Grouting device and grouting method

A grouting device and grouting technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of inconvenient construction operation, poor economy, increased construction investment, etc., to facilitate construction installation and disassembly, and ensure uniform Continuity, the effect of improving the bearing capacity of single piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

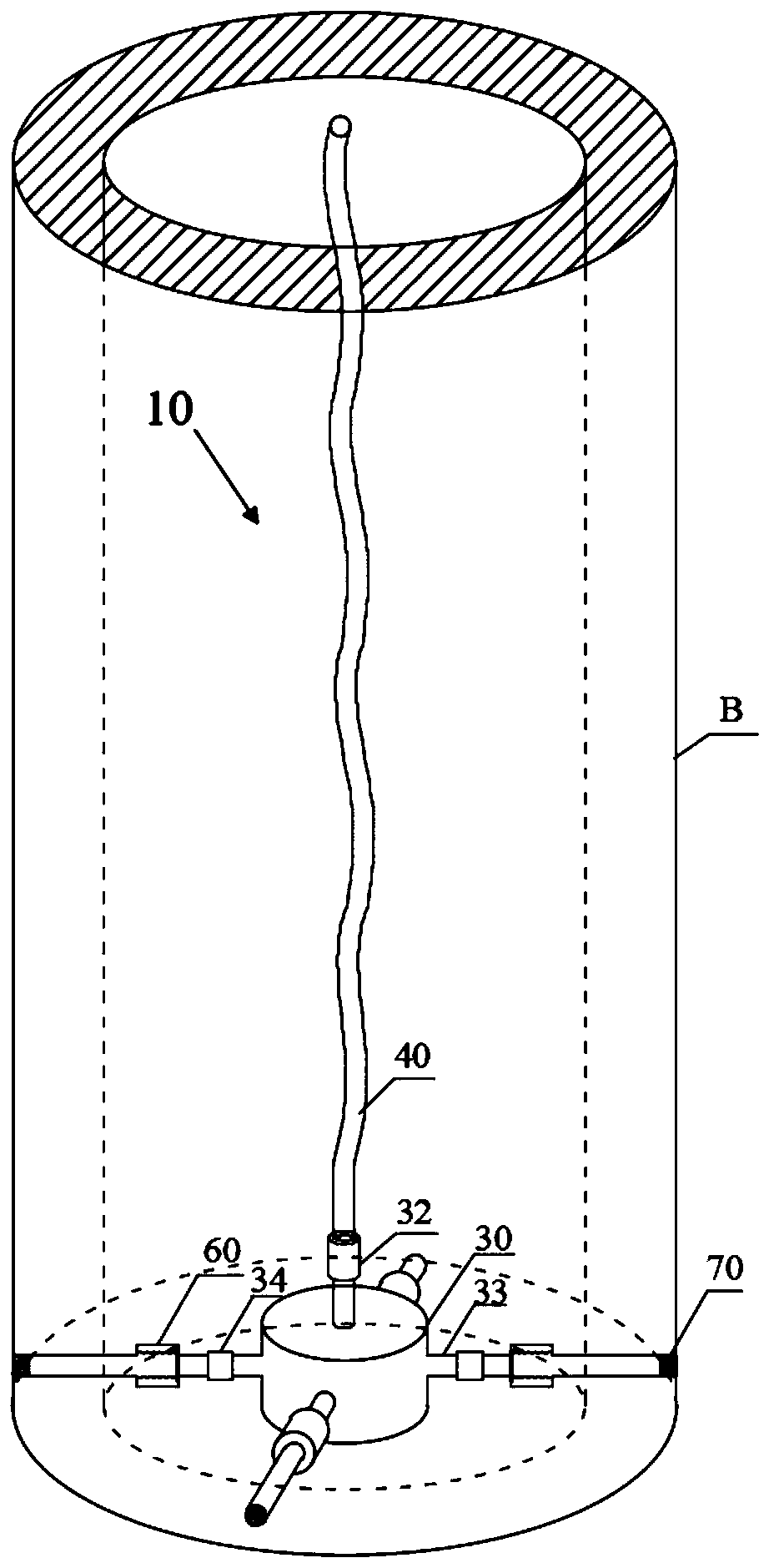

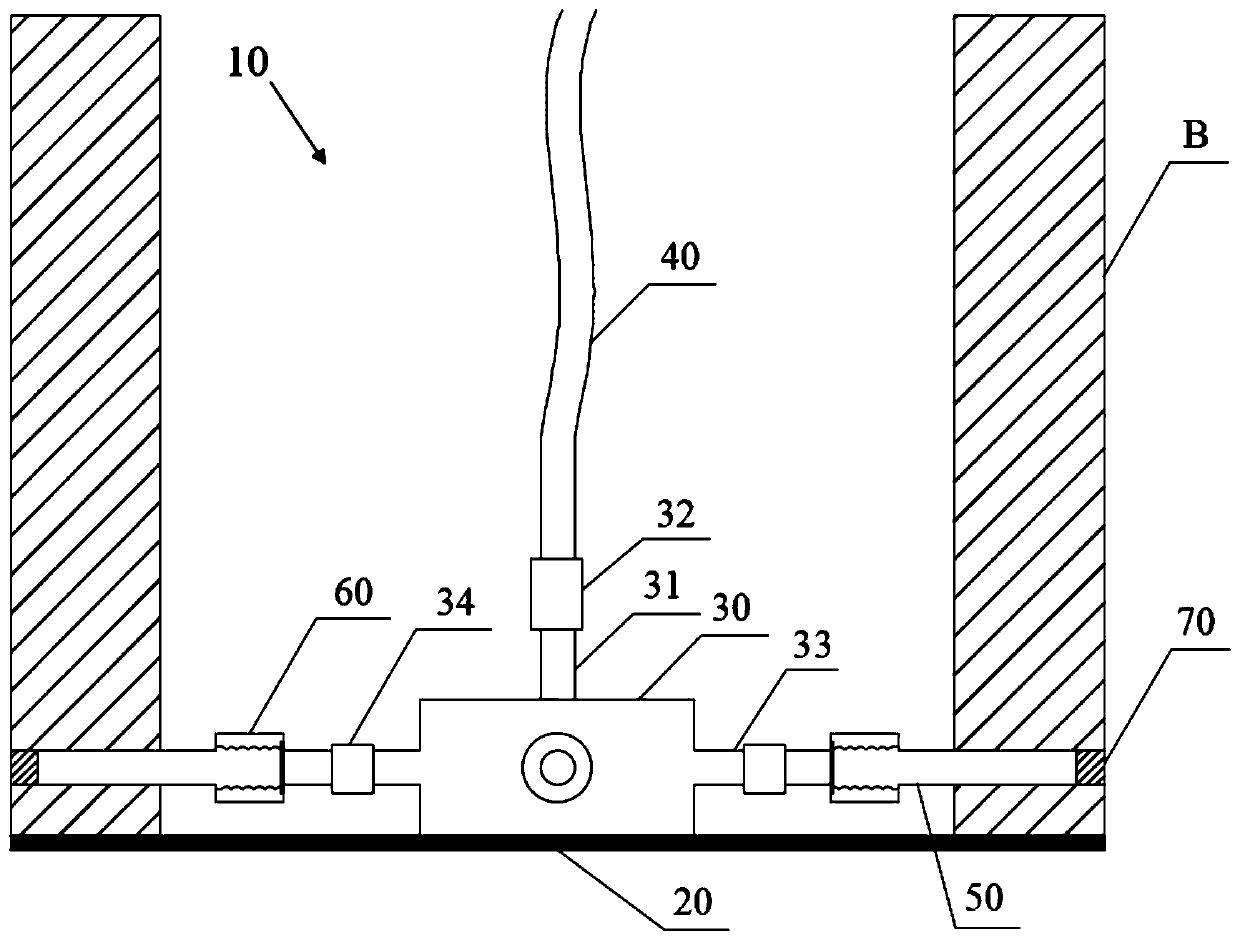

