Concrete doped with quartz stone artificial stone waste residues

A technology of artificial stone and quartz stone, which is applied in the fields of concrete doped with artificial stone waste residue of quartz stone and structural materials for construction, can solve the problems of water body and air pollution, multiple land resources, etc., and achieve ecological benefits, reduce segregation, reduce The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

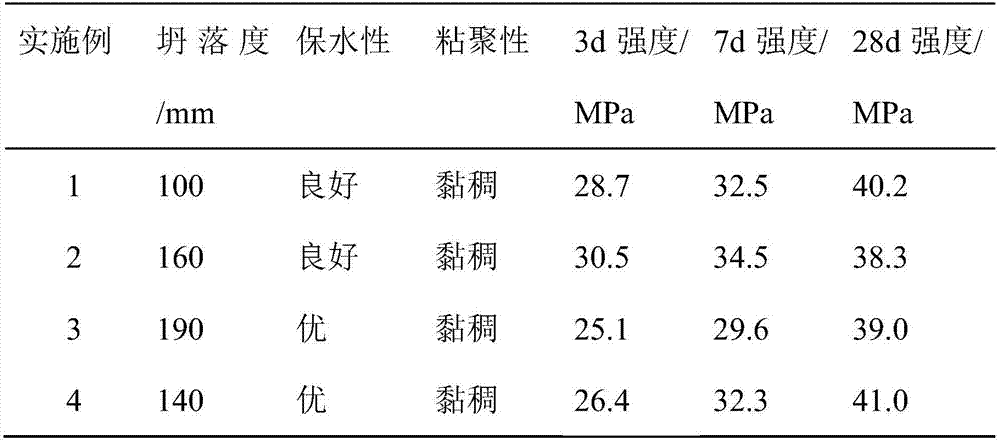

Examples

Embodiment 1

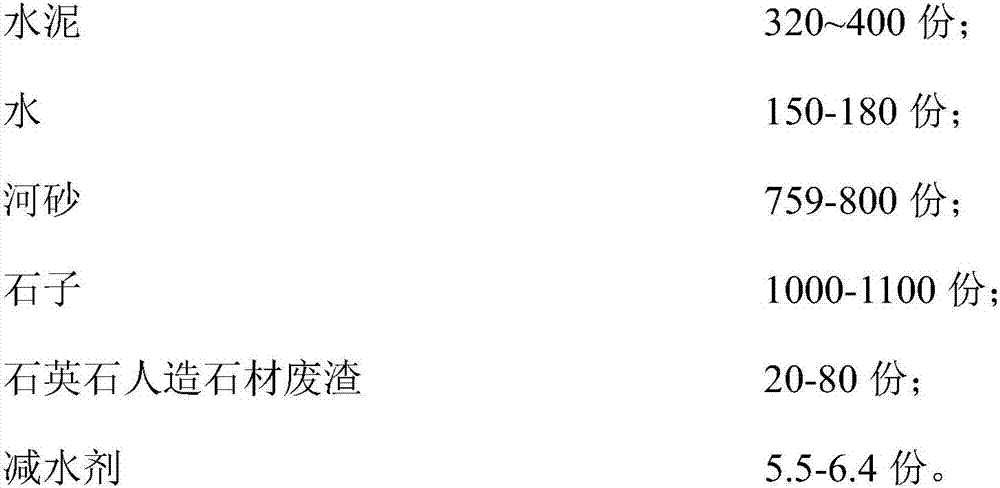

[0023] Concrete mixed with quartz artificial stone slag, according to the mass ratio, includes the following raw material components:

[0024] Cement: Quartz Stone Artificial Stone Waste: Water: River Sand: Stone: Water Reducer = 360:40:160:773:1067:6.2;

[0025] The cement is P.Ⅱ42.5 cement, and all indicators meet the relevant regulations in "General Portland Cement";

[0026] Quartz stone artificial stone waste residue is the powdery material obtained from the waste residue produced during the production process of polyester quartz stone artificial stone, which is dried at 105 ° C and ball milled for 30 minutes by a ball mill; the specific surface area of quartz stone artificial stone waste residue is 300m 2 / kg, the apparent density is 1960kg / m 3 , the loose bulk density is 700kg / m 3 , the porosity is 64%, and the close packing density is 810kg / m 3 , porosity 62%, SiO 2 The content is 88%;

[0027] The water is tap water, and all indicators meet the relevant regulat...

Embodiment 2

[0035] Concrete mixed with quartz artificial stone slag, according to the mass ratio, includes the following raw material components:

[0036] Cement: Quartz Stone Artificial Stone Waste: Water: River Sand: Stone: Water Reducer = 365:47:170:759:1049:6.1;

[0037] The cement is P.Ⅱ42.5 cement, and all indicators meet the relevant regulations in "General Portland Cement";

[0038] Quartz stone artificial stone waste residue is the powdery material obtained from the waste residue produced during the production process of polyester quartz stone artificial stone, which is dried at 105 ° C and ball milled for 25 minutes by a ball mill; the specific surface area of quartz stone artificial stone waste residue is 330m 2 / kg, the apparent density is 1990kg / m 3 , the loose bulk density is 730kg / m 3 , the loose void ratio is 58%, and the close packing density is 880kg / m 3 , with a tight porosity of 52%, SiO 2 The content is 87%;

[0039] The water is tap water, and all indicators m...

Embodiment 3

[0047] Concrete mixed with quartz artificial stone slag, according to the mass ratio, includes the following raw material components:

[0048] Cement: Quartz Stone Artificial Stone Waste: Water: River Sand: Stone: Water Reducer = 350:80:152:785:1083:5.7;

[0049] The cement is P.Ⅱ42.5 cement, and all indicators meet the relevant regulations in "General Portland Cement";

[0050] Quartz stone artificial stone waste residue is the powdery material obtained from the waste residue produced during the production process of polyester quartz stone artificial stone, which is dried at 105 ° C and ball milled for 30 minutes by a ball mill; the specific surface area of quartz stone artificial stone waste residue is 380m 2 / kg, the apparent density is 1930kg / m 3, the loose bulk density is 700kg / m 3 , the loose void ratio is 64%, and the close packing density is 840kg / m 3 , with a tight porosity of 55%, SiO 2 The content is 88%;

[0051] The water is tap water, and all indicators me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com