Thermal radiation coating composition for automobile lamp and preparation method of thermal radiation coating composition

A technology of radiation heat dissipation and composition, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of anti-fog failure, flowing appearance, increasing the load of car lights, etc., and achieve the effects of low volatility, low environmental pollution, and easy coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

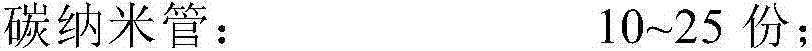

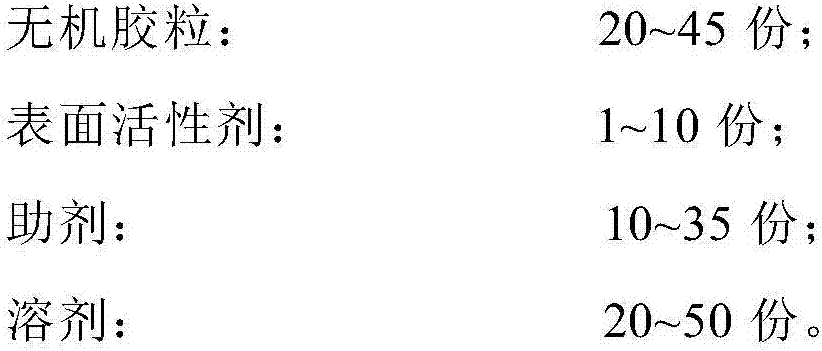

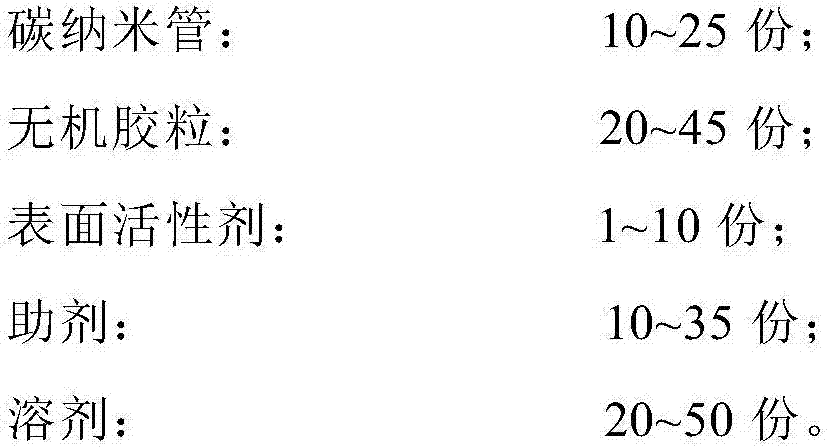

Method used

Image

Examples

Embodiment 1

[0036] 12 parts of multi-armed carbon nanotubes, 15 parts of montmorillonite with an average particle diameter of 75nm, 20 parts of spinel, 8 parts of surfactant (wetting and dispersing agent: defoamer: emulsifier: leveling agent=6:1.5 :2:0.5), 30 parts of deionized water, 15 parts of other additives (stabilizer:plasticizer=8:7). The average thickness of the coating after film formation is 10um, the temperature resistance is above 200°C, and the temperature drop is 20%. It can pass the PV1200 (20) cycle test.

Embodiment 2

[0038] 15 parts of multi-armed carbon nanotubes, 20 parts of illite with an average particle diameter of 75nm, 15 parts of spinel, 5 parts of surfactant (wetting and dispersing agent: defoamer: emulsifier=6:1.5:2.5), solvent 35 parts (deionized water: absolute ethanol = 5:1), 15 parts of other additives (stabilizer: plasticizer = 9:6). The average thickness of the coating after film formation is 13um, the temperature resistance is above 200°C, and the temperature drop is 25%. It can pass the PV1200 (20) cycle test.

Embodiment 3

[0040] 15 parts of multi-armed carbon nanotubes, 18 parts of montmorillonite with an average particle diameter of 100nm, 22 parts of spinel, 5 parts of surfactant (wetting and dispersing agent: defoamer: emulsifier=6:1.5:2.5), 25 parts of solvent (deionized water: absolute ethanol = 5:1), 15 parts of other additives (stabilizer: plasticizer = 9:6). The average thickness of the coating after film formation is 8um, the temperature resistance is above 200°C, and the temperature drop is 18%. It can pass the PV1200 (20) cycle test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com