Shrub pruning machine

A technology of pruning machines and shrubs, which is applied in hedge trimming equipment, agricultural machinery and implements, gardening, etc., can solve the problems of high cost and low efficiency of shrubs, and achieve the effects of convenient construction, high scalability, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

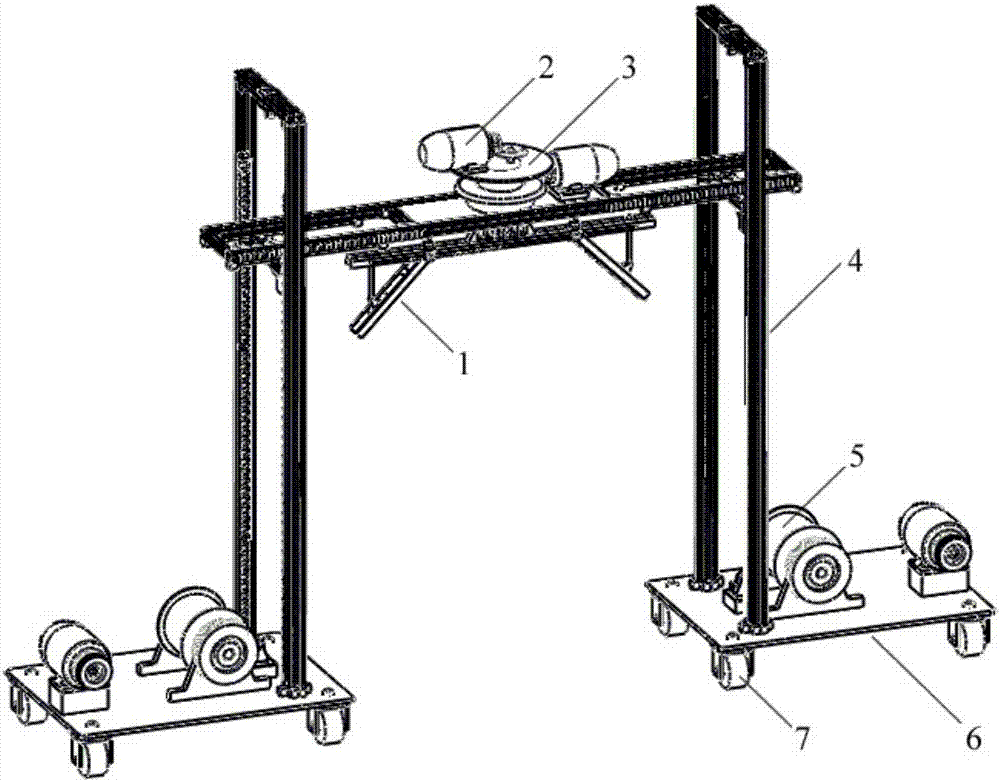

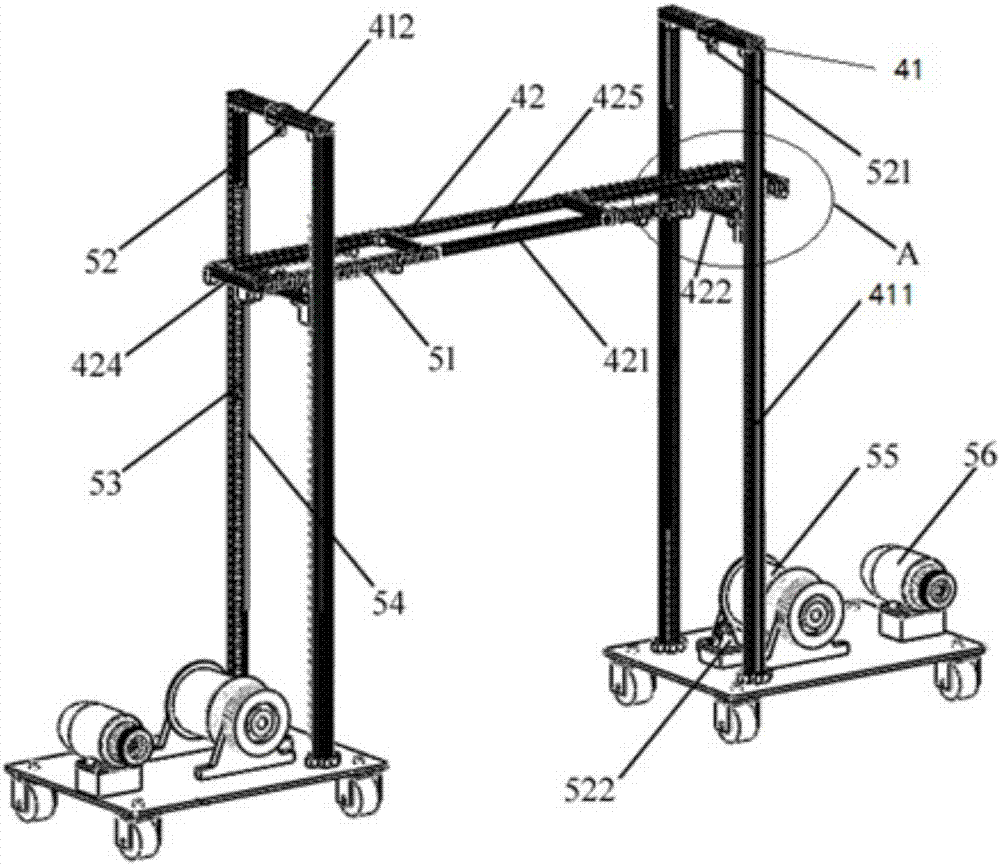

[0030] A shrub pruning machine in this embodiment comprises a base plate 6 on which a bracket 4 and a bracket adjusting device 5 are mounted; the bracket 4 is equipped with a pruning driving device 2 and a pruning transmission device 3; The trimming driving device 2 is connected with the trimming transmission device 3 ; the trimming transmission device 3 is connected with the trimming device 1 . The bracket 4 is a bracket built from standard aluminum alloy profiles through connecting corner fittings.

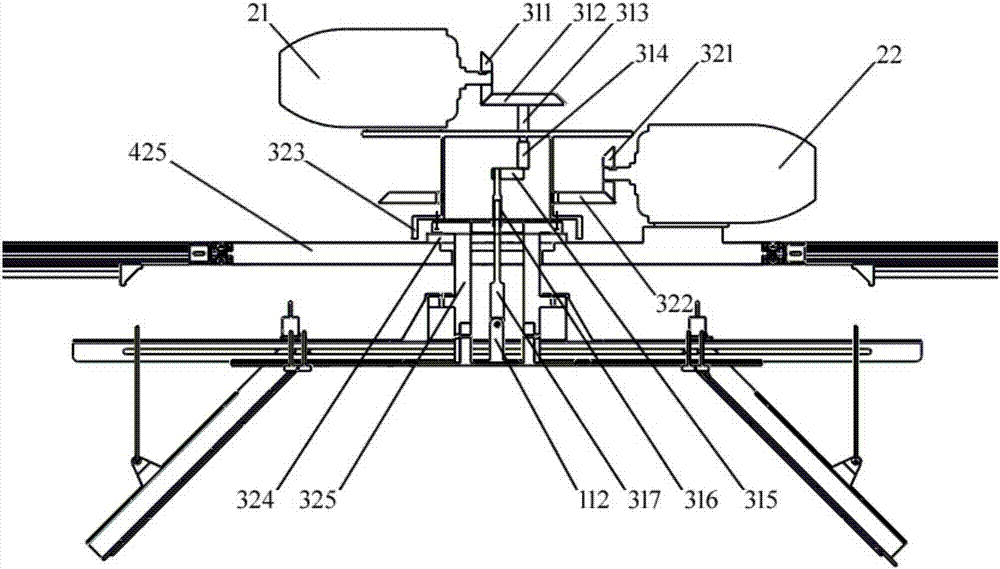

[0031] The trimming driving device 2 includes a first motor 21 for driving the cutter of the trimming device 1 to reciprocate and a second motor 22 for driving the trimming device 1 to rotate; 21 connected to the first bevel pinion gear 311, the second bevel gear 321 and the outer frame 323 connected to the second motor 22, wherein the first motor 21 is used to drive the offset crank linkage mechanism to reciprocate, so that The cutting tool of trimming device 1 also reciprocat...

Embodiment 2

[0041] A shrub pruning machine in this embodiment comprises a base plate 6 on which a bracket 4 and a bracket adjusting device 5 are mounted; the bracket 4 is equipped with a pruning driving device 2 and a pruning transmission device 3; The trimming driving device 2 is connected with the trimming transmission device 3 ; the trimming transmission device 3 is connected with the trimming device 1 . The bracket 4 is a bracket built from standard aluminum alloy profiles through connecting corner fittings.

[0042] The trimming driving device 2 includes a first motor 21 for driving the cutter of the trimming device 1 to reciprocate and a second motor 22 for driving the trimming device 1 to rotate; 21 connected to the first bevel pinion gear 311, the second bevel gear 321 and the outer frame 323 connected to the second motor 22, wherein the first motor 21 is used to drive the offset crank linkage mechanism to reciprocate, so that The cutting tool of trimming device 1 also reciprocat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com