Carbon rod filter assembly

A filter element and component technology, applied in the field of water purification equipment, can solve the problem that the carbon rod filter element is difficult to meet the requirements of the large flux of water purification in the whole house, and achieve excellent filtration state, good filtration effect, and increase the effect of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

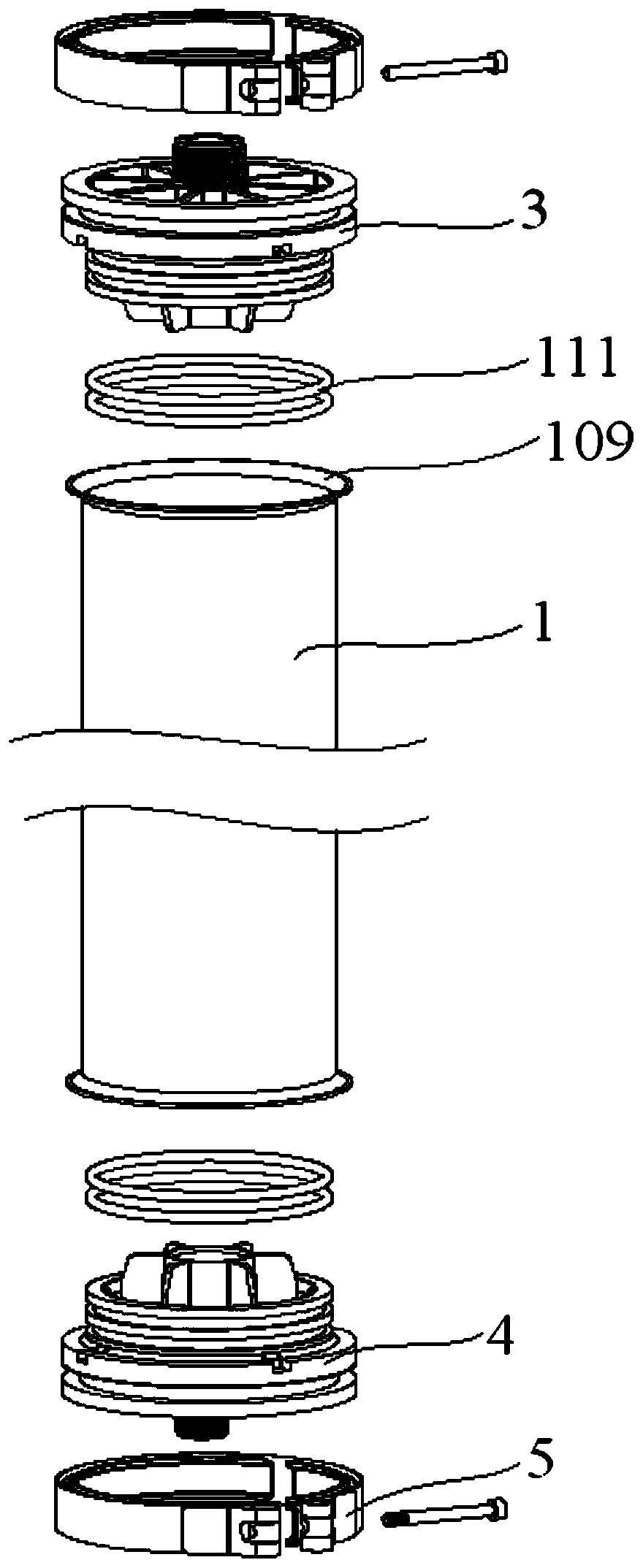

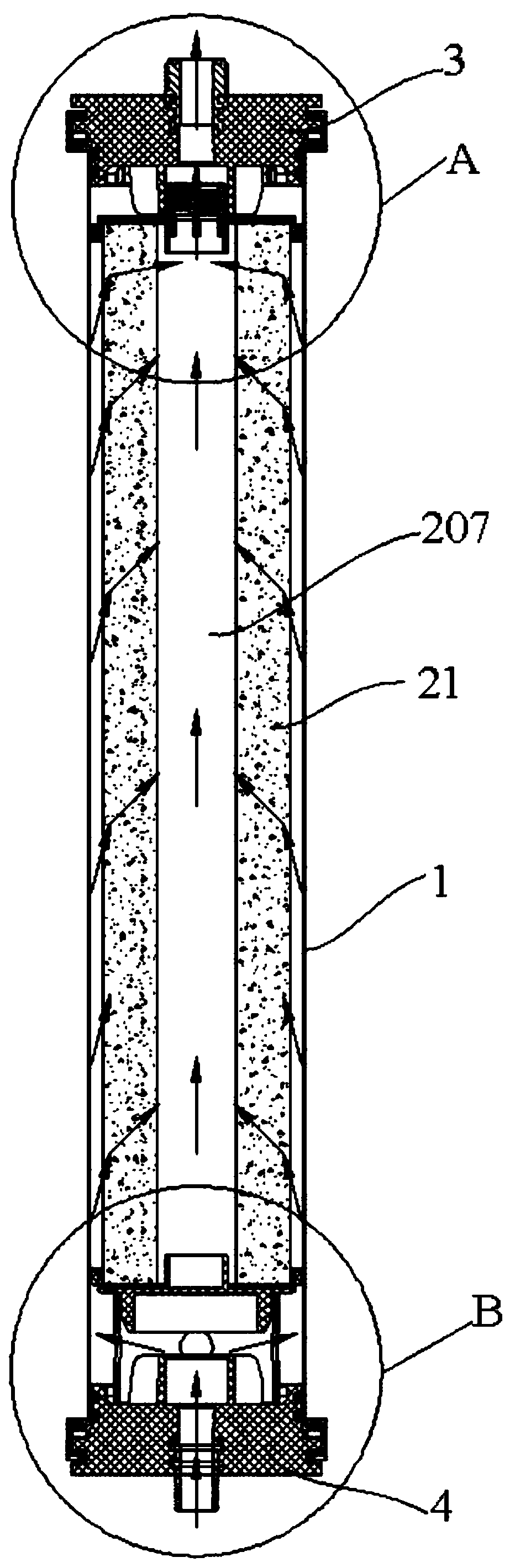

[0028] Carbon rod filter components, such as Figure 1-Figure 7 As shown, it includes a filter element cylinder 1 and a filter element assembly 2 arranged in the filter element cylinder 1. There is a water gap between the filter element assembly 2 and the filter element cylinder 1. The filter element assembly 2 includes a carbon rod filter element 21 and a The upper filter element end cover 201 and the lower filter element end cover 202 at the two ends of the rod filter element 21, and the carbon rod is bonded and fixed between the upper filter element end cover 201 and the lower filter element end cover 202 by hot melt adhesive.

[0029] The outer side wall of the upper filter element end cover 201 is provided with a plurality of evenly arranged support ribs 203, and in this embodiment, four support ribs 203 are distributed on the outer side wall, which can ensure that the carbon rod filter element 21 is centered, and at the same time, the upper The inner surface of the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com