Large-sized air-inflating thin film light-shielding cover structure with expanded space

An inflatable film and hood technology, which is applied to optical and photographic filters, cameras, etc., can solve the problems of complex structure of the hood, large size of the hood, complex control system, etc., and achieve simple and stable structure and small size , the effect of reducing the complexity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be further described in detail below with reference to the drawings and embodiments, but it is not used as a basis for any restriction on the invention.

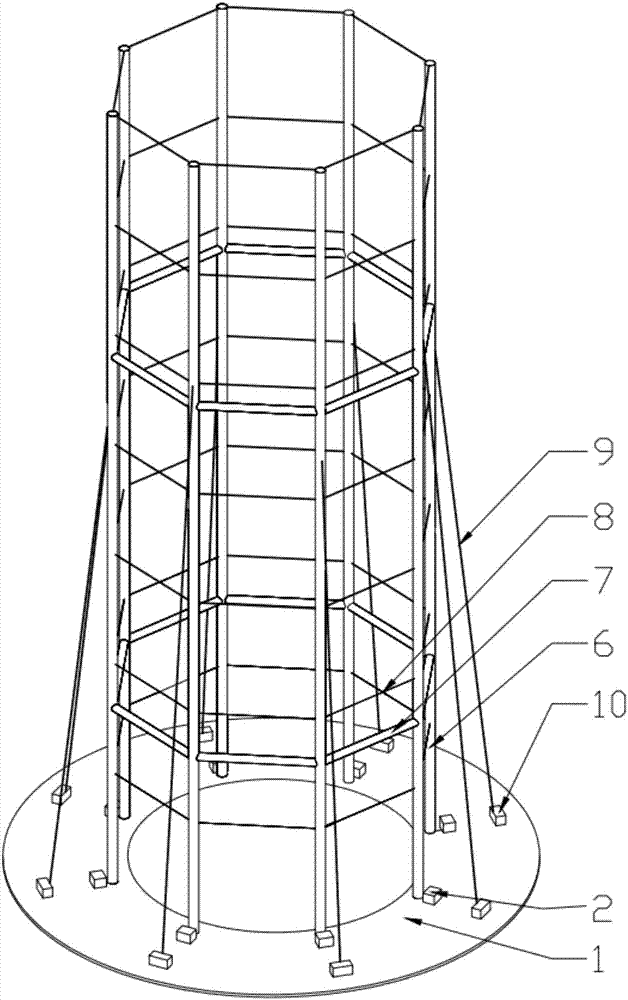

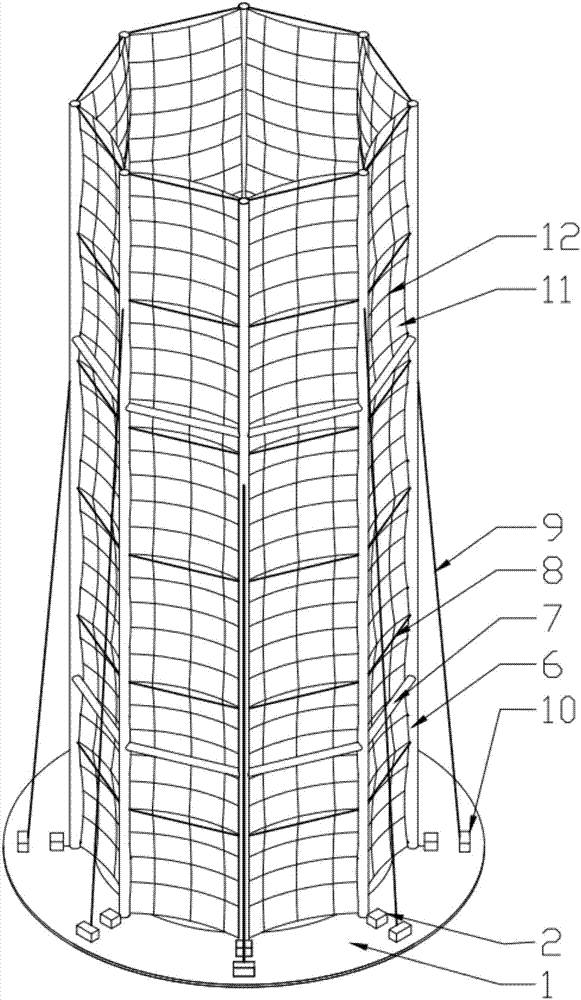

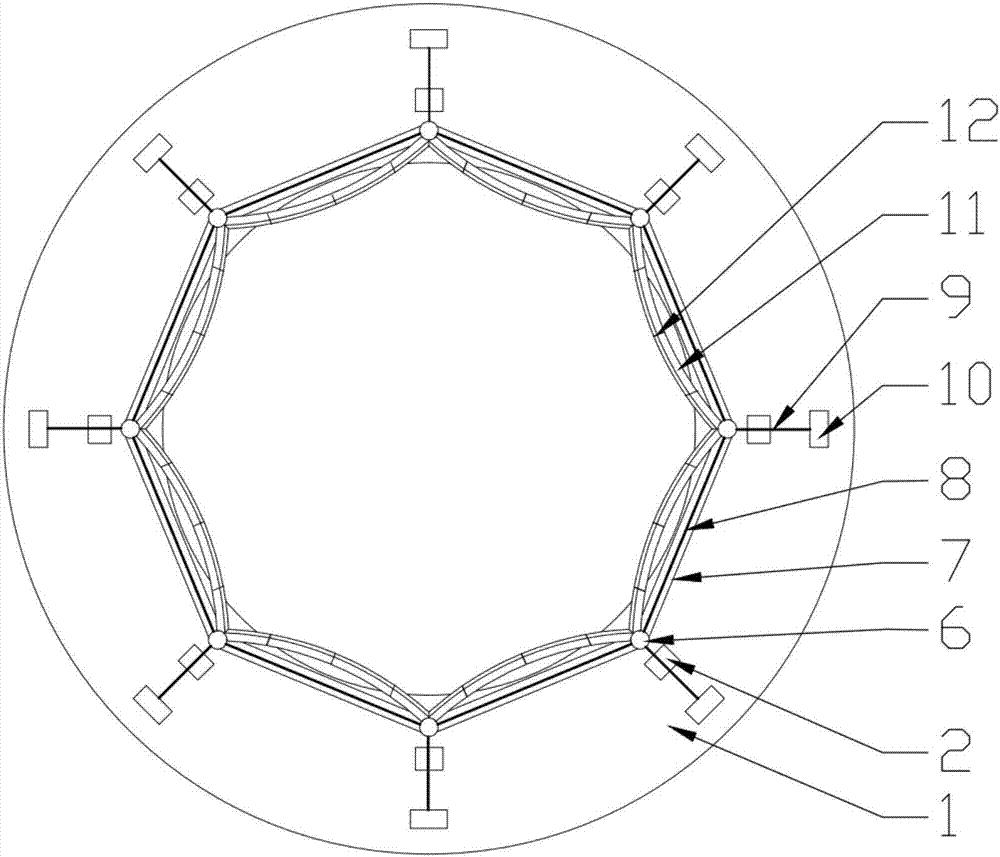

[0030] Figure 1 (a), Figure 1 (b), Figure 1 (c) and figure 2 As shown, a space-expandable large-scale inflatable film hood structure includes a hood base 1 fixedly connected to the base of the space camera, and a gathering tube 3 distributed along the circumference of the hood base 1. The gathering tube 3 is covered with The hood base 1 is fixedly connected to the inflatable tube frame for deployment and support of the hood, and also includes an adjustment cable-rod stretched on the surface of the inflatable tube frame for controlling the deployment of the inflatable tube frame, and bonded to the outside of the inflatable tube frame The shading film 11 is reinforced by the cable net 12 of the shading hood; an inflatable tank 2 corresponding to and communicating with the skeleton of the inflatable tube i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com