Method and device for automatically observing fire in aluminum electrolytic cell

An aluminum electrolytic cell and automatic technology, applied in the field of aluminum electrolysis, can solve problems such as difficulty in popularization and in-depth study, lack of unified standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

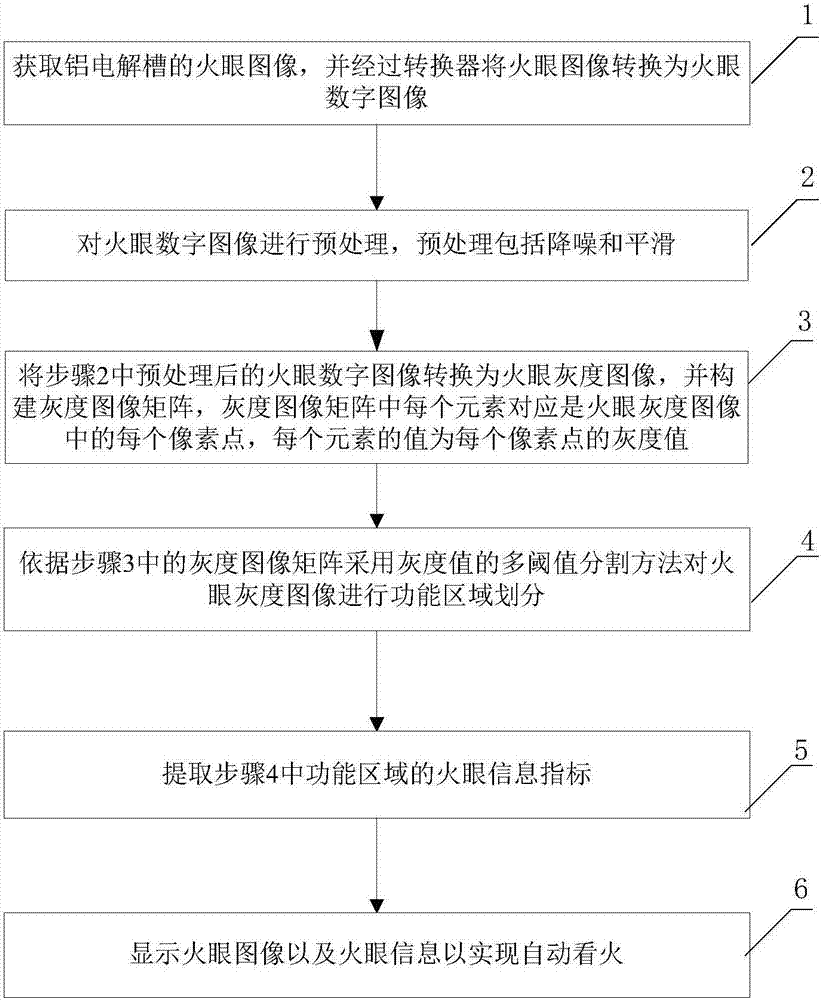

[0088] like figure 1 As shown, a method for automatically checking the fire of an aluminum electrolytic cell provided in an embodiment of the present invention includes:

[0089] Step 1: Obtain the fire eye image of the aluminum electrolytic cell, and convert the fire eye image into a fire eye digital image through a converter.