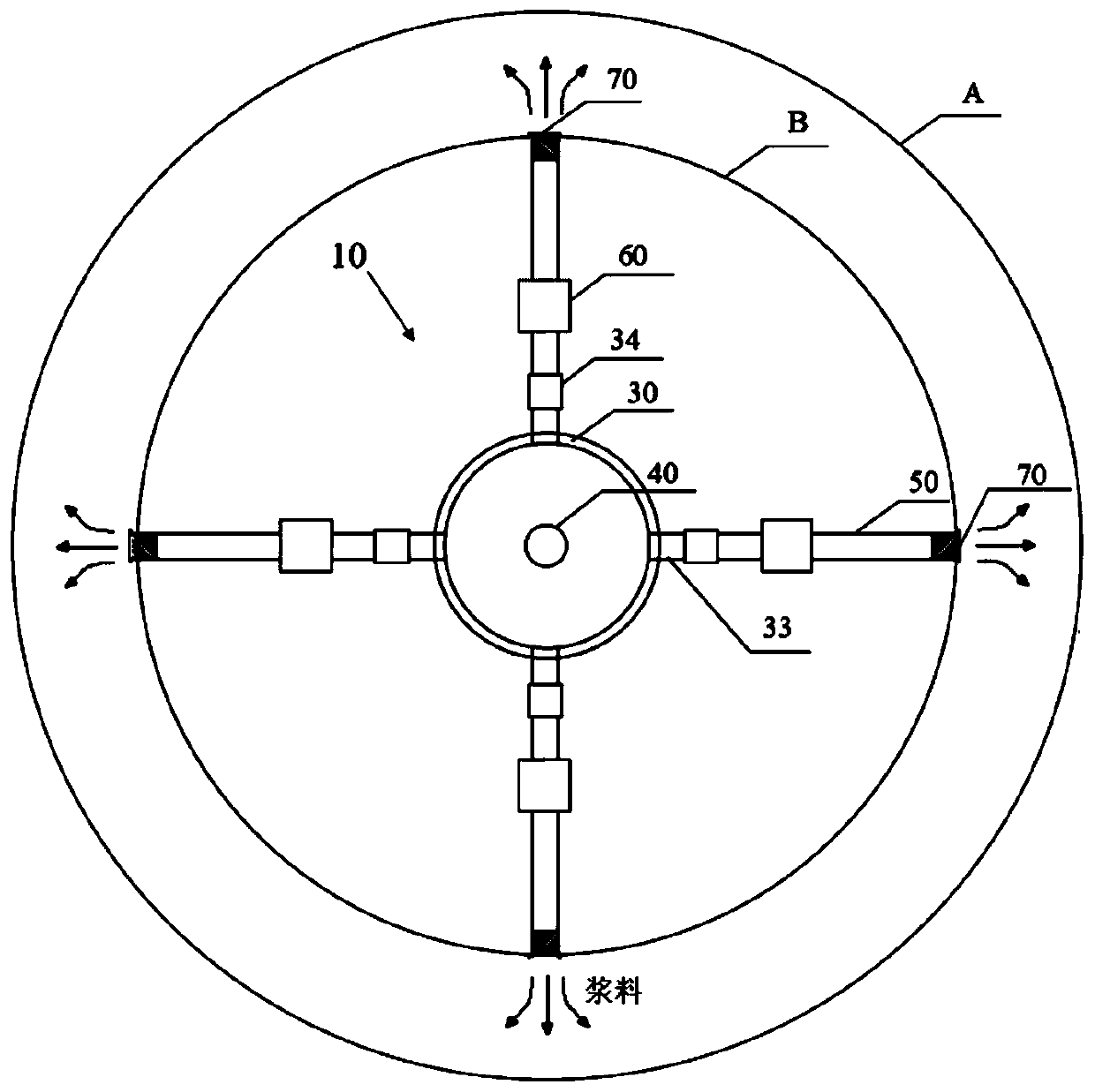

[0041] The grouting device and the grouting method involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0042]

[0043] Such as Figures 1 to 3 As shown, the grouting device 10 cooperates with the prefabricated pipe pile B, and is used for grouting after the prefabricated pipe pile is placed in the pile hole A with a diameter of 20 cm. It includes: an end plate 20, a grouting buffer chamber 30 , Grouting pipe 40, four outlet pipes 50, four check valves 60, and four plugs 70.

[0044] The end plate 20 is matched with the bottom end of the prefabricated pipe pile B, and is used to seal the bottom end of the prefabricated pipe pile B, so as to ensure that the inside and outside of the pile can be sealed and impermeable during the pile sinking and grouting process, and prevent the Cement slurry, water, soil, etc. enter the interior of the prefabricated pipe pile B. In this embodiment, the end plate 20 is The steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com