Fillable displacement adjustment compensation device

A technology of displacement adjustment and compensation device, applied in the direction of roads, buildings, ballast layers, etc., can solve the problem of lack of effective measures to completely cure, affecting the quality and safety of the project and the use time, etc., to save the amount of work and occupy a small space. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

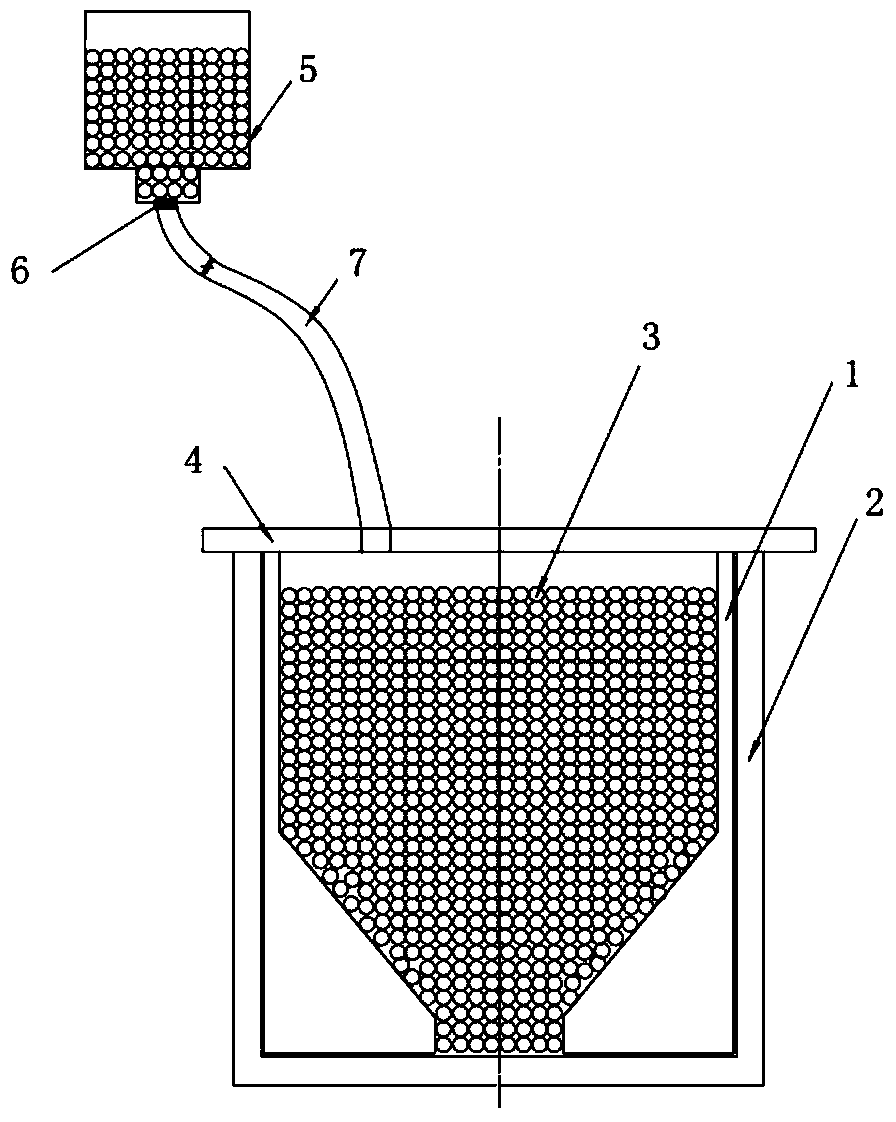

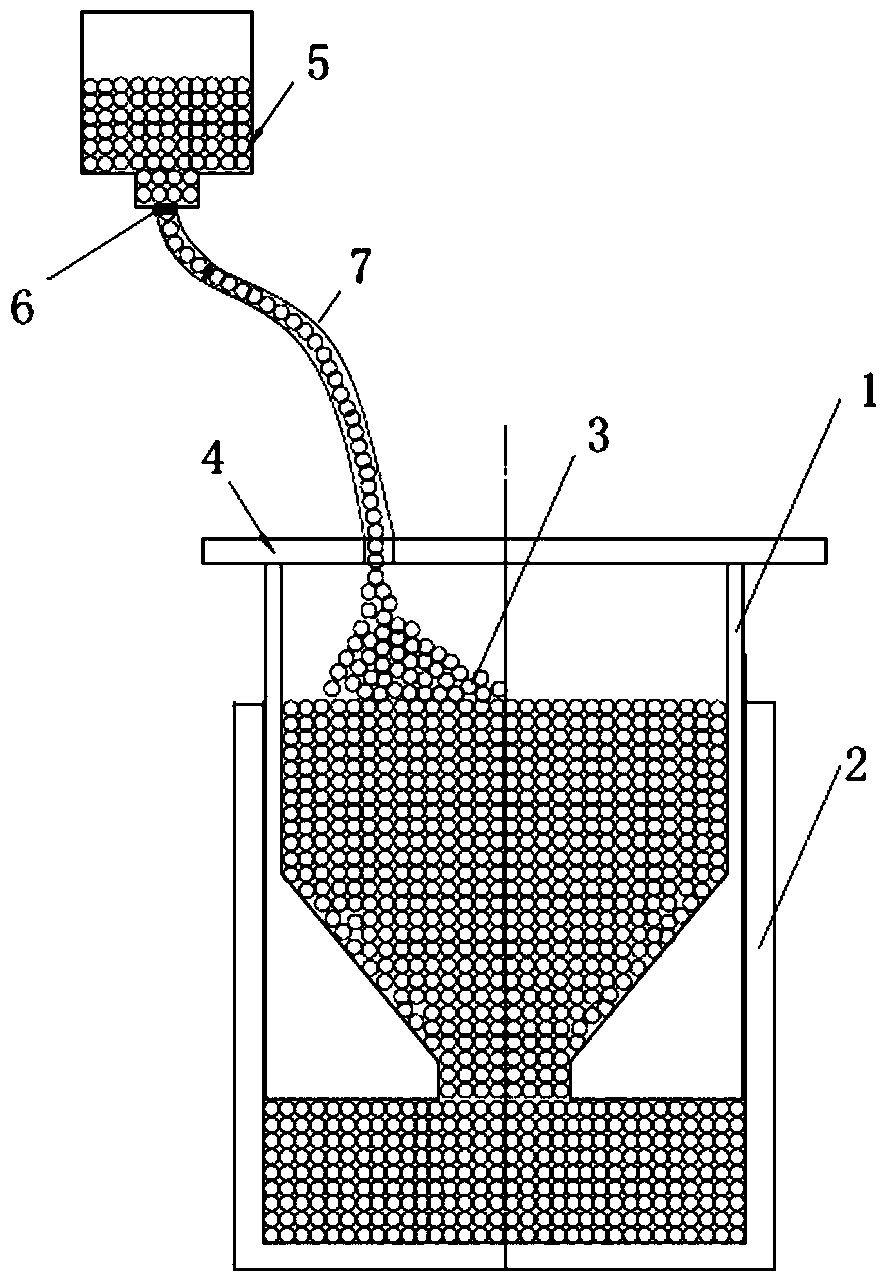

[0036] see figure 1 , shows the packing type displacement adjustment compensation device of the present invention, which is set between the foundation (foundation) and the supported objects (sleepers, bridge pillars, buildings, etc.) in use, specifically including the first support 2 and the second support Part 1, at least a part of the second supporting part 1 can be inserted into the opening formed by the first supporting part 2, and can relatively move axially.

[0037] The first support 2 is preferably a cylinder with a closed bottom, and the inside of the second support 1 is formed with a space for accommodating fillers. There is at least one opening on the bottom plate of the second support 1 for making the filler inside it Pass through and drop into the gap between the inner and outer sleeves. The top of the second supporting member 1 has an upper cover plate 4 for connecting with the supported object.

[0038] The packing type displacement adjustment compensation dev...