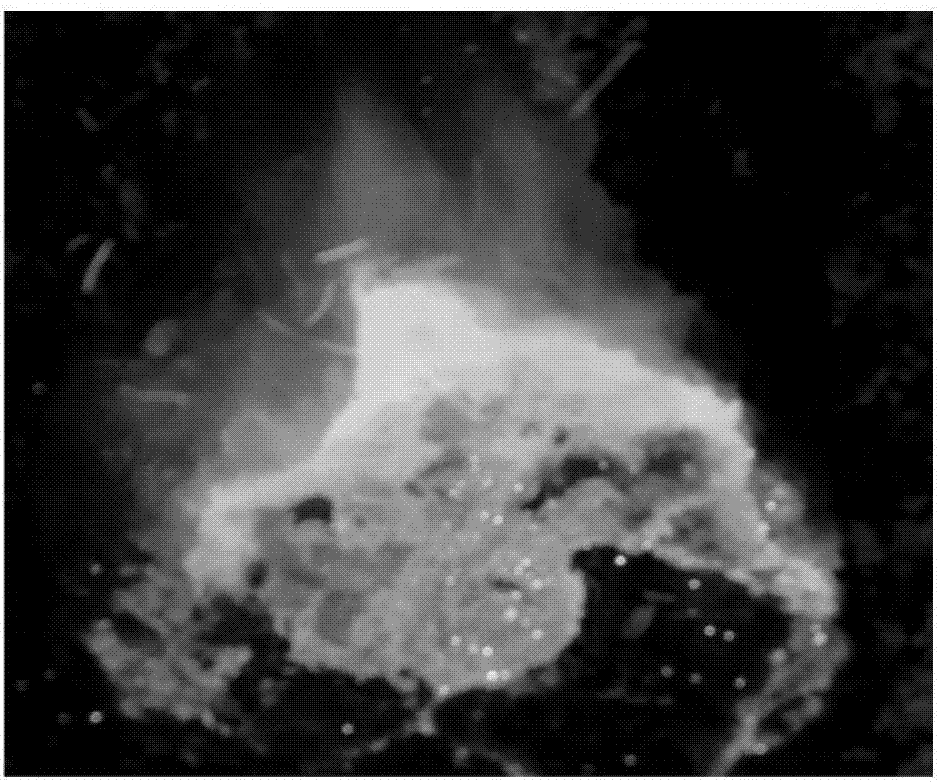

[0090] like figure 2 As shown, in this embodiment, the image of the fire eye of the aluminum electrolytic cell is collected by the image acquisition sensor.

[0091] Step 2: Preprocess the Huoyan digital image, including noise reduction and smoothing.

[0092] Specifically, the image is cleaned to eliminate the influence of sampling noise.

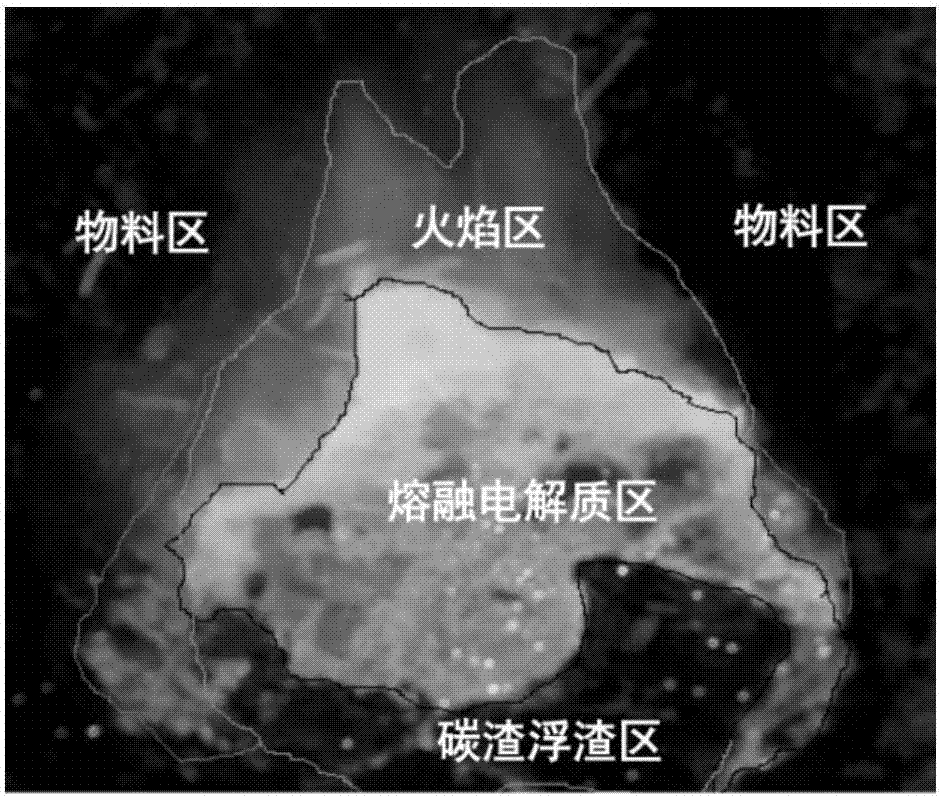

[0093] Step 3: Convert the Huoyan digital image preprocessed in step 2 into a Huoyan grayscale image, and construct a grayscale image matrix;

[0094] Each element in the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com