Immobilizing device for producing immobilized enzyme or cells and immobilizing method thereof

A technology for immobilizing enzymes and immobilizing carriers, which is applied in the directions of biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc. Guaranteed biological activity, time shortening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

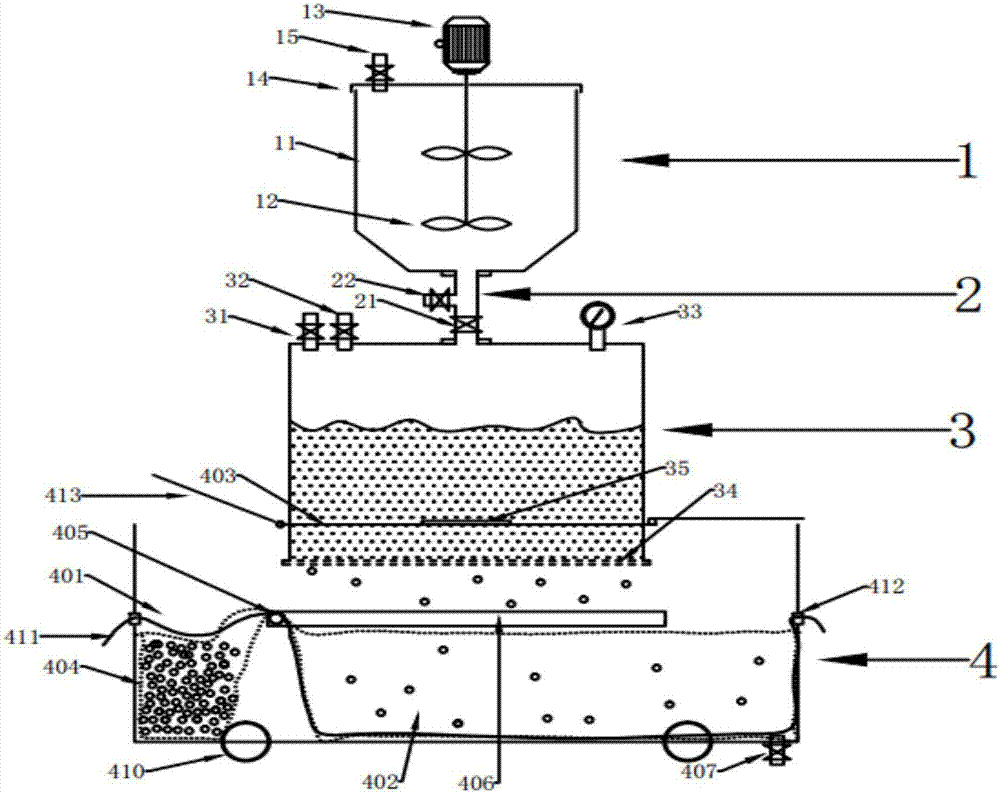

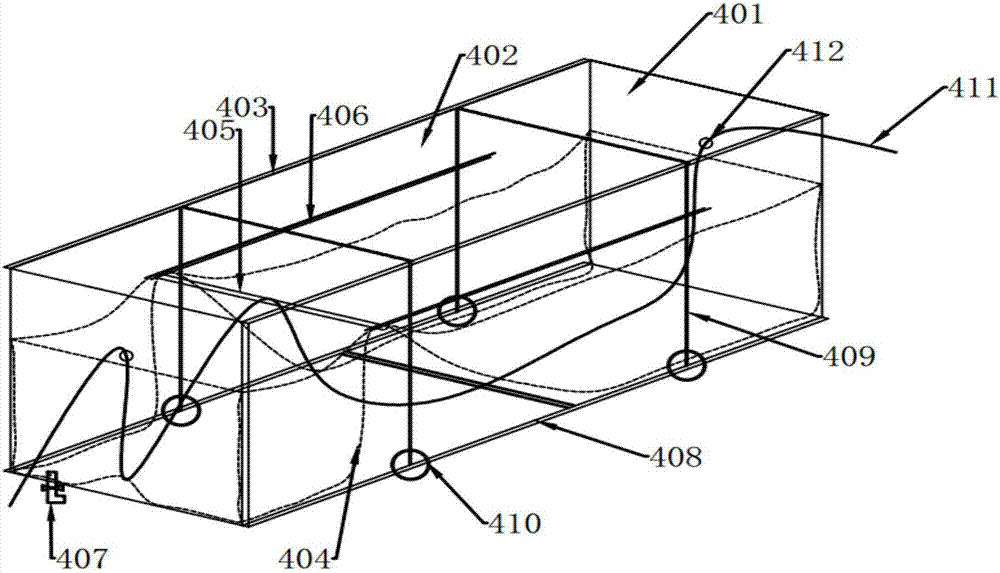

[0074] As introduced in the background technology, there are few studies on the preparation equipment and industrial application of immobilized enzymes in the prior art, which cannot meet the requirements of the industrial production and application of immobilized enzymes or cells. In order to solve the above technical problems, the present invention proposes An immobilization device for producing immobilized enzymes or cells is disclosed, which comprises from top to bottom: a mixer 1 for mixing and dissolving materials, a material distributor 2, a titrator 3 and a curing box 4; Solution preparation, immobilized carrier and microbial cell (or enzyme) mixed solution preparation, immobilized enzyme (or cell) titration and curing functions are integrated, and immobilized enzymes are produced in batches. See details figure 1 .

[0075] Wherein, the material distributor 2 is a three-way diverter valve, and the three-way diverter valve includes an inlet port, an outlet port and a r...

Embodiment 2

[0085] A method for the industrial production of immobilized sucrose isomerase utilizing the immobilized device in Example 1, comprising the steps of:

[0086] (1) Prepare 6% calcium chloride sucrose solution (cross-linking curing agent solution): close the outlet control valve 21 and the reversing port control valve 22 of the material distributor 2, and connect the reversing port control valve with one end of a silicone tube 22, the other end is connected in the curing box 4, close the water outlet 407 of the curing box 4; open the shielding cover 14 of the mixer 1, add 6% (W / V) calcium chloride, 30 % (W / V) white granulated sugar, then open the water inlet valve 15 and add 50L of water; finally, adjust the position of the agitator 12, cover the cover plate 14, turn on the motor 13 to stir and dissolve the crosslinking curing agent solution; the material dissolves After completion, turn off the motor 13, open the reversing port control valve 22 of the material distributor 2, a...

Embodiment 3

[0093] A method for the industrial production of immobilized sucrose isomerase utilizing an immobilized device, comprising the steps of:

[0094] (1) Prepare 3% calcium chloride sucrose solution (cross-linking curing agent solution): close the material distributor 2 outlet control valve 21 and the reversing port control valve 22, and connect the reversing port control valve 22 with one end of a silicone tube , the other end is connected in the curing box 4, close the curing box 4 water outlet 407; open the cover 14 of the mixer 1, add 3% (W / V) calcium chloride, 25% calcium chloride, 25% calcium chloride in the container 11 of the mixer 1 (W / V) white granulated sugar, then open the water inlet valve 15 and add 50L of water; finally, adjust the position of the agitator 12, cover the cover plate 14, turn on the motor 13 to stir and dissolve the crosslinking curing agent solution; the material dissolves completely Finally, turn off the motor 13, open the reversing port control val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com