An integrated processing method and equipment for superheated steam blanching and combined drying

A technology of superheated steam and processing method, applied in the direction of food drying, food heat treatment, heating preservation of fruits/vegetables, etc., can solve the problems of increasing the cost of processing production lines, secondary pollution of materials, chemical residues, etc., to reduce the risk of secondary pollution , The degradation loss is small, and the effect of improving the hygiene level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following examples are descriptive, not restrictive, and cannot limit the protection scope of the present invention.

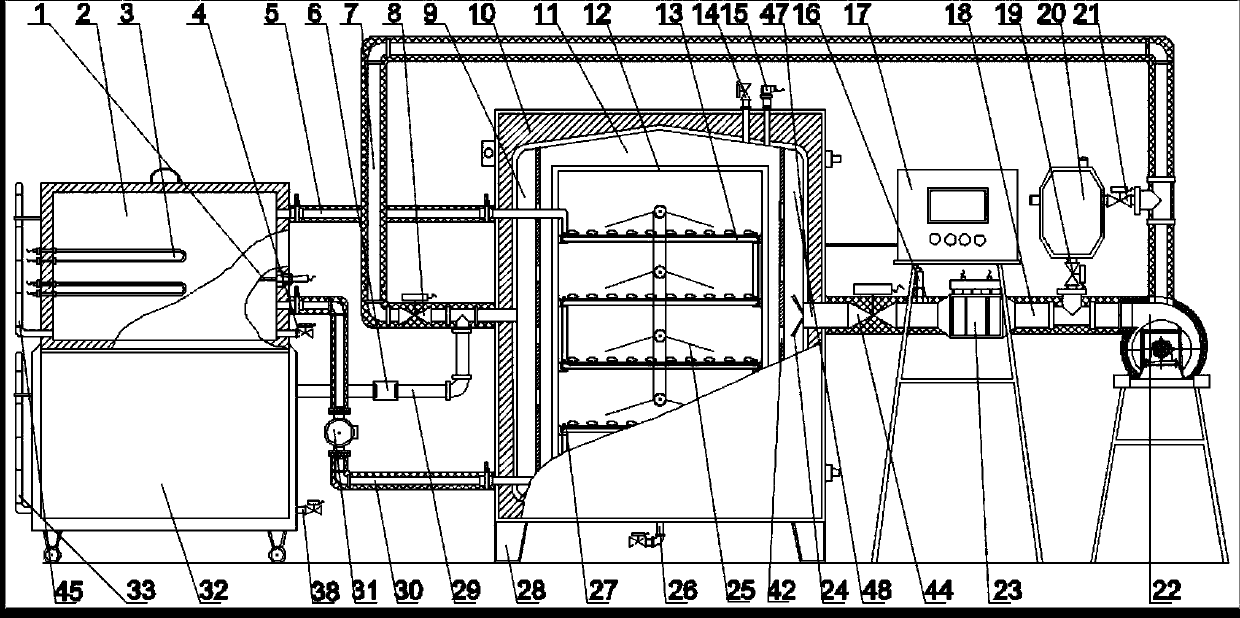

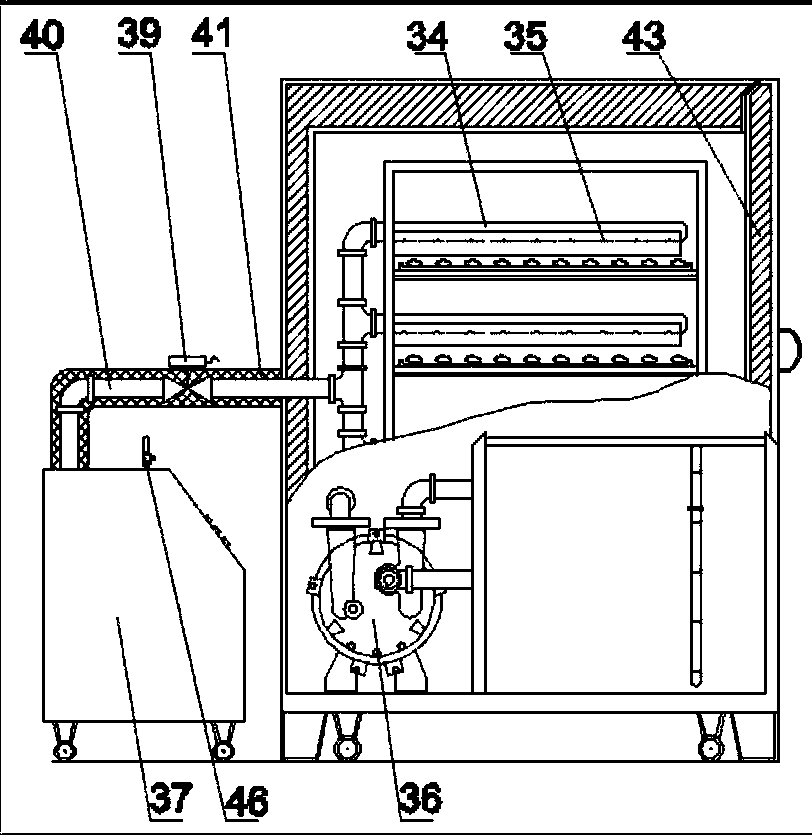

[0040] figure 1 It is a schematic structural diagram of a combined superheated steam blanching and hot air vacuum drying processing equipment, figure 2 It is a schematic left view of the device (parts 1, 2, 3, 4, 5, 6, 7, 8 and 45 are removed).

[0041] like figure 1 As shown, a superheated steam blanching and hot air vacuum combined drying processing equipment includes: an integrated combined processing body, a pressure pulsation generating system, a superheated steam blanching system, a hot air drying system, a vacuum drying heating system and an automatic control system.

[0042] Wherein: the integrated combined processing body includes a box body 11, a return air flow distribution chamber 9, an air intake air flow distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com