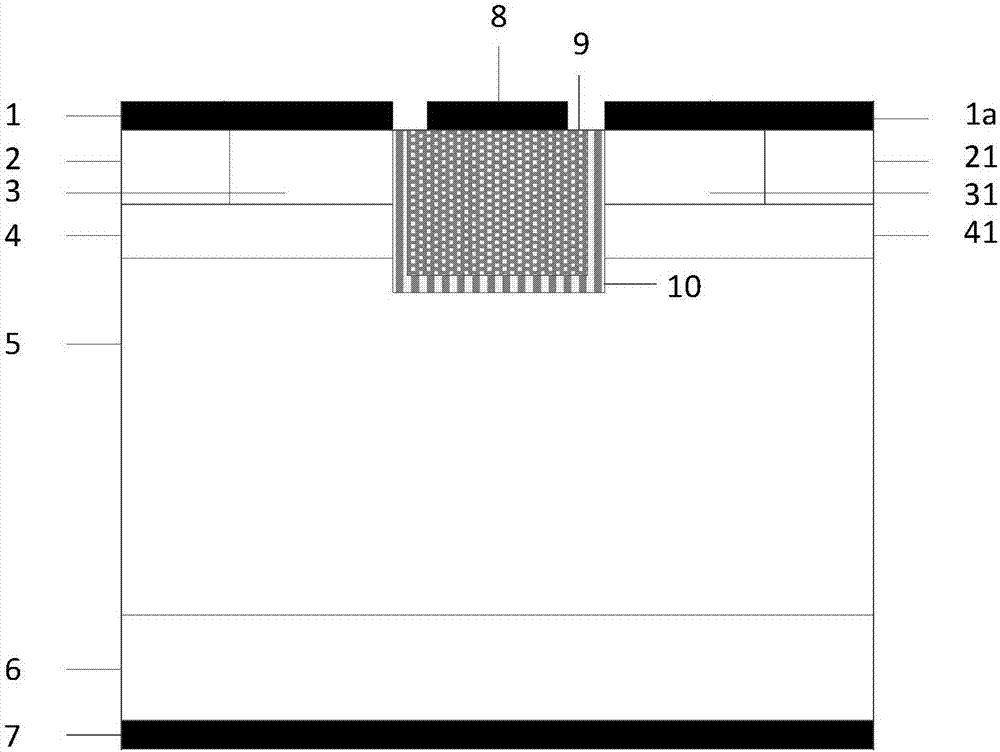

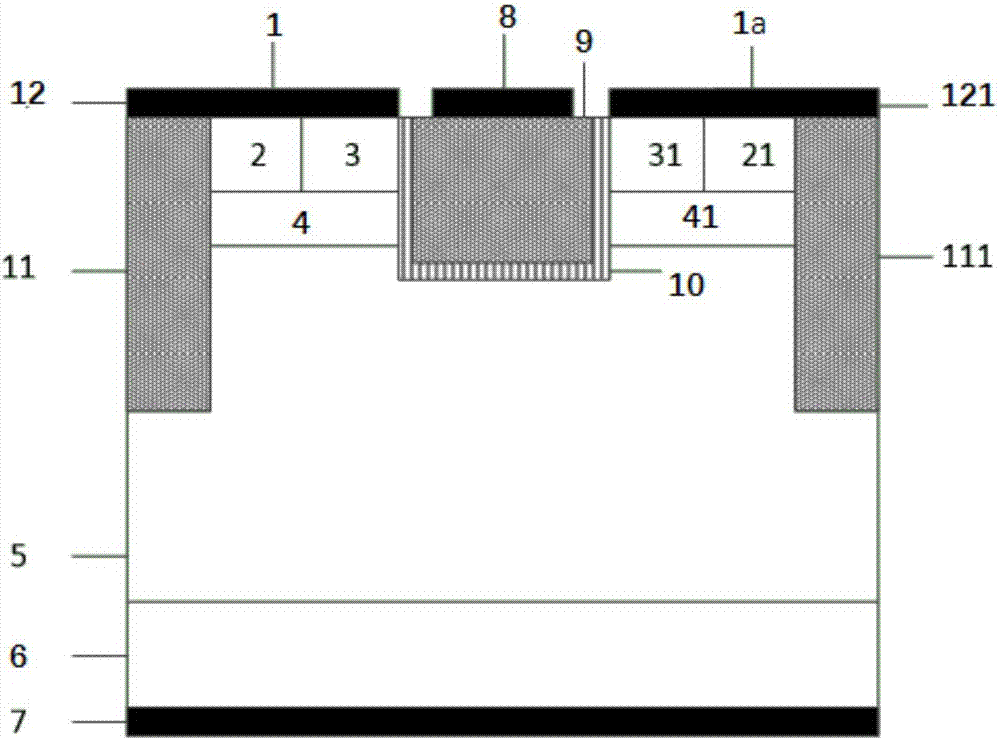

[0099] A silicon carbide Trench MOS device, its cell structure is as follows figure 2 Shown includes: metal drain electrodes 7, N + Substrate 6 and N - Epitaxial layer 5; characterized in that: the N - The two ends of the upper layer of the epitaxial layer 5 respectively have first P + polysilicon region 11 and the second P + polysilicon region 111, the first P + polysilicon region 11 and the second P + The upper surface of the polysilicon region 111 is respectively provided with a first metal electrode 12 and a second metal electrode 121; + N between the polysilicon regions 11, 111 - The epitaxial layer 5 has a Trench gate structure, and the Trench gate structure includes a polysilicon gate 9, a gate oxide layer 10 disposed on the bottom surface and sidewalls of the polysilicon gate 9, and a metal gate 8 disposed on the upper surface of the polysilicon gate 9; + N between the polysilicon region 11 and the Trench gate structure - The upper layer of the epitaxial layer ...

Embodiment 2

[0102] This implementation except in the first P + polysilicon region 11 and the second P + There is a first P in contact with the polysilicon region 111 below + SiC region 14 and the second P + SiC region 141; the P +The width of the silicon carbide region 14, 141 and P + The polysilicon region 11 has the same width, as image 3 shown.

