Method and device for diagnosing equipment status

A technology of equipment status and diagnostic methods, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve problems such as difficulty in ensuring the accuracy of status judgment results, and reduce the possibility of misjudgment and judgment credibility High, accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

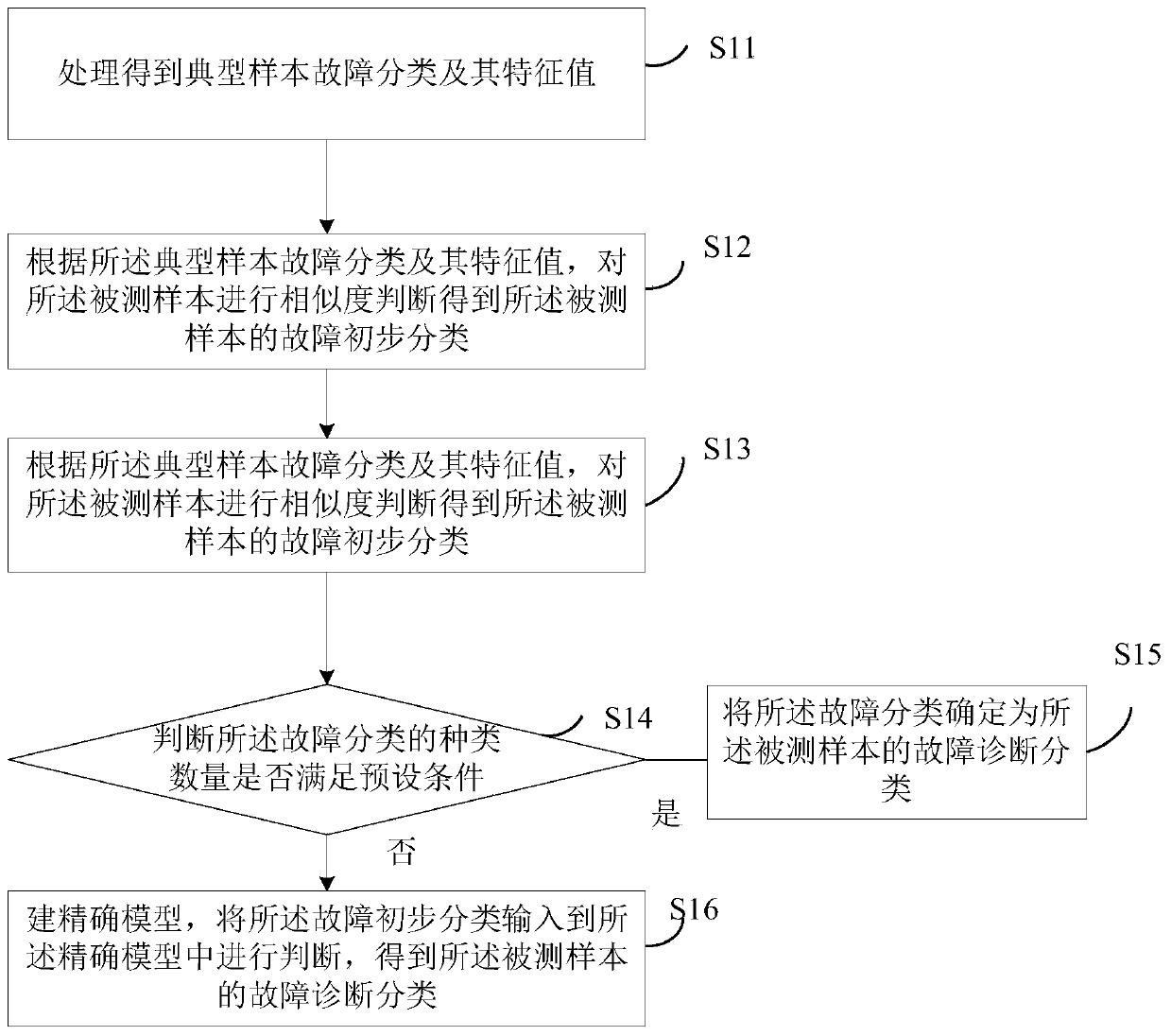

[0048] see figure 1 It is a schematic flowchart of a method for diagnosing equipment status provided by Embodiment 1 of the present invention, the method includes the following steps:

[0049] S11. Process the acquired historical samples to obtain typical sample fault classifications and their characteristic values, wherein the historical samples are equipment historical fault sample data;

[0050]Specifically, after obtaining the historical sample data in the historical sample database, statistical methods are used to initially classify and organize the sample data, and the K-nearest neighbor algorithm is usually used for induction to obtain typical sample fault classifications. The number of classifications is determined by The combination of manual judgment and historical data collation will gradually increase. For example, if the historical fault sample data of a steam turbine is obtained, the fault classification of typical samples can be divided into sudden unbalance of...

Embodiment 2

[0061] Referring to embodiment one of the present invention and figure 1 The specific process of steps S11 to S16 described in , and see figure 2 , the step S12 performs a similarity judgment on the tested sample according to the typical sample fault classification and its characteristic value to obtain a preliminary fault classification of the tested sample, which specifically includes the following steps:

[0062] S121. Determine a judgment condition for each fault classification according to the typical sample fault classification and its characteristic value;

[0063] S122. According to the judgment condition, perform parameter correlation analysis on the tested sample, and judge to obtain a preliminary fault classification of the tested sample.

[0064] Specifically, after the fault classification of typical samples is obtained, clear judgment conditions are summarized for different classification situations, and then parameter correlation analysis and classification ar...

Embodiment 3

[0079] Corresponding to the equipment diagnosis method disclosed in the first and second embodiments of the present invention, the third embodiment of the present invention also provides an equipment diagnosis device, see Figure 4 , the device consists of:

[0080] The processing module 1 is used to process the acquired historical samples to obtain typical sample fault classifications and their characteristic values, wherein the historical samples are equipment historical fault sample data;

[0081] The first judging module 2 is used to judge the similarity of the tested sample according to the typical sample fault classification and its characteristic value to obtain a preliminary fault classification of the tested sample;

[0082] The classification module 3 is used to obtain the sample feature value corresponding to the preliminary classification of the fault, perform weighted calculation on the sample feature value to obtain a similarity parameter, and determine the fault...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com