Embodiment 2

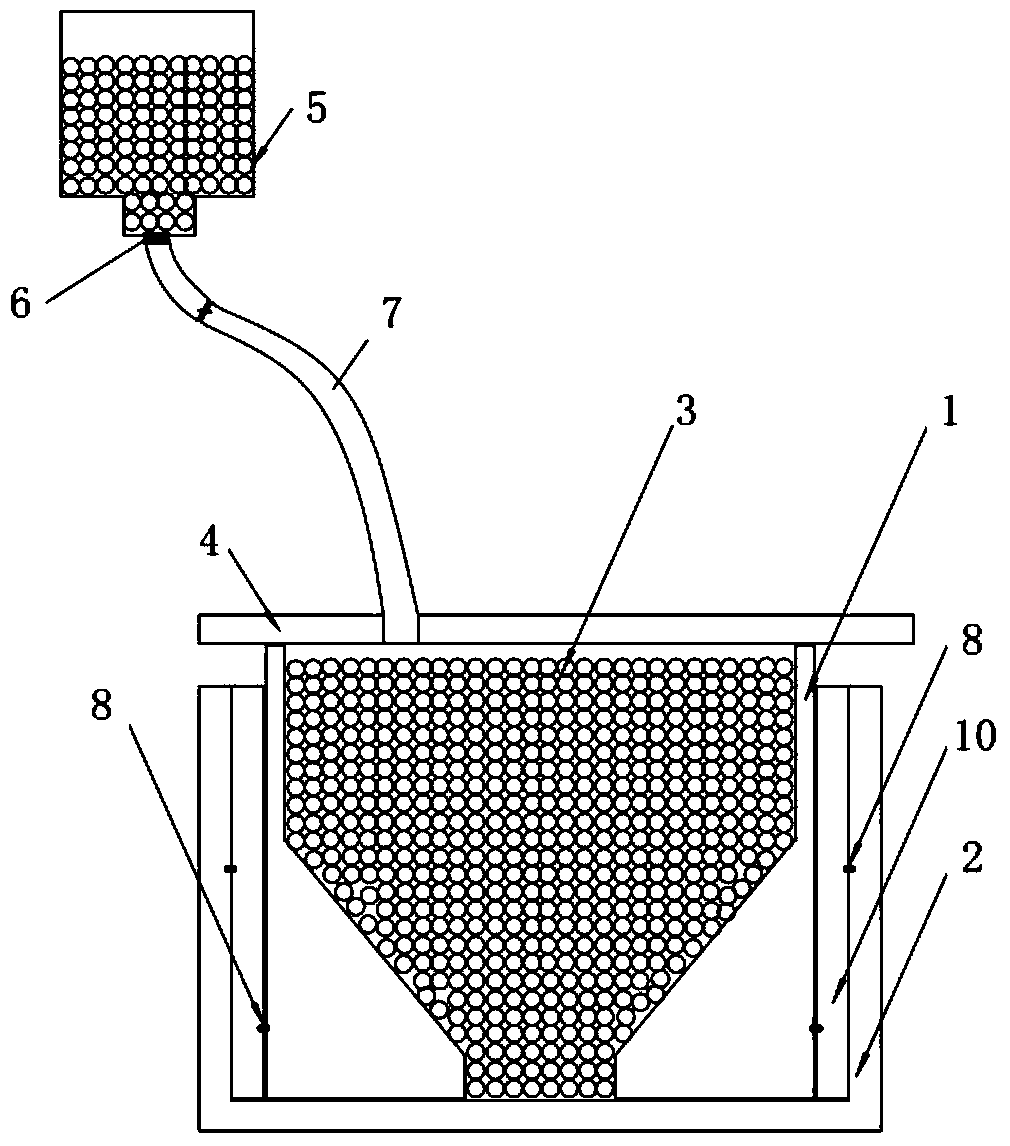

[0050] The structure of the first embodiment of the present invention is different from that of embodiment 1 in that a sleeve is added, and the height adjustment value of the multi-stage telescopic structure in embodiment 2 is larger, which can make full use of the advantage that the filling amount can be supplemented.

[0051] Specifically, there is at least one layer of sleeve 10 between the second support 1 and the first support 2 ( image 3 Take an intermediate sleeve as an example for illustration), wherein the second support member 1 and the first support member 2 are basically the same in structure as the second support member 1 and the first support member 2 in Embodiment 1 respectively, and the sleeve 10 There are openings at the top and bottom, and any two adjacent parts of the second support 1 , the multi-layer sleeve 10 and the first support 2 can move relative to each other along the axial direction, thereby realizing the height adjustment of the device.

[0052] ...

Embodiment 3

[0063] Figure 6-7 It shows the structural diagram of the third embodiment of the present invention, the second support 1 is in contact with the foundation, and the first support 2 is connected with the sleeper or other supported objects. There is no filler inside the second support member 1 . The first supporting member 2 is provided with an opening, and is connected with the stuffing box 5 outside through the opening.

[0064] A pressurizing mechanism is arranged inside the stuffing box 5 , such as a spring plate structure, etc., to apply pressure to the stuffing so that the stuffing can quickly flow into the first support member 2 of the cylinder.

[0065] In another solution, the second support 1 and the first support 2 can be turned upside down, that is, the first support 2 of the cylinder is in contact with the foundation, and the second support 1 is connected with the sleeper or other supported parts. At this time, the stuffing box 5 is also placed on the top, and com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com