[0103] The P added in this embodiment + The SiC region 14, 141 is able to P + The polysilicon regions 11, 111 and the trench gate play the role of electric field shielding, thereby improving the withstand voltage of the device, and have a certain effect on suppressing the reverse leakage current.

Embodiment 3

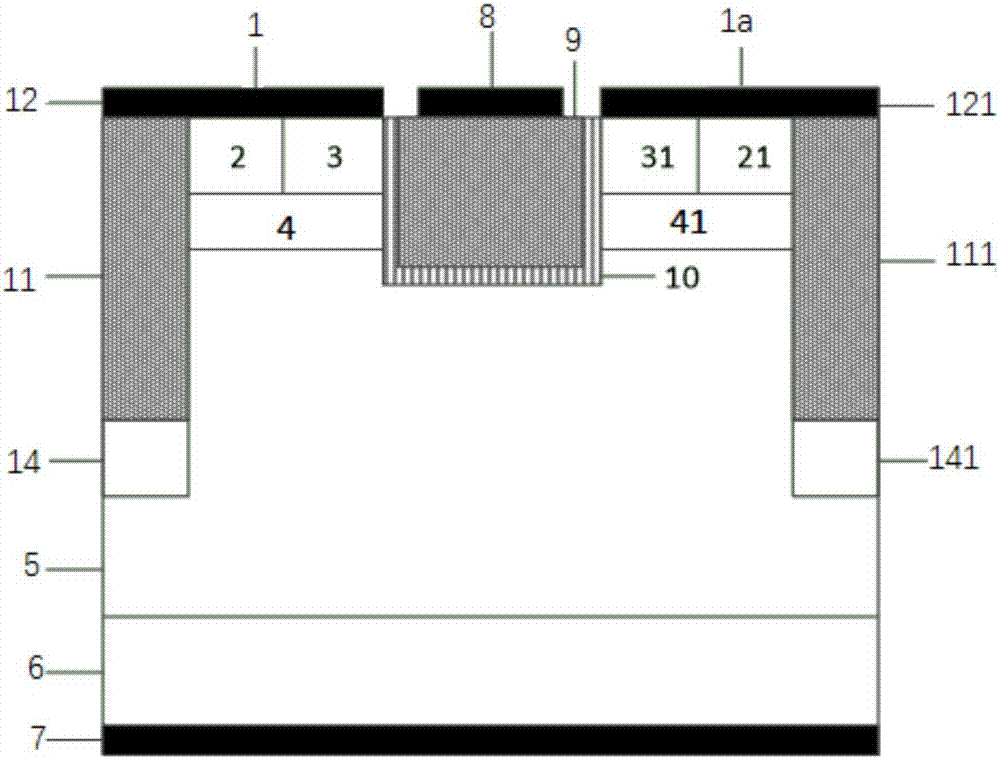

[0105] This implementation except in the first P + polysilicon region 11 and the second P + There is a first P in contact with the polysilicon region 111 below + SiC region 14 and the second P + SiC region 141; the P + The width of the silicon carbide region 14, 141 is greater than P + The width of the polysilicon region 11, such as Figure 4 As shown, in this implementation P + The width of the silicon carbide regions 14 and 141 ranges from 1.0 to 2.6 μm.

[0106] In this example, P + The silicon carbide regions 14, 141 have larger lateral dimensions (i.e., widths), which have a stronger electric field shielding effect on the P+ polysilicon regions 11, 111 and trench gates compared to Example 2, further improving the withstand voltage of the device, and at the same time The reverse leakage current is also further suppressed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com