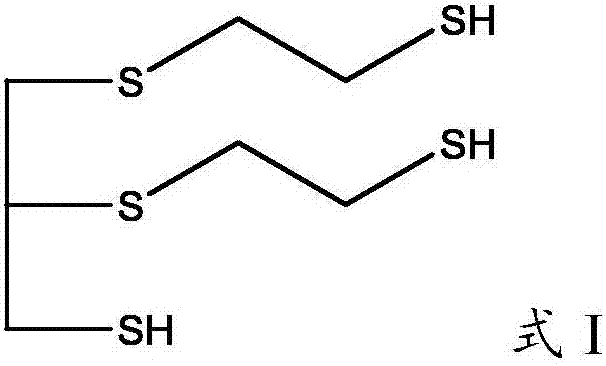

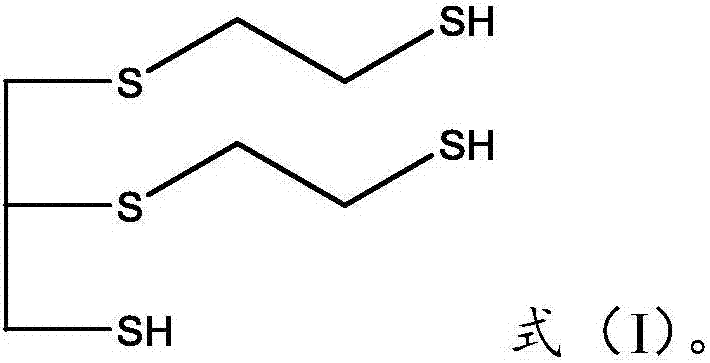

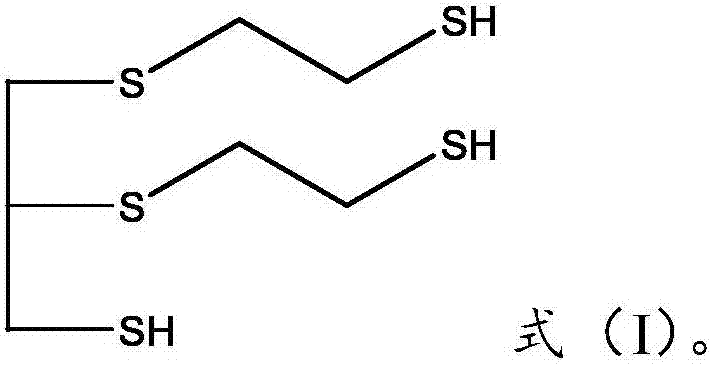

Post-treatment method of multi-sulfhydryl compound crude product

A technology for polythiol compounds and polythiol compounds is applied in the field of post-processing of crude polythiol compounds, which can solve the problems of high chromaticity of products, unfavorable optical resins and the like, and achieve high light transmittance, low chromaticity, and yellowness index. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Mercaptoethanol (3.0 molar equivalents) and epichlorohydrin (1.2 molar equivalents) were added to 25% sodium hydroxide (1.6 molar equivalents) aqueous solution, and the temperature was controlled to -10°C and the addition time was 2 hours to obtain the triol . Then, thiourea (4.8 molar equivalent) and 35% hydrochloric acid (7.8 molar equivalent) were added and mixed, and heated to 100° C. for reaction for 3 hours to obtain an intermediate product. The intermediate product was added to 40% sodium hydroxide aqueous solution (6.6 molar equivalents) and hydrolyzed at 70°C for 2 hours to obtain a crude product, washed with water, leaving only the oil phase, adding 1% of the crude mass of sodium hydroxide, and vacuuming at 70°C Dehydrated. The dehydrated mixture was mixed with diatomaceous earth with a crude quality of 2%, stirred evenly, and filtered to obtain a colorless and transparent product. The color of the product was 8 Hazen.

[0053] Preparation of optical resin:

[0...

Embodiment 2

[0056] Mercaptoethanol (1.6 molar equivalent) and epichlorohydrin (0.8 molar equivalent) were added to a 38% aqueous solution of sodium hydroxide (1.0 molar equivalent) successively, and the temperature was controlled to 0° C. and the addition time was 2 hours to obtain the triol. Then thiourea (3.6 molar equivalent) and 25% hydrochloric acid (4.0 molar equivalent) were added and mixed, and heated to 115° C. for reaction for 5 hours to obtain an intermediate product. The intermediate product was added to a 30% sodium hydroxide aqueous solution (5.2 molar equivalent) to hydrolyze at 50°C for 3 hours to obtain a crude product, washed with water, leaving only the oil phase, added with 5% crude sodium sulfite, and dehydrated at 60°C under vacuum . The dehydrated mixture was mixed with activated carbon with a crude quality of 5%, stirred evenly, and filtered to obtain a colorless and transparent product. The color of the product was detected to be 12 Hazen.

[0057] Using this polyme...

Embodiment 3

[0059] Mercaptoethanol (3.5 molar equivalent) and epichlorohydrin (1.5 molar equivalent) were added to a 30% potassium hydroxide (1.7 molar equivalent) aqueous solution, and the temperature was controlled to 5° C. and the addition time was 3 hours to obtain the triol. Then, thiourea (6.6 molar equivalents) and 40% sulfuric acid (11 molar equivalents) were added and mixed, and heated to 150° C. to react for 4 hours to obtain an intermediate product. The intermediate product was added to a 40% potassium hydroxide aqueous solution (9.5 molar equivalent) to hydrolyze at 70°C for 2 hours to obtain a crude product, washed with water, leaving only the oil phase, adding 2% crude sodium bisulfite at 85°C Perform vacuum dehydration. The dehydrated mixture was mixed with attapulgite with a crude quality of 2%, stirred evenly, and filtered to obtain a colorless and transparent product, and the color of the product was 10 Hazen.

[0060] Using this polymercapto compound, an optical resin was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com