Ester-based compound, composition containing same, method for preparing same, and resin composition containing same

一种树脂组合物、化合物的技术,应用在有机化学等方向,能够解决使用限制、相容性差、没有太多进展等问题,达到优异耐迁移性和耐挥发性、优异耐应力性、优异拉伸强度和伸长率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

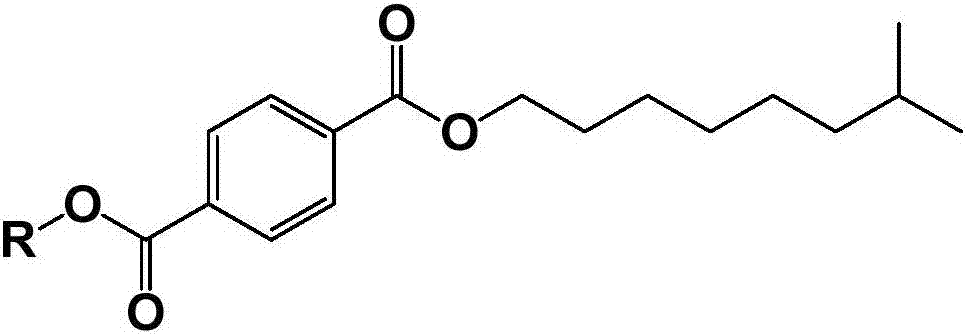

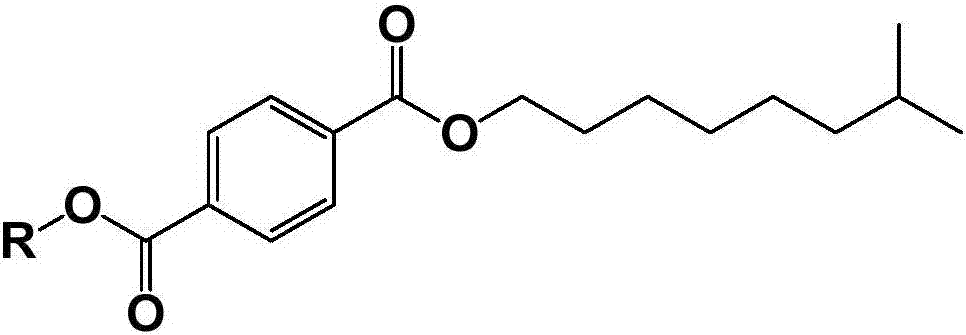

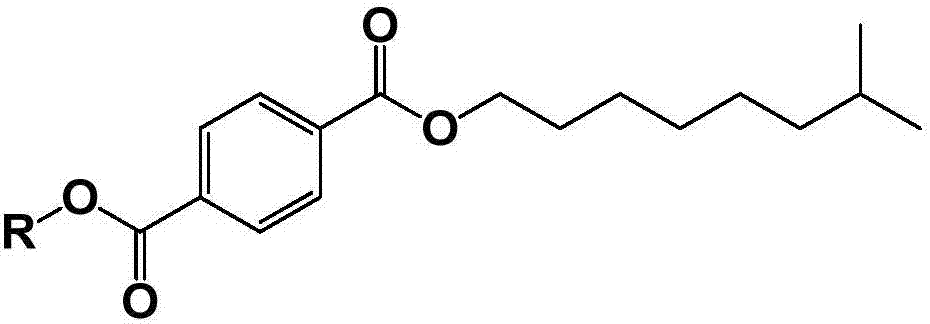

Image

Examples

preparation Embodiment 1

[0042] Preparation Example 1: Preparation of Diisononyl Terephthalate

[0043] Into a 4-neck 3-liter reactor equipped with cooler, water stripping unit, condenser, decanter, reflux pump, temperature controller, stirrer, etc., 498.4 g of purified terephthalic acid (PIA), 1172.1 g Isononanol (KH Neochem) (the molar ratio of terephthalic acid:isononanol is 1:3) and 1.54 g of a titanium-based catalyst (TIPT, tetraisopropyl titanate) as a catalyst (based on 100 parts by weight The terephthalic acid is 0.3 parts by weight), and the temperature is slowly raised to about 170°C. Water began to be generated around 170°C, and the ester reaction was carried out at a reaction temperature of about 220°C under atmospheric pressure for about 4.5 hours while continuously feeding nitrogen, and when the acid value reached 0.01, the reaction was stopped.

[0044] After stopping the reaction, extractive distillation under reduced pressure was carried out for 0.5 hours to 4 hours to remove unreact...

Embodiment 1

[0046] In the reactor that is provided with stirrer, condenser and decanter, add 2000g diisononyl terephthalate and 340g n-butanol (based on 100 parts by weight DINIP being 17 weight parts) obtained in Preparation Example 1 parts), and then the resultant was subjected to a transesterification reaction at a reaction temperature of 160° C. for 2 hours under a nitrogen atmosphere, thereby preparing An ester-based plasticizer composition of butyl isononyl ester (BINTP) and 61.0% by weight diisononyl terephthalate (DINTP).

[0047] The reaction product was mixed distillation to remove butanol and 2-ethylhexanol and prepare the final ester-based plasticizer composition.

Embodiment 2

[0049] In addition to using 2000 g of diisononyl terephthalate and 340 g of isobutanol to finally prepare 5.0 wt % of diisobutyl terephthalate, 37.0 wt % of Except for the ester-based plasticizer composition of diisononyl terephthalate, the transesterification reaction was performed in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com