Heat-resistant circular air door

A damper and temperature-resistant technology, which is applied in the direction of lifting valves, valve details, engine components, etc., can solve the problems that cannot meet the detection requirements of air leakage and large air leakage, and achieve fast processing speed, low air leakage and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

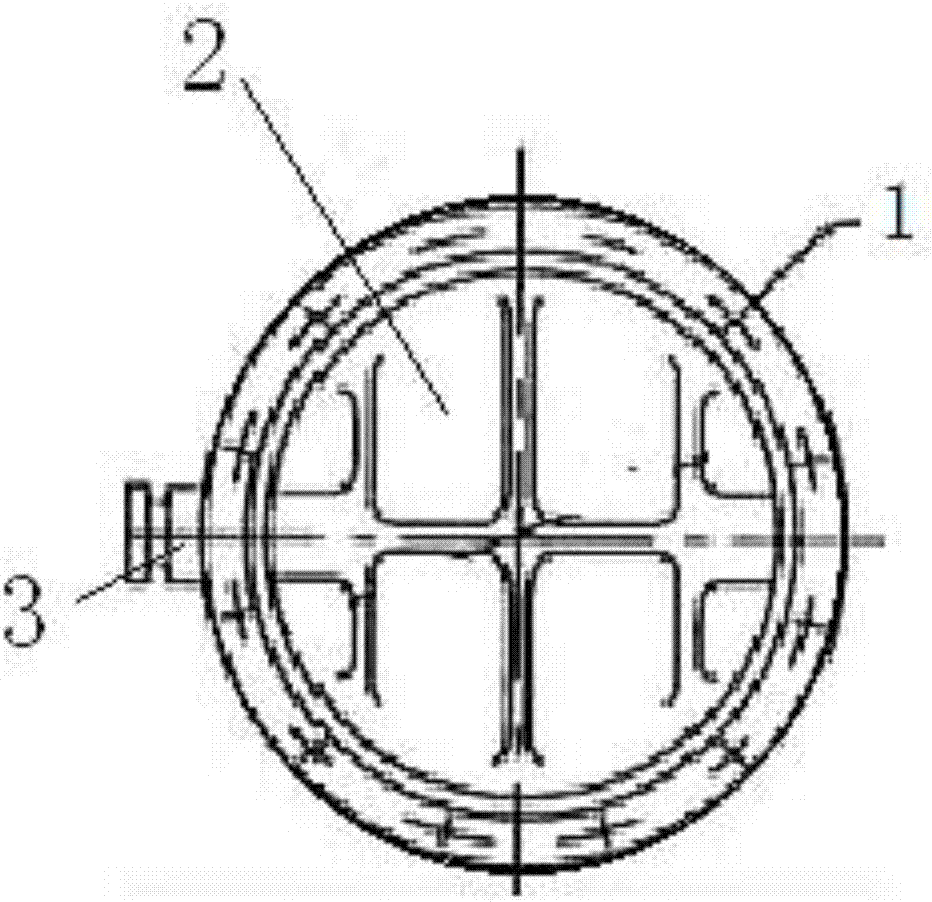

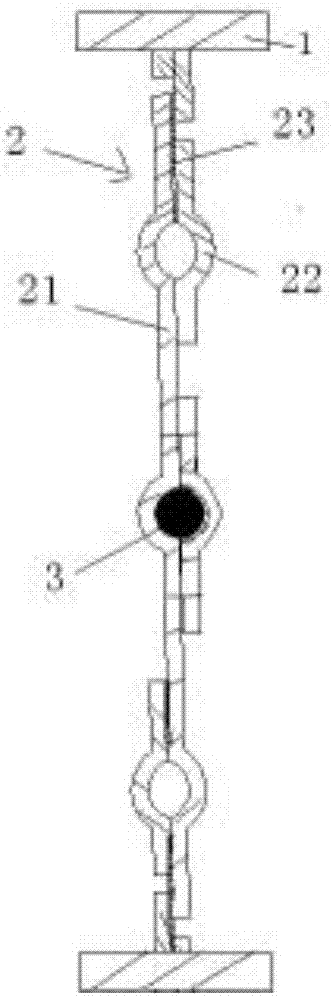

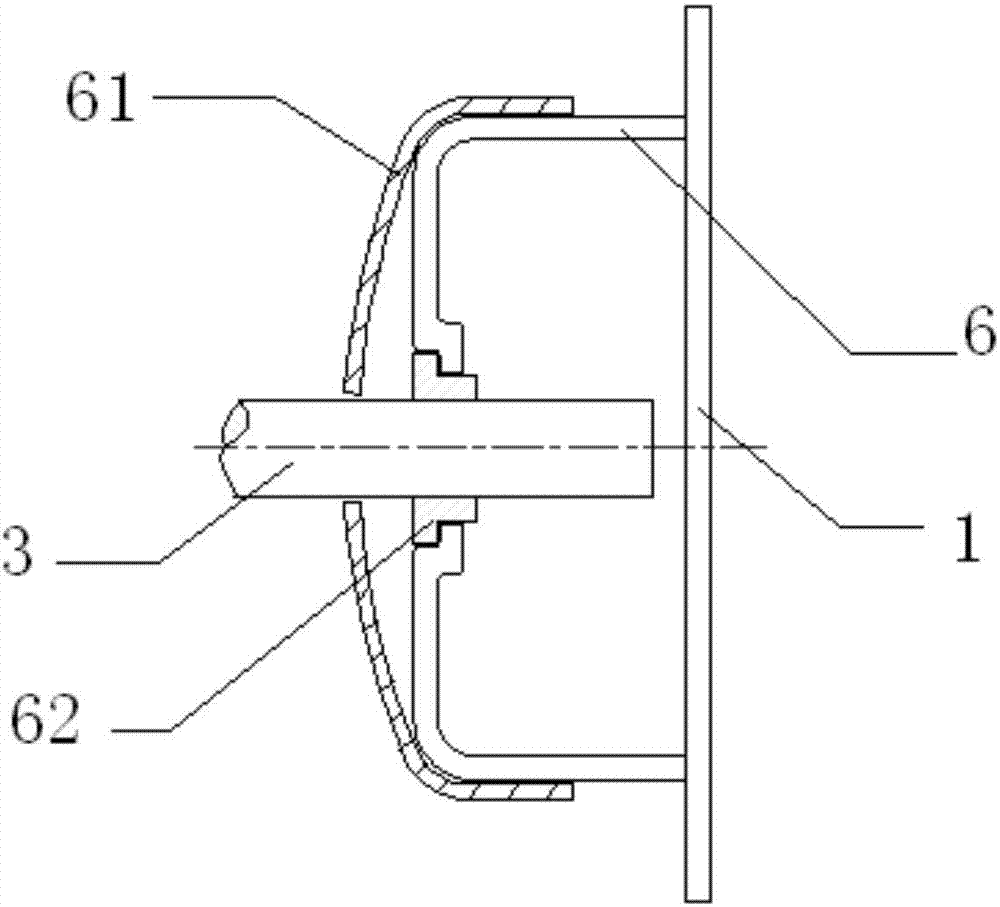

[0019] The present invention will be further described below in conjunction with the accompanying drawings. Among them, 1 is the door body, 2 is the blade, 21 is the first sub-blade, 22 is the second sub-blade, 23 is the first elastic seal, 3 is the rotating shaft, 6 is the blade bracket, 61 is the second elastic seal, 62 is a copper sleeve.

[0020] Such as Figure 1-3 As shown, a temperature-resistant round damper includes a door body 1, and more than one blade 2 is arranged in the door body 1 from top to bottom. In this embodiment, the number of blades is 3, and the middle blade is long. , with two right arcs and one left arc. And a right arc of the blade 2 is rotatable on the door body 1 through the rotating shaft 3, and the blades 2 are connected by the transmission of the linkage mechanism (wrapping the drive shaft) simultaneously; the blade 2 includes the first sub-blade and the second sub-blade, the first Arc-shaped structures are set on the sub-blades themselves, